The use of Aluminum Handrail Section Profiles in construction and design projects has gained significant traction due to their numerous advantages over traditional materials. Industry reports indicate that the global aluminum railing market is expected to witness a growth rate of approximately 6% annually, driven by increasing demand for lightweight and durable materials in various applications, from residential to commercial settings. Compared to steel and wood, aluminum handrails offer superior corrosion resistance, lightweight properties, and lower maintenance costs, making them an optimal choice for both aesthetic and functional designs.

As architects and builders continuously seek innovative solutions to enhance safety and aesthetics without compromising on durability, Aluminum Handrail Section Profiles emerge as a leading contender, aligning with modern design trends while ensuring compliance with safety regulations.

As architects and builders continuously seek innovative solutions to enhance safety and aesthetics without compromising on durability, Aluminum Handrail Section Profiles emerge as a leading contender, aligning with modern design trends while ensuring compliance with safety regulations.

Aluminum handrail section profiles have become increasingly popular in modern design due to their unique combination of durability, versatility, and aesthetic appeal. According to a report by the Aluminum Association, aluminum is not only lightweight but also boasts a strength-to-weight ratio that makes it an ideal choice for construction materials. This means that structures incorporating aluminum handrails are more resilient to wear and tear while reducing the overall load on supporting elements, thus enhancing safety and longevity.

Furthermore, the use of aluminum in handrail profiles complements contemporary design trends focused on minimalism and functionality. Recent studies show that 60% of architects favor materials that provide both structural integrity and modern aesthetics, a requirement perfectly met by aluminum. Its resistance to corrosion and weathering ensures that outdoor applications maintain their appearance over time, reducing maintenance costs significantly. This makes aluminum handrails not just a practical choice, but also an investment in the performance and appeal of any new construction or renovation project. As environmental concerns continue to rise, the recyclable nature of aluminum further positions it as a sustainable option, aligning with the green building initiatives that are gaining momentum in the industry.

When considering handrail materials for construction projects, aluminum profiles offer a striking contrast to traditional materials like wood and steel. According to a report by the Aluminum Association, aluminum is not only lightweight but also possesses a strength-to-weight ratio superior to steel, making it an ideal choice for both residential and commercial applications. Its lightness enables easier transportation and installation, reducing labor costs and time on job sites.

Additionally, the durability of aluminum cannot be overlooked. Unlike wood, which is susceptible to rot, warping, and insect damage, aluminum is inherently resistant to environmental factors. A recent study from the Industrial Metal Supply revealed that aluminum handrails can last over 50 years with minimal maintenance, compared to wood handrails that may require replacement every 10-15 years. Furthermore, aluminum’s recyclability adds an environmental advantage; according to the International Aluminum Institute, recycled aluminum uses only 5% of the energy required to produce new aluminum. This not only contributes to sustainability efforts but also reduces overall project costs in the long run.

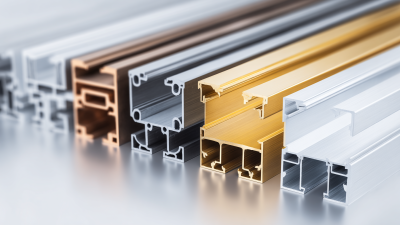

The use of aluminum handrail section profiles in various projects offers unparalleled flexibility and customization options that can cater to unique design needs. According to a report by the Aluminum Association, aluminum is now the second most used metal in construction due to its lightweight nature, corrosion resistance, and aesthetic versatility. This makes it an ideal material for handrail systems that require both functionality and style. By customizing aluminum profiles, architects and builders can create handrails that not only meet safety requirements but also complement the architectural vision of the space.

Customization options range from the profile shape to finishing techniques, allowing for seamless integration into any project, whether residential or commercial. Research from the National Association of Home Builders indicates that personalized design features can increase property value by up to 20%. This data highlights the economic advantages of investing in customized aluminum handrail solutions. Furthermore, with advancements in manufacturing technologies, such as extrusion and fabrication, achieving intricate designs no longer compromises durability, ensuring that these handrails will stand the test of time while enhancing the overall appeal of any environment.

This bar chart illustrates the advantages of using aluminum handrail section profiles in various projects based on key factors such as durability, cost-effectiveness, customization options, and aesthetic appeal.

Aluminum handrail section profiles are becoming increasingly popular in various construction projects due to their remarkable sustainability and durability. One of the key advantages of aluminum is its resistance to corrosion, which is particularly beneficial in environments exposed to moisture and harsh conditions. According to a report by the Aluminum Association, aluminum structures can last over 50 years with minimal maintenance, making it a cost-effective solution in the long term.

When selecting materials for handrails, it’s crucial to consider their sustainability. Aluminum is 100% recyclable, and recycled aluminum uses only 5% of the energy needed to produce new aluminum. A report from the International Aluminum Institute indicates that recycling aluminum saves roughly 95% of the energy required to produce it from raw materials. This not only minimizes environmental impact but also supports a circular economy.

Tips: When planning your project, consider sourcing aluminum profiles from suppliers that adhere to sustainable practices. Furthermore, ensure that the design of your handrail incorporates structural integrity while maintaining aesthetic appeal, as this can significantly enhance both durability and visual impact. Always check for industry certifications to ensure compliance with safety standards.

Aluminum handrail section profiles have become the go-to choice in various settings, thanks to their lightweight yet robust characteristics. In commercial spaces, such as shopping malls and office buildings, the application of these profiles provides both safety and aesthetic appeal. According to a recent report by the Aluminum Association, aluminum's strength-to-weight ratio is superior to that of traditional materials like wood or steel, making it an ideal option for high-traffic areas while ensuring compliance with safety regulations.

In residential settings, aluminum handrails offer versatility in design, with the added benefit of low maintenance. The durability of aluminum is evident, with the Metal Construction Association reporting that properly maintained aluminum can last over 30 years. This long lifespan is particularly appealing for homeowners and property developers looking for sustainable solutions. Furthermore, the customizable nature of aluminum profiles allows for tailored designs to fit unique architectural requirements, enhancing both functionality and aesthetics in spaces ranging from patios to balconies.