Aluminum Handle Extrusions have become increasingly popular in various industries, offering a myriad of advantages that enhance both functionality and aesthetic appeal in projects. These extrusions are known for their excellent strength-to-weight ratio, making them an ideal choice for applications where durability and lightweight properties are crucial. As projects evolve, the demand for reliable materials that can withstand daily use while maintaining a sleek appearance continues to grow.

In this article, we will explore the top ten benefits of Aluminum Handle Extrusions, highlighting why they are an exceptional option for your next project. From their corrosion resistance and ease of fabrication to their versatility in design, aluminum extrusions present an innovative solution for a wide range of applications. Whether you are working on furniture, cabinetry, or custom manufacturing, understanding the advantages of Aluminum Handle Extrusions can greatly influence the success and longevity of your designs. Join us as we delve into the key benefits that make these extrusions a smart choice for modern projects.

Aluminum handle extrusions offer numerous advantages in manufacturing, primarily due to their lightweight nature, which can significantly enhance product efficiency and performance. According to industry reports, aluminum is about one-third the weight of steel without sacrificing strength, making it an ideal material for various applications. This lightweight characteristic not only reduces shipping costs but also lowers production energy consumption, which is increasingly vital in today’s sustainability-focused market.

Moreover, the superior corrosion resistance of aluminum ensures longevity and reduces maintenance costs. As highlighted by recent studies, aluminum handles can last up to three times longer than traditional materials in harsh environments. This durability translates to fewer replacements and reduced waste, aligning with eco-friendly manufacturing practices.

**Tip:** When designing projects that utilize aluminum handle extrusions, it's essential to account for specific environmental conditions, as this can influence the selection of alloy grades for enhanced performance.

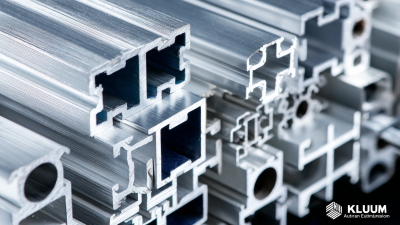

Additionally, incorporating aluminum in your manufacturing can lead to more innovative designs due to its versatility. The ability to produce complex shapes through extrusion techniques allows for tailored solutions that can seamlessly integrate with various products, catering specifically to unique project requirements.

**Tip:** Consider utilizing simulation software during the design phase to visualize and optimize the handle extrusion before manufacturing, ensuring functionality and aesthetic appeal are balanced effectively.

| Benefit | Description | Application Examples |

|---|---|---|

| Lightweight | Aluminum is significantly lighter than steel, making it easier to handle during manufacturing processes. | Automotive components, portable tools |

| Corrosion Resistance | Aluminum is naturally resistant to oxidation, providing longevity and durability. | Outdoor equipment, marine applications |

| Customizable Shapes | Extrusions can be created in various shapes to meet specific design requirements. | Custom handle designs, furniture |

| Recyclable Material | Aluminum can be recycled without losing its properties, supporting sustainability efforts. | Green building projects |

| Excellent Strength-to-Weight Ratio | Aluminum provides significant strength while minimizing weight. | Aerospace applications, machinery components |

| Good Thermal Conductivity | Aluminum efficiently dissipates heat, useful in many applications. | Heat sinks, automotive radiators |

| Ease of Machining | Aluminum can be machined, welded, and anodized easily. | Manufacturing of intricate designs |

| Cost-Effective | Due to its abundance and recyclability, aluminum is often a cost-effective material choice. | High-volume production items |

| Aesthetic Appeal | Aluminum can be finished and anodized to provide an attractive appearance. | Consumer electronics, home appliances |

Aluminum handle extrusions are increasingly popular in various projects due to their enhanced durability and resistance to corrosion. When compared to traditional materials, aluminum handles offer a long-lasting solution that withstands the elements, making them ideal for outdoor applications. The lightweight nature of aluminum also means that these handles can be easily incorporated into designs without adding significant weight, which is essential for products like doors, drawers, and machinery.

