In the realm of construction and manufacturing, the selection of materials significantly influences the overall quality and efficiency of any project. Among the myriad options available, the Aluminum L Shape Angle has emerged as a pivotal choice for various applications due to its unique properties and versatility. According to a report by the Aluminum Association, the use of aluminum in building and construction has increased by 40% over the last decade, reinforcing its status as a preferred material among industry professionals. This shift highlights the growing recognition of aluminum's durability, lightweight nature, and cost-effectiveness, making the Aluminum L Shape Angle an optimal selection for engineers and architects alike.

Experts in the field emphasize the importance of this material as well. John D. Miller, a leading structural engineer and materials expert, stated, “The Aluminum L Shape Angle is not just a building material; it’s a cornerstone of innovation in design.” His insights underscore the role of aluminum angles in enhancing structural integrity while allowing for greater design flexibility.

As we look toward the future of construction in 2025 and beyond, integrating Aluminum L Shape Angle into projects can provide enhanced performance, sustainability, and aesthetic appeal, ensuring that modern structures meet both functional and environmental standards.

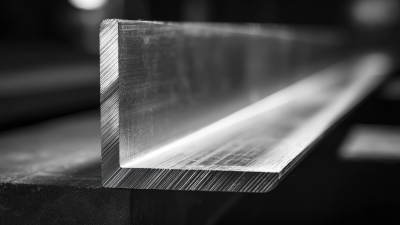

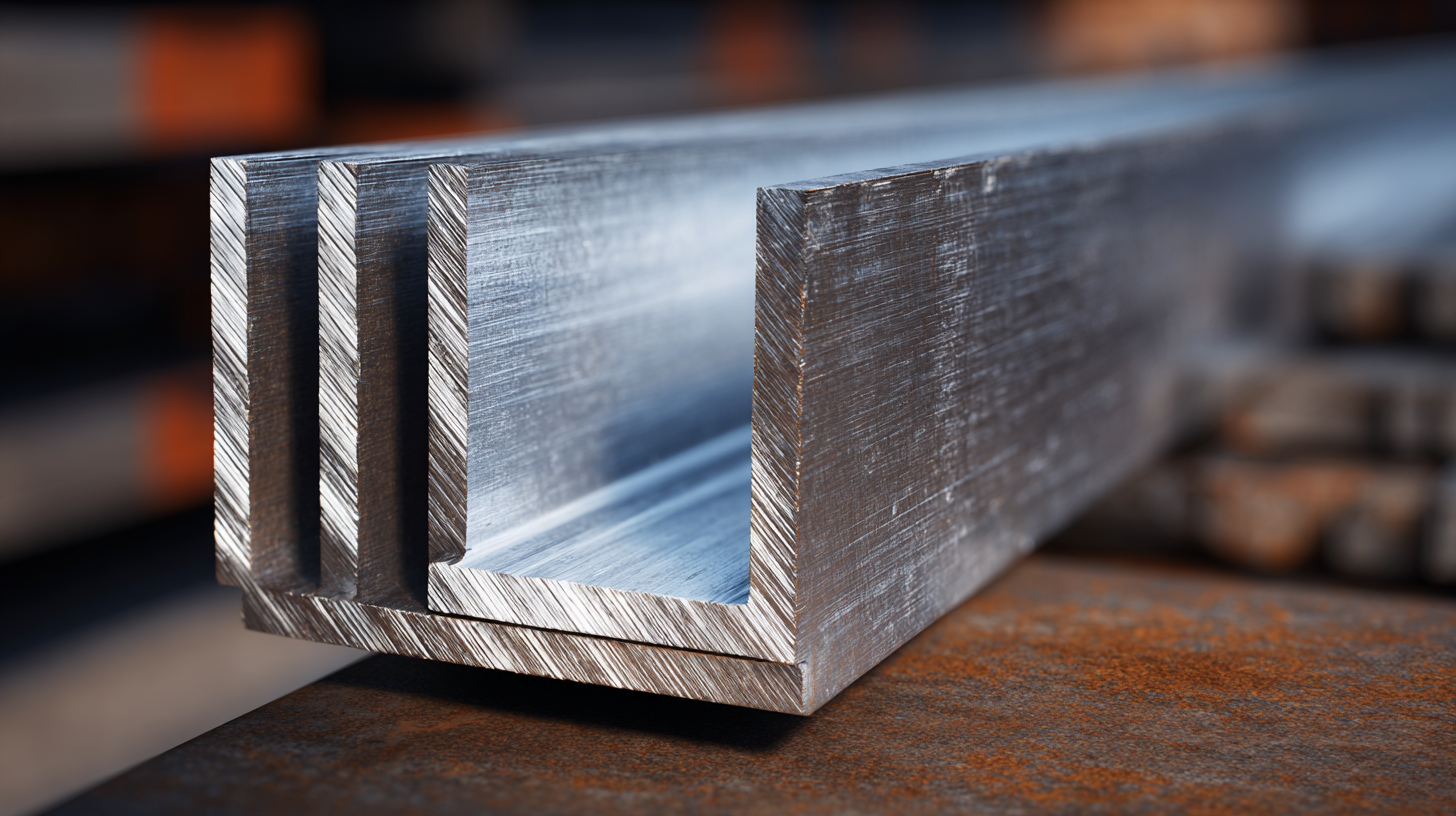

Aluminum L shape angles offer numerous advantages that make them an ideal choice for construction projects. First and foremost, their lightweight nature facilitates ease of handling and installation, reducing labor costs and the need for heavy machinery. Unlike steel, aluminum resists rust and corrosion, ensuring a longer lifespan and lower maintenance requirements. This durability is essential for structures exposed to varying weather conditions, significantly enhancing the overall integrity of construction.

Aluminum L shape angles offer numerous advantages that make them an ideal choice for construction projects. First and foremost, their lightweight nature facilitates ease of handling and installation, reducing labor costs and the need for heavy machinery. Unlike steel, aluminum resists rust and corrosion, ensuring a longer lifespan and lower maintenance requirements. This durability is essential for structures exposed to varying weather conditions, significantly enhancing the overall integrity of construction.

