In the realm of construction and manufacturing, the choice of materials plays a pivotal role in ensuring the success of any project. One such essential component is the Aluminum L Shape Angle, which has gained recognition for its versatility and strength in various applications. According to a report by MarketsandMarkets, the global aluminum market is expected to reach $182 billion by 2024, highlighting the increasing demand for aluminum products, especially in sectors like construction, automotive, and aerospace.

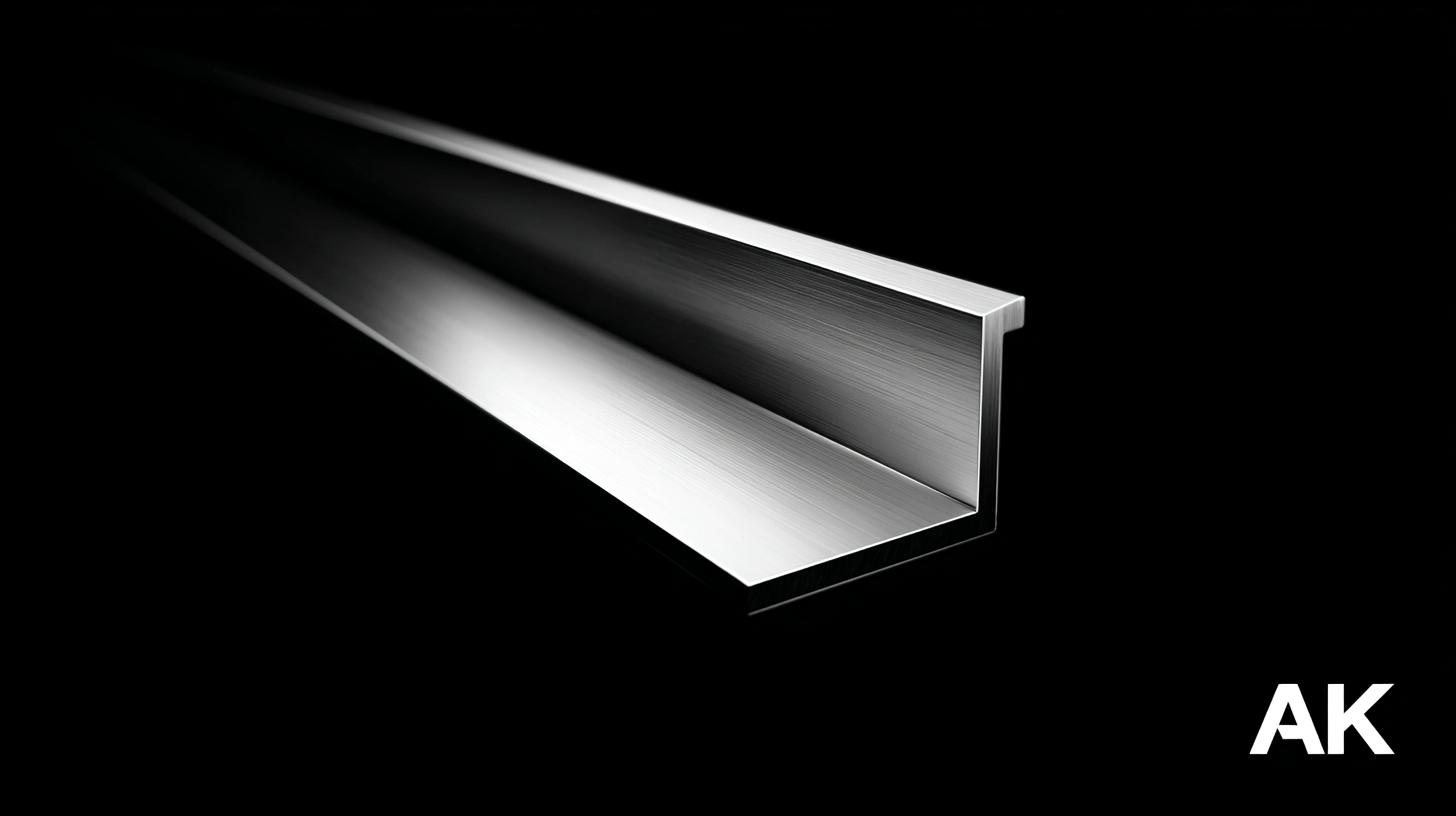

The unique properties of Aluminum L Shape Angles, including their lightweight nature and resistance to corrosion, make them an invaluable asset in projects ranging from structural supports to intricate architectural designs. By understanding the seven crucial reasons why incorporating Aluminum L Shape Angles in your next project can enhance both functionality and efficiency, you can make informed decisions that drive your success.