For those considering aluminum handles, it’s important to choose the right finish to maximize their corrosion resistance. Anodizing is a common process that not only protects the aluminum but also provides an aesthetically appealing surface. Additionally, applying a protective coating can further enhance the lifespan of your aluminum components.

Tips: Always consider the environment where the handle will be used. For coastal areas, opting for marine-grade aluminum may be advantageous due to its superior resistance to saltwater corrosion. Regular maintenance, such as cleaning and periodic inspection, can go a long way in prolonging the life of your aluminum handles.

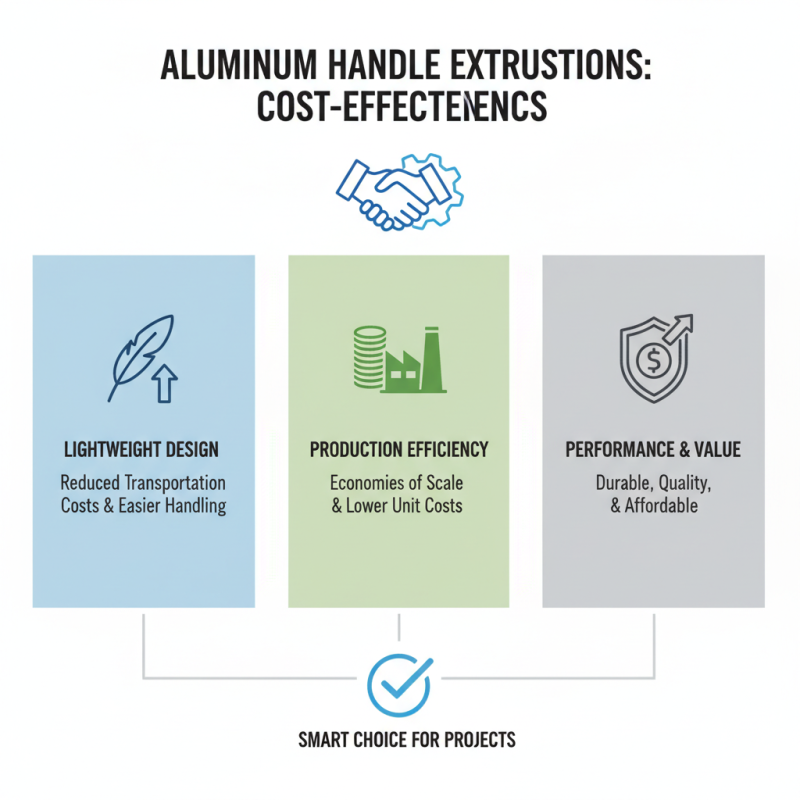

When it comes to project design and implementation, the choice of materials can significantly impact both performance and cost. Aluminum handle extrusions offer a compelling cost-effectiveness that makes them a popular option across various industries. One of the primary reasons for this is their lightweight nature, which reduces transportation costs and makes handling easier during installation. The production process of aluminum extrusions also allows for economies of scale, resulting in lower unit costs without compromising quality.

Moreover, aluminum handle extrusions are known for their durability and resistance to corrosion. This longevity means that projects requiring minimal maintenance can save on ongoing repair or replacement costs. Additionally, the versatility of aluminum allows it to be easily fabricated into intricate designs, reducing waste and optimizing resource use. By integrating aluminum extrusions into projects, not only can companies enjoy upfront savings, but they can also ensure greater efficiency and longevity over the lifespan of the product, further enhancing overall cost-effectiveness.

Aluminum handle extrusions offer remarkable versatility, making them ideal for a wide range of applications across multiple industries. Their lightweight nature combined with excellent strength and durability enables designers and engineers to incorporate them into various projects seamlessly. Whether for automotive interiors, furniture design, or consumer electronics, aluminum handle extrusions can be easily adapted to meet specific design aesthetics and functional requirements.

