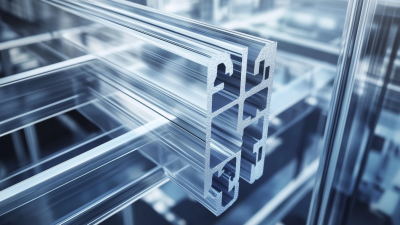

Aluminum Handle Extrusions have gained significant popularity in various manufacturing processes due to their lightweight, durability, and versatility. According to a recent industry report by the Aluminum Association, the demand for aluminum extrusions is projected to grow by 5% annually, driven by applications in automotive, construction, and consumer goods. However, manufacturers often encounter challenges during the production of aluminum handle extrusions, which can affect the efficiency and quality of the final products. Common issues include dimensional inconsistencies, surface imperfections, and difficulties in achieving the desired mechanical properties. Addressing these challenges is essential for manufacturers looking to optimize their processes and enhance product performance, making it crucial to explore effective solutions and best practices in the production of Aluminum Handle Extrusions.

In the manufacturing sector, achieving precision in aluminum handle extrusions is a complex task. It requires meticulous attention to detail, particularly in meeting tolerance standards that can significantly affect the final product's performance and quality. The challenges often arise from variations in material properties, environmental factors, and the intricacies of the extrusion process itself. Utilizing a data-driven approach to monitor and analyze these factors can enhance the ability to stay within tolerance limits, ultimately leading to improved production efficiency and product reliability.

Tip: Implementing real-time monitoring systems can help track deviations during the extrusion process. By capturing data on temperature, pressure, and material flow, manufacturers can make informed adjustments quickly, reducing waste and ensuring better compliance with tolerance standards.

Moreover, collaboration among design, engineering, and production teams can further address these challenges. By integrating feedback loops that utilize data analytics, teams can identify recurring issues and develop solutions proactively. This holistic approach not only streamlines the manufacturing process but also fosters innovation in creating aluminum extrusions that meet and exceed industry standards.

Tip: Conduct regular training sessions for your workforce on the importance of tolerance in extrusions and how data can play a role in their daily operations. Empowering employees with knowledge can lead to a more engaged workforce, committed to quality assurance and continuous improvement.

The complexity of design in aluminum handle extrusions significantly influences manufacturing efficiency. As manufacturers increasingly adopt advanced techniques such as 3D printing, they face challenges associated with intricate designs that require precise execution. In particular, the shift towards aluminum materials tailored for additive manufacturing introduces flexibility in design but simultaneously complicates the process due to factors such as structural integrity and material behavior under varied conditions.

Additionally, the use of smart extrusion techniques can optimize production processes by predicting grain size and minimizing defects. Implementing data-driven strategies to refine the properties of aluminum extrusions not only enhances the mechanical qualities of the final product but also addresses manufacturing bottlenecks that arise from complex designs. By leveraging innovations in lightweight materials and multi-material additive manufacturing, companies can improve their handling of aluminum extrusions, ensuring sustainable development while balancing efficiency and design intricacies.

Aluminum extrusions are widely used in manufacturing due to their lightweight and strong characteristics. However, the production process is not without its challenges. A quantitative analysis of rejection rates in aluminum handle extrusions reveals that common defects can significantly impact product quality and overall efficiency. Factors such as improper die design, temperature fluctuations, and inconsistent material quality can lead to defects like surface blemishes, dimensional inaccuracies, and internal voids.

In a recent analysis, it was found that nearly 20% of aluminum extrusions were rejected during quality control. The most significant defect observed was dimensional non-conformity, accounting for about 50% of the total rejections. This issue often arises from inadequate control over the extrusion process parameters, highlighting the need for stringent monitoring and better die design practices. Additionally, surface imperfections due to the oxidation or contamination during the pre-treatment phase also contributed to the rejection rates, emphasizing the importance of maintaining a clean manufacturing environment. Addressing these issues through improved techniques can lead to reduced rejection rates, which in turn enhances productivity and profitability in aluminum extrusion manufacturing.

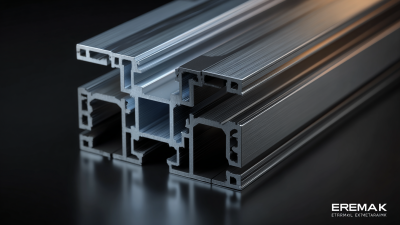

The quality of aluminum extrusions is heavily influenced by material selection, particularly the alloy composition used in manufacturing processes. According to an industry report by the Aluminum Association, variations in alloying elements can lead to significant differences in mechanical properties, corrosion resistance, and overall extrudability. For instance, aluminum alloys such as 6061 and 6063 are commonly used due to their excellent response to extrusion and welding. However, slight changes in silicon or magnesium content can dramatically alter the extrusion's strength and workability, which could lead to defects such as cracking or inadequate surface finish.

To ensure optimal extrusion quality, it's essential to carefully consider alloy choices based on the specific application requirements. For example, a higher magnesium content in 6xxx series alloys may enhance strength and corrosion resistance but can also make the extrusions more challenging to process.

**Tip 1:** Always consult with material engineers to select the right alloy for your project, as improper material selection can result in costly defects and rework.

**Tip 2:** Utilize advanced simulation software during the design phase to predict how different alloy compositions will perform in the extrusion process, helping to mitigate potential issues before they arise.

By understanding the impact of alloy composition, manufacturers can improve extrusion quality and maintain production efficiency.

| Alloy Type | Tensile Strength (MPa) | Elongation (%) | Formability Rating | Common Defects |

|---|---|---|---|---|

| 6061 | 310 | 12 | Good | Waviness, Incomplete Fill |

| 6063 | 260 | 10 | Excellent | Surface Imperfections |

| 6005 | 290 | 10 | Good | Cracks, Dimensional Tolerances |

| 6082 | 320 | 11 | Good | Brittleness, Grain Structure Issues |

| 2024 | 480 | 5 | Fair | Corrosion, Surface Cracking |

In the manufacturing sector, particularly in aluminum extrusion processes, production downtime remains a critical concern. A recent report by the International Aluminum Institute indicates that unplanned outages can account for more than 30% of total downtime in production lines. Factors contributing to these outages often include equipment failures, supply chain disruptions, and external events such as power outages. This was starkly illustrated in April 2025 when a severe power outage across the Iberian Peninsula disrupted operations at a major aluminum complex, leading to significant production delays.

To mitigate these challenges, manufacturers are increasingly adopting comprehensive risk management strategies. According to a study by the Aluminum Association, companies that implement predictive maintenance and invest in backup power solutions can reduce downtime by up to 25%. Additionally, diversifying energy sources and enhancing the resilience of supply chains are crucial steps in maintaining operational continuity. As the industry becomes more data-driven, the integration of advanced analytics into production processes will play a key role in identifying vulnerabilities and optimizing performance, ultimately leading to a more robust manufacturing ecosystem.