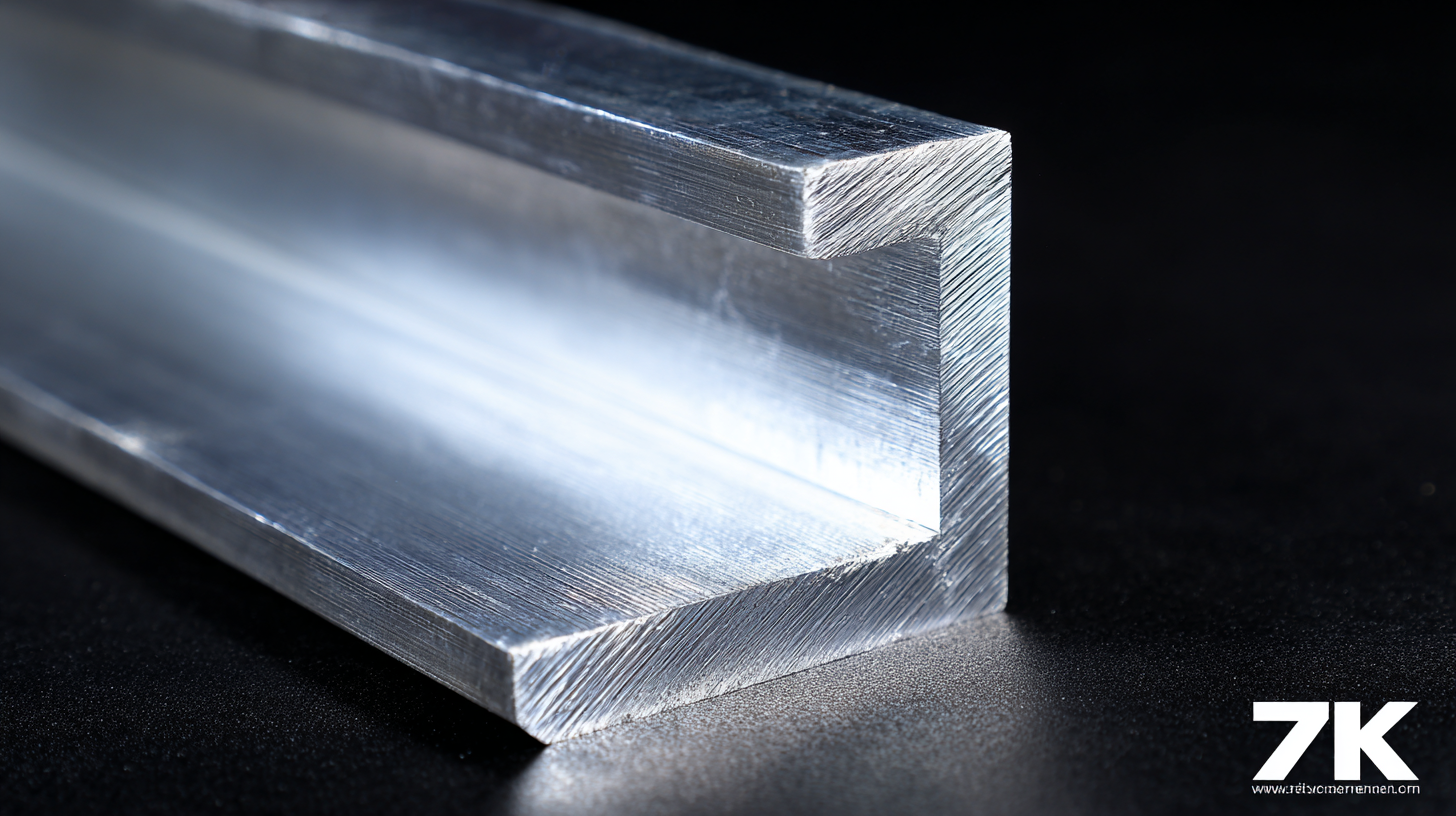

When embarking on your next construction project, the importance of selecting high-quality aluminum L shape angles cannot be overstated. These structural components not only provide vital support but also enhance the overall durability of your build. Aluminum is known for its lightweight yet robust properties, making it an ideal choice for a range of applications. By choosing high-quality angles, you ensure that your project not only withstands the test of time but also remains aesthetically pleasing.

