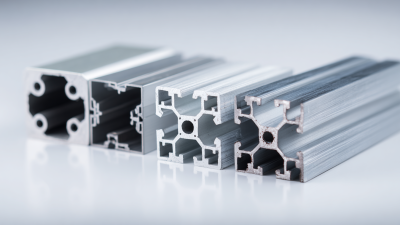

The global aluminium extrusion market is poised for significant growth in 2023, driven by a myriad of applications across various industries. Aluminium extrusion refers to the process of shaping aluminium alloys through a die to create complex profiles that are lightweight yet strong. According to industry reports, the market for aluminium extrusion is projected to reach $100 billion by the end of the decade, reflecting a compound annual growth rate (CAGR) of approximately 5.3% from 2022 to 2030.

Key sectors such as construction, automotive, and consumer goods have increasingly adopted aluminium extrusion due to its versatility and eco-friendliness. For instance, the construction industry alone is expected to account for over 35% of the market share, driven by a growing demand for energy-efficient and sustainable building materials.

Furthermore, advancements in manufacturing technologies and an increasing focus on recycling practices are enhancing the attractiveness of aluminium extrusion as a preferred choice in product development.

This article explores the top 10 aluminium extrusion applications that are steering industry growth in 2023, highlighting how these innovative uses of aluminium are shaping the future across various sectors. By understanding these trends, stakeholders can better position themselves to capitalize on the burgeoning opportunities within the aluminium extrusion landscape.

The aluminium extrusion industry is experiencing significant growth in 2023, largely driven by emerging trends across various applications. According to a recent report by MarketsandMarkets, the global aluminium extrusion market is projected to reach USD 90 billion by 2025, growing at a CAGR of 5.3%. One of the primary drivers of this growth is the increasing demand for lightweight materials in the automotive and aerospace sectors. Manufacturers are increasingly adopting aluminium extrusions as a sustainable alternative to traditional materials, leading to enhanced fuel efficiency and reduced emissions.

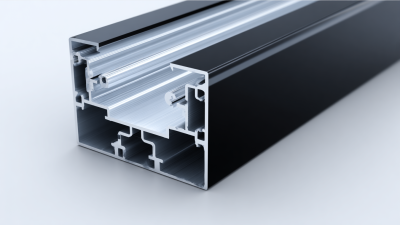

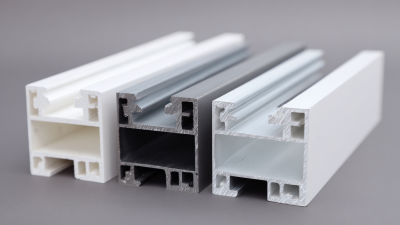

Another notable trend is the rising use of aluminium extrusions in the construction sector, driven by the growing emphasis on sustainable and energy-efficient building designs. The Global Aluminium Extrusion Market Analysis by CC Global indicates that the construction segment will witness a significant CAGR of over 6% between 2023 and 2028. Aluminium’s intrinsic properties, such as corrosion resistance and recyclability, make it an ideal choice for structural applications, window frames, and curtain wall systems. As urbanization accelerates, the demand for innovative, sustainable construction solutions continues to fuel the growth of aluminium extrusion applications, highlighting its pivotal role in driving industry advancement in the coming years.

The automotive sector has seen a remarkable transformation in recent years, largely driven by the innovative applications of aluminium extrusion. Manufacturers are increasingly turning to aluminium extrusions for components that combine lightweight properties with high strength, essential for improving fuel efficiency and reducing emissions. This shift is evident in the production of structural elements, chassis components, and heat exchangers, where aluminium not only enhances performance but also contributes to sustainability goals.

The demand for aluminium extrusion in automotive applications is further fueled by advancements in technology and design. For instance, the integration of aluminium extrusions in electric vehicles has become a key trend, as these vehicles require materials that can support their unique structural and thermal management needs. The ongoing research partnerships aimed at expanding aluminium use in the auto industry signify the commitment to innovative solutions that support both the automotive sector's growth and environmental sustainability initiatives. As the industry evolves, aluminium extrusion continues to play a pivotal role in shaping the future of automotive manufacturing and design.