Additionally, aluminum's malleability allows for versatile applications in design, enabling architects and builders to explore innovative solutions. The aesthetic appeal of aluminum contributes to modern architectural designs, seamlessly integrating functionality with style. Moreover, using aluminum L shape angles promotes sustainability; they are fully recyclable, which aligns with eco-friendly building practices. By incorporating aluminum in construction, projects not only benefit from functional advantages but also support environmental responsibility.

When evaluating materials for L shape angles,

aluminum stands out due to its unique blend of properties that provide distinct advantages over alternatives like steel and plastic. Aluminum is inherently lightweight, making it easier to handle and install without compromising strength.

Unlike steel, which can be prone to rust and corrosion, aluminum possesses excellent resistance to these elements, ensuring longevity even in challenging environments. This durability translates to lower maintenance costs over time, making aluminum a cost-effective choice for projects where reliability is paramount.

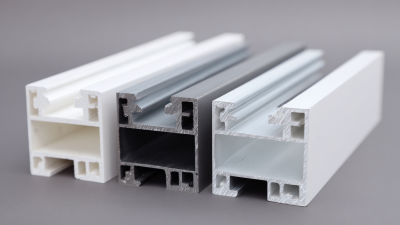

In comparison to plastic, aluminum offers

superior rigidity and load-bearing capacity, crucial for structural applications. While plastic may be less expensive upfront, it is often less durable and can deform under stress or exposure to extreme temperatures. Additionally, aluminum’s recyclability adds an environmental benefit that plastic cannot match, allowing for a more sustainable approach to construction.

Thus, for projects requiring a balance of strength, durability, and sustainability, aluminum L shape angles emerge as an unparalleled option in the material landscape.

Aluminum L shape angles offer unparalleled design flexibility that significantly enhances project creativity. According to the Aluminum Association, aluminum's lightweight nature, combined with its high strength-to-weight ratio, allows designers to create intricate structures without the limitations associated with heavier materials.

This adaptability especially shines in architectural applications, where unique shapes and forms can be achieved, enabling architects to push the boundaries of their designs while maintaining structural integrity.

Furthermore, a report by MarketsandMarkets revealed that the global aluminum market is projected to reach 174 million metric tons by 2026, largely driven by its increasing application in the construction industry. As designers increasingly turn towards sustainable materials, aluminum's recyclability and low environmental impact make it a popular choice for innovative projects. The versatility of aluminum L shape angles helps engineers and designers customize their solutions to meet diverse needs, whether in residential, commercial, or industrial settings. This trend indicates a growing recognition of aluminum's pivotal role in shaping the future of construction and design.