When selecting aluminum L shape angles, consider the corrosion resistance of the material. This property extends the lifespan of the angles, especially in outdoor or humid environments. Additionally, opt for angles with a thick profile for superior load-bearing capacity. Don't forget to check for compliance with industry standards, ensuring that the angles you choose meet the required specifications for safety and performance.

Always prioritize reputable suppliers when sourcing your aluminum angles. Doing so can save you time and money in the long run, as quality products typically require less maintenance and fewer replacements. Moreover, investing in high-quality aluminum L shape angles can significantly improve the structural integrity of your project, leading to fewer issues down the line.

When selecting the best aluminum L shape angle for your next project, understanding key features is crucial. First, consider the material grade; aluminum alloys vary in strength and corrosion resistance. High-grade alloys like 6061 or 6063 are popular choices due to their excellent mechanical properties, making them ideal for structural applications. Additionally, look for angles that are anodized or coated to enhance their durability and aesthetic appeal, ensuring they withstand environmental factors without compromising performance.

Another important metric to keep in mind is the dimensions of the aluminum L shape angle. Proper sizing not only affects the structural integrity of your project but also its overall appearance. For precision, confirm the angle's leg lengths and thickness; these measurements dictate how it will integrate with other materials. Lastly, pay attention to manufacturing tolerances, as precise angles dictate how well components will fit together, leading to smoother assembly and improved results in your construction endeavors. Selecting the right aluminum L shape angle based on these features will ultimately lead to a more successful project outcome.