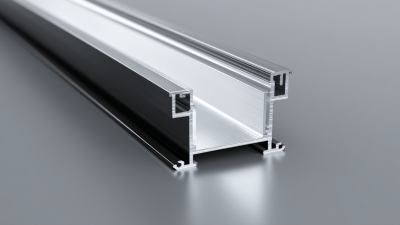

Aluminium extrusion plays a pivotal role in promoting sustainable building solutions, especially as the industry shifts towards environmentally friendly practices. The versatility of aluminium makes it an excellent choice for various structural applications, from window frames to roofing systems. Its lightweight nature and ability to be recycled without loss of quality significantly reduce the carbon footprint of construction projects, aligning with global sustainability goals. As demand for energy-efficient buildings grows, the use of aluminium extrusion is set to expand further.

Moreover, advancements in corrosion protection technologies for recycled aluminium are enhancing its appeal in the market. Despite the advantages of using secondary aluminium, challenges such as corrosion resistance have historically hindered its adoption. However, innovative solutions are being developed to overcome these obstacles, making aluminium extrusion a reliable and sustainable option for builders and manufacturers alike. This trend is expected to contribute to a steady growth in the aluminium extrusion market, reinforcing its role in sustainable construction practices.

The aerospace and defense industries have increasingly turned to aluminum extrusion as a vital component in their operations. This lightweight material offers exceptional strength-to-weight ratios and can be engineered to meet specific requirements, making it ideal for both aircraft and military vehicles.

Advances in aluminum extrusion technology enable the production of complex shapes and designs, leading to improvements in fuel efficiency and performance in air and space travel.

Moreover, the extruded aluminum market plays a critical role amid the ongoing expansion in aerospace and defense. The integration of AI and digital tools in manufacturing processes enhances the efficiency of aluminum production, allowing for faster turnaround times and reduced costs. However, the industry faces challenges such as tariffs on imports that can significantly impact pricing and supply chains. Addressing these tariff implications is crucial for fostering a robust aluminum extrusion market that supports continual growth in these sectors.

Aluminium extrusion has become a cornerstone in the electronics industry, enabling the development of lightweight, efficient, and durable components that meet modern technological demands. According to a recent report by the Aluminium Association, the global market for aluminium in electronics is projected to reach $27 billion by 2025, driven by the growing need for advanced materials in devices such as smartphones, laptops, and electric vehicles. The unique properties of aluminium, including its excellent thermal and electrical conductivity, alongside its recyclability, make it an ideal choice for manufacturers looking to innovate.

In 2023, the trend towards miniaturization in electronics has intensified, further propelling the use of aluminium extrusion. Companies are leveraging advanced extrusion processes to create complex, thin-walled sections that facilitate better heat dissipation in high-performance electronics. As per a market analysis by MarketsandMarkets, the aluminium extrusion segment in the electronics sector is expected to witness a compound annual growth rate (CAGR) of over 5% between 2023 and 2028. This growth is largely attributed to the increasing adoption of aluminium enclosures, heat sinks, and structural components that support the advancement of technologies such as 5G and IoT.

| Application | Description | Market Share % (2023) | Growth Rate % (2023) |

|---|---|---|---|

| Consumer Electronics | Applications in smartphones, laptops, and tablets. | 25 | 6 |

| Automotive Components | Lightweight structures for vehicle efficiency. | 20 | 8 |

| Building and Construction | Frameworks, facades, and roofing materials. | 18 | 5 |

| Electrical and Telecommunications | Cables, connectors, and housing. | 15 | 7 |

| Aerospace | Structural components and lightweight designs. | 10 | 4 |

| Packaging | Aluminium foil and containers for various products. | 8 | 3 |

| Robotics | Frames and structural components. | 5 | 6 |

| Marine Applications | Components for boats and ships. | 4 | 2 |

| Healthcare Equipment | Frames and housings for medical devices. | 3 | 3 |

| Furniture | Aluminium frames and structural components for furniture. | 2 | 2 |