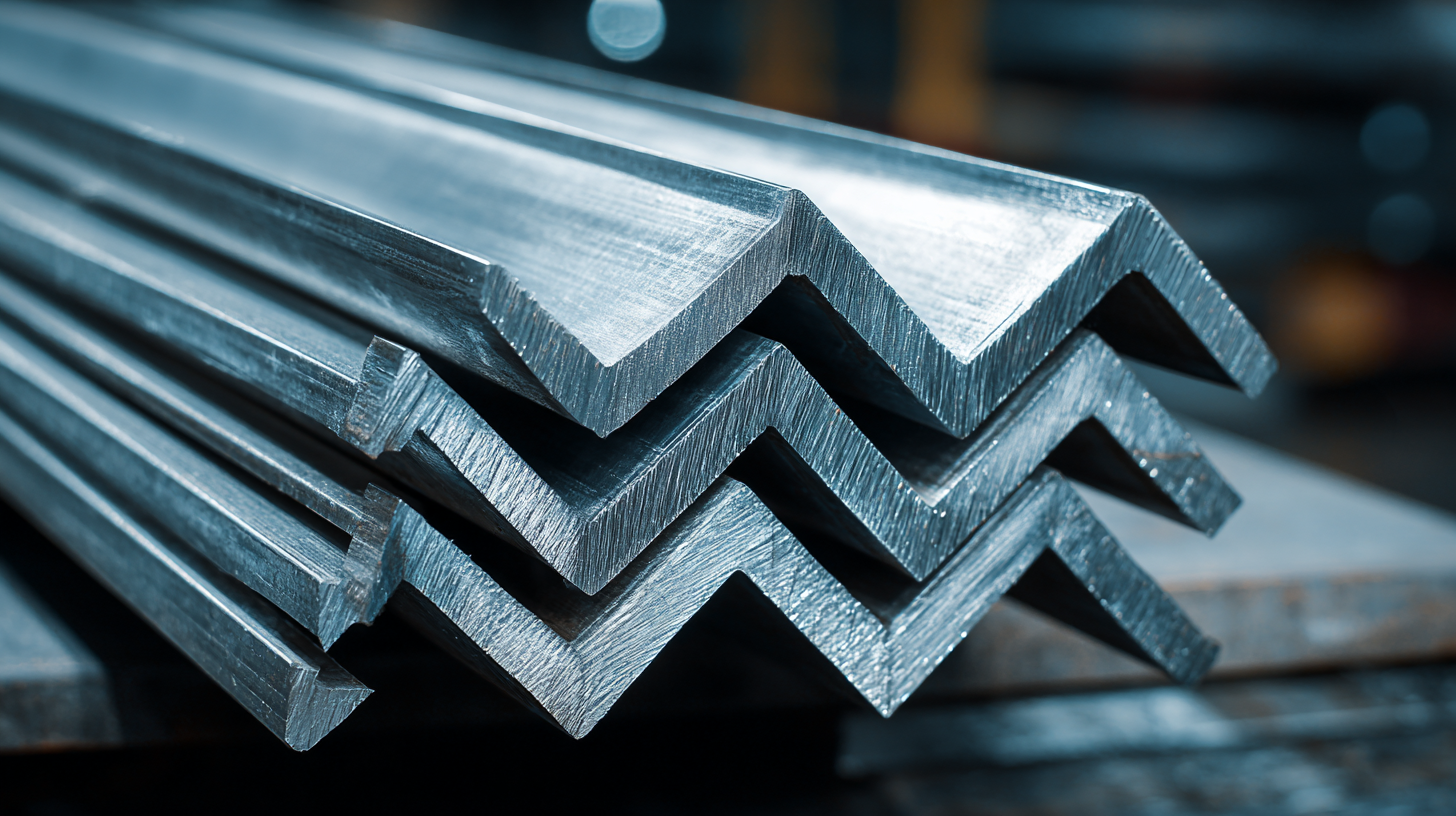

Aluminum L shape angles are increasingly recognized for their durability and low maintenance, making them an excellent choice for a variety of projects. According to industry reports, aluminum has a natural resistance to corrosion due to its protective oxide layer, which makes it ideal for both indoor and outdoor use. In fact, studies show that aluminum components can last over 50 years without significant degradation, even in harsh environments. This longevity significantly reduces the need for frequent replacements, ultimately lowering long-term costs.

Moreover, the lightweight nature of aluminum facilitates easier handling and installation, further enhancing its appeal. A recent survey indicated that over 70% of construction professionals prefer aluminum materials due to their strength-to-weight ratio, enabling robust designs without the burden of excessive weights. This attribute is crucial not only in construction but also in industries where equipment mobility is paramount, such as home fitness. As consumers increasingly prioritize effectiveness and efficiency in their projects, the long-term advantages offered by aluminum L shape angles make them a fitting solution for both residential and commercial applications.

When considering budget-friendly materials for construction and renovation projects, aluminum L shape angles stand out for their cost-effectiveness. According to industry reports, aluminum offers a balance of strength and lightweight properties that significantly reduce shipping and handling costs, making it a preferred choice for many contractors. The average cost of aluminum L angles is reported to be around 20-30% lower than equivalent steel products, without compromising durability. This is particularly important for projects that require structural integrity and resistance to corrosion.

Moreover, when comparing to other materials, such as wood or plastic, the longevity and low maintenance needs of aluminum can lead to significant savings over time. For example, aluminum does not warp or rot, ensuring that projects using L shape angles maintain their structural integrity longer than those relying on more traditional materials. This aligns with current trends in budget-conscious building, where efficient material use is crucial in managing costs effectively. With the increasing demand for sustainable building practices, aluminum's recyclability further enhances its value proposition, offering a green solution that appeals to environmentally conscious stakeholders.