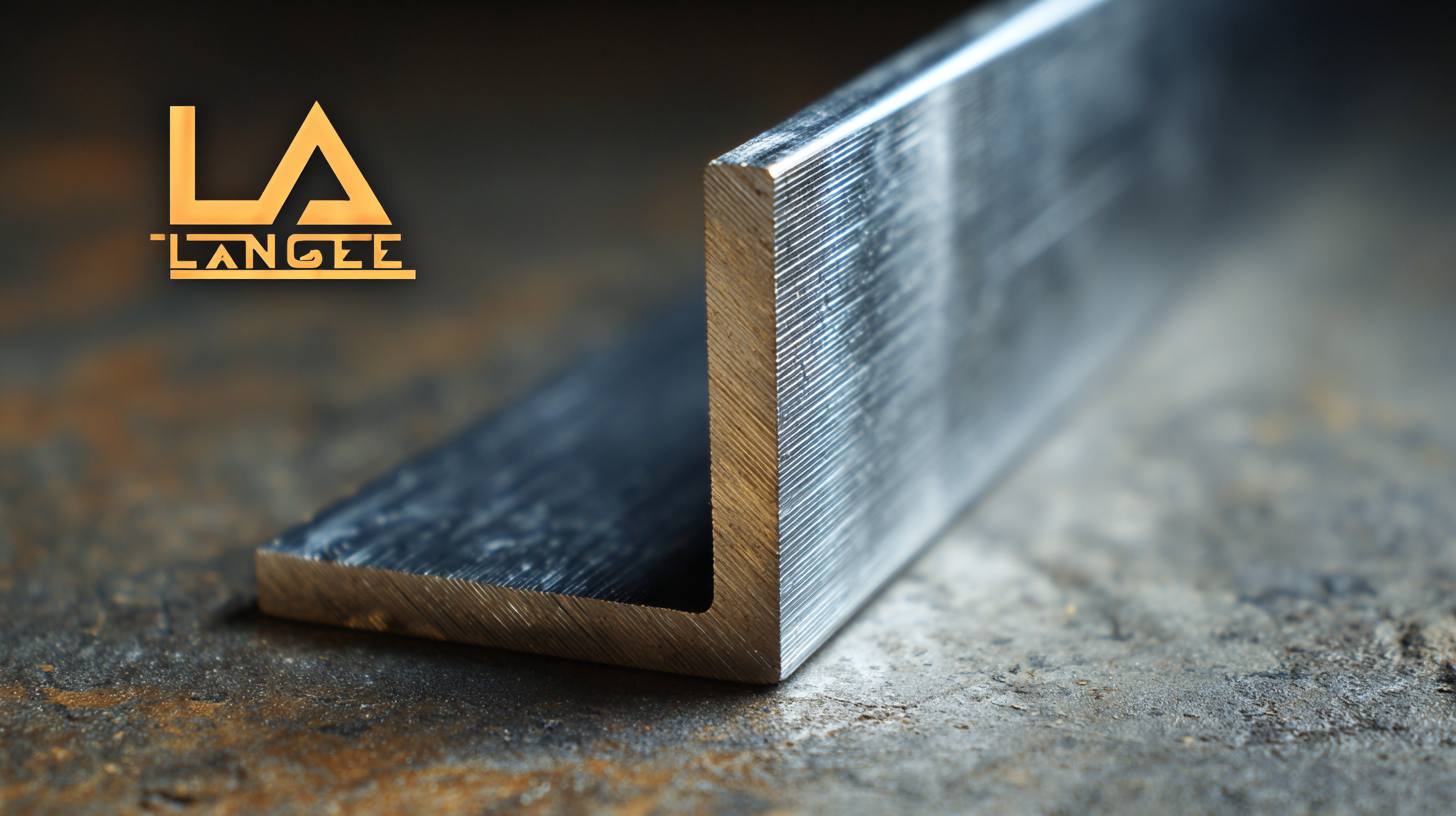

When considering materials for construction and manufacturing, the composition of aluminum plays a crucial role in the structural integrity of L-shaped angle brackets. To meet industry standards, manufacturers often utilize aluminum alloys, such as 6061 and 6063, which provide a balance of strength and ductility. According to the Aluminum Association, the yield strength of 6061 aluminum can exceed 35,000 psi, making it ideal for applications requiring reliable support and durability.

The structural integrity of aluminum also benefits from its resistance to corrosion, particularly when treated with anodization. A report by the American Society of Civil Engineers highlights that anodized aluminum can resist corrosion for over 40 years in urban environments, which significantly extends the lifespan of components used in construction. Selecting the right aluminum composition not only enhances mechanical performance but also ensures that projects remain cost-effective over time, minimizing the need for repairs or replacements. This is why understanding aluminum's properties is essential for anyone involved in design or engineering.

| Reason | Aluminum Type | Strength (MPa) | Corrosion Resistance | Weight (kg/m) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| Lightweight | 6061 | 240 | Excellent | 2.7 | 167 |

| High Strength | 6063 | 210 | Good | 2.7 | 150 |

| Versatility | 7075 | 570 | Moderate | 2.8 | 130 |

| Cost-effectiveness | AL-2024 | 450 | Fair | 2.78 | 120 |

| Easy Fabrication | 5083 | 330 | Very Good | 2.68 | 140 |

When evaluating the best aluminum L shape angles for your next project, understanding the role of manufacturers is crucial. The production process of aluminum components can significantly affect their quality, durability, and overall performance. Manufacturers that adhere to rigorous production standards are more likely to produce angles that can withstand various environmental conditions. Key factors such as extrusion techniques and material sourcing play a vital role in ensuring the aluminum maintains its structural integrity. Engaging with manufacturers who boast advanced production technology can result in a superior product that meets your project requirements precisely.

Certifications are another critical element in assessing manufacturers. Trusted certifications indicate that a manufacturer complies with industry standards and best practices, which often encompass safety, performance, and environmental considerations. For instance, ISO certifications can reassure buyers that the materials produced are consistent and reliable. By prioritizing manufacturers with reputable certifications, you can ensure that the aluminum L shape angles you select not only meet the immediate needs of your project but also contribute to its long-term success.

When it comes to project success, utilizing high-quality materials is vital. Aluminum L shape angles are particularly beneficial due to their versatility and strength. Data from the American Institute of Steel Construction shows that aluminum structures can be lightweight yet exceptionally strong, with a strength-to-weight ratio that surpasses that of steel in some applications. These L shape angles are commonly used in a variety of projects, from residential construction to intricate industrial designs, thanks to their ability to provide stability and support in frameworks, shelves, and supports.

**Tip:** When selecting aluminum L shape angles, always consider the specific load requirements of your project. The right thickness and alloy can significantly impact durability and performance.

In real-world applications, the best aluminum L shape angles are essential for improving overall project efficiency. A report from the Aluminum Association indicates that aluminum's corrosion resistance can increase the lifespan of structural elements, minimizing maintenance costs and downtime. Moreover, these angles can be easily fabricated and customized, offering flexibility in design that can lead to innovative solutions.

**Tip:** Opt for pre-anodized aluminum finishes to enhance aesthetics and protect against environmental wear, ensuring your project stands the test of time while looking great.