Aluminum handle extrusions offer remarkable versatility, making them ideal for a wide range of applications across multiple industries. Their lightweight nature combined with excellent strength and durability enables designers and engineers to incorporate them into various projects seamlessly. Whether for automotive interiors, furniture design, or consumer electronics, aluminum handle extrusions can be easily adapted to meet specific design aesthetics and functional requirements.

In addition to their physical properties, aluminum handle extrusions can be tailored through various finishing techniques, such as anodizing or powder coating, to enhance their appearance and resistance to corrosion. This adaptability ensures that they not only perform well but also complement the visual appeal of the product they are part of. From kitchen cabinets and door handles to gym equipment and toolboxes, the application possibilities are vast, allowing for innovative designs that prioritize both functionality and style.

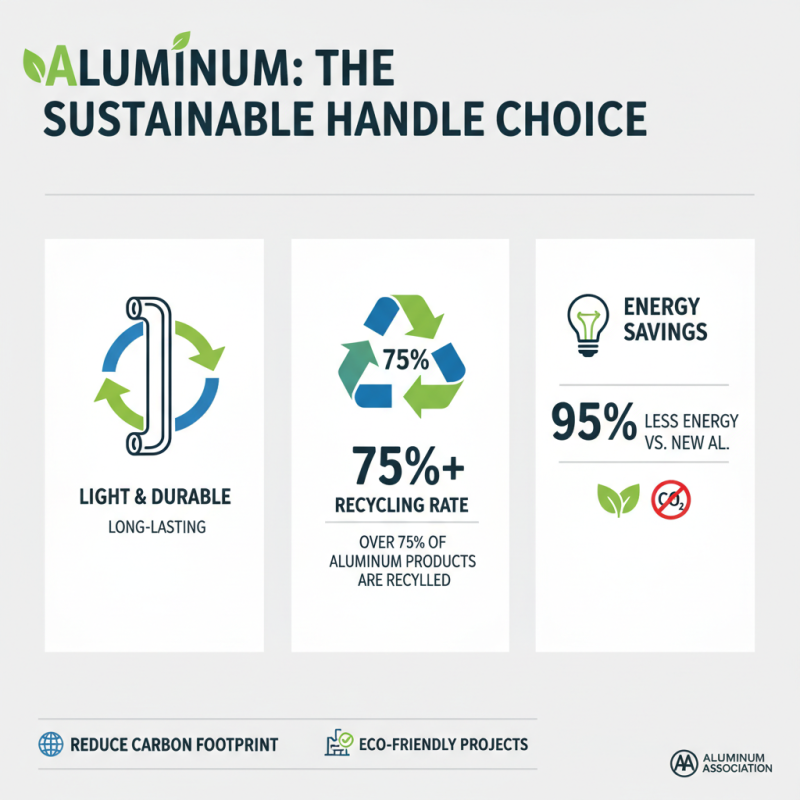

Aluminum is increasingly recognized as a sustainable and eco-friendly material in handle production. Not only is aluminum lightweight and durable, but it is also highly recyclable, with an impressive recycling rate of over 75% for aluminum products. According to the Aluminum Association, using recycled aluminum can save up to 95% of the energy required to produce new aluminum from raw materials. This significant energy saving reduces the carbon footprint associated with handle manufacturing, making aluminum a prime choice for environmentally conscious projects.

When embarking on handle production, consider sourcing aluminum from suppliers that focus on sustainable practices and CAC (closed-loop recycling) systems. This ensures that the material you use not only meets your project requirements but also adheres to the principles of sustainability. Additionally, choosing aluminum extrusions can lead to further resource efficiency, as this method minimizes waste during the manufacturing process.

Tip: To enhance the sustainability of your project, look for certification programs that verify the recycled content of your aluminum. This not only promotes responsible sourcing but also aids in meeting environmental standards and building a positive brand image. Incorporating aluminum handles can significantly contribute to green building initiatives, thus attracting a market segment that values sustainability.