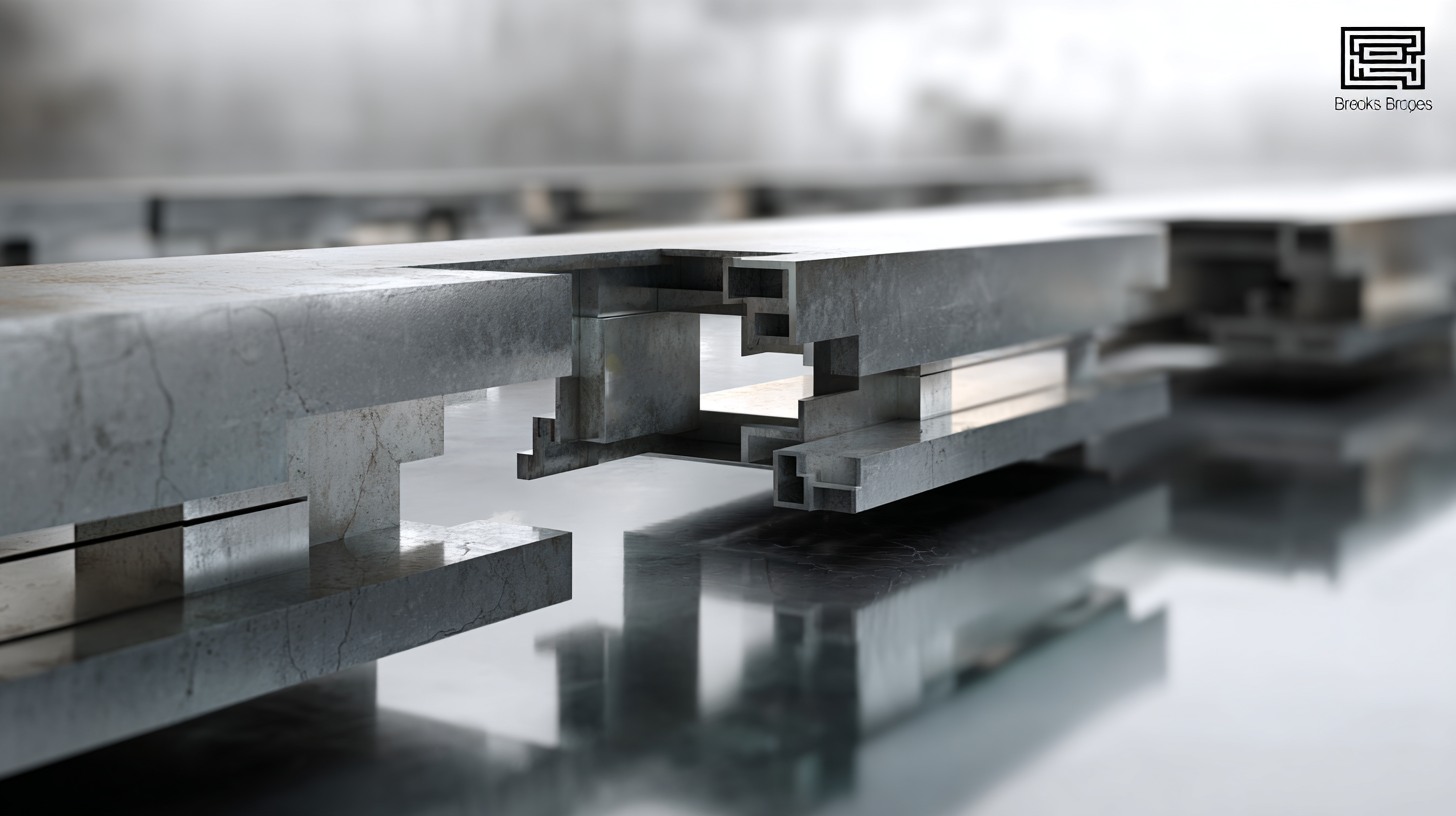

As we navigate through the rapidly evolving landscape of construction and architecture, the significance of Broken Bridge Aluminium Profiles has become increasingly prominent. This innovative solution not only addresses energy efficiency but also enhances aesthetics and durability in building designs. By 2025, industry experts anticipate groundbreaking advancements in technology and design trends that will shape the future of these profiles. From improved thermal insulation to lightweight structures, the evolution of Broken Bridge Aluminium Profiles is set to revolutionize the market. This blog will delve into the key trends and innovations that will define these profiles, providing a comprehensive overview of top strategies that manufacturers and architects can adopt to stay ahead in this competitive field. Join us as we explore the future insights that will drive the development of Broken Bridge Aluminium Profiles into a new era of excellence.

As we look toward 2025, the manufacturing standards for broken bridge aluminium profiles are poised for significant evolution, driven by a combination of innovation and sustainability. An increasing demand for energy-efficient and environmentally friendly building materials will necessitate the adoption of rigorous manufacturing standards. According to industry reports, global aluminium consumption is expected to reach 61 million metric tons by 2025, reflecting a compound annual growth rate of 6.2%. This surge is largely attributed to advancements in recycling technologies and the push for lightweight materials in construction.

In Alabama, major investments, such as the multi-billion dollar aluminium recycling and rolling projects, are indicative of broader trends shaping the market. These projects not only highlight the region's commitment to aluminium production but also emphasize the importance of sustainable practices in manufacturing. Emerging technologies are expected to improve the energy efficiency of aluminium profiles, reducing the overall carbon footprint. As newer standards emerge, manufacturers will need to align with these trends to meet consumer expectations and regulatory requirements while maintaining competitive advantages in a rapidly changing market.

| Trend/Innovation | Description | Projected Impact | Adoption Rate by 2025 |

|---|---|---|---|

| Improved Thermal Insulation | Advancements in insulation materials enhancing energy efficiency. | Reduction in energy costs and increased comfort. | 75% |

| Smart Technology Integration | Incorporation of IoT sensors for monitoring and optimization. | Enhanced building management and maintenance efficiency. | 60% |

| Sustainable Materials | Use of recycled materials and eco-friendly production methods. | Lower environmental impact and improved brand image. | 70% |

| Customizable Designs | Enhanced options for aesthetic and functional custom profiles. | Increased market appeal and user satisfaction. | 65% |

| Lightweight Advanced Alloys | Development of lighter yet stronger aluminum alloys. | Simplified transport and installation processes. | 80% |

The Broken Bridge Aluminium Profile market is poised for significant transformation in the coming years, driven by key innovations that enhance energy efficiency and sustainability. According to a report by MarketsandMarkets, the global market for aluminium profiles is projected to reach $75.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.7%. This growth is attributable to increasing demand for energy-efficient building materials, along with favorable government policies promoting green construction practices.

One of the major innovations in this sector is the development of enhanced thermal insulation technology, which significantly reduces energy loss. Studies indicate that these advanced profiles can improve energy efficiency by up to 40%, making them an attractive option for both residential and commercial applications. Additionally, smart technologies integrated into aluminium profiles, such as sensors for monitoring temperature and humidity, are revolutionizing building management systems. According to Frost & Sullivan, the adoption of smart aluminium solutions is expected to increase by 25% annually by 2025, indicating a clear shift towards more intelligent and sustainable building methodologies.

The aluminium profiles market is currently experiencing significant growth, driven by advancements in technology and an increased demand for lightweight solutions in construction and engineering. Key trends shaping this sector by 2025 include innovations in the manufacturing processes aimed at enhancing strength and durability while reducing environmental impact. Manufacturers are investing in research and development to create profiles that not only meet the stringent requirements of modern architecture but also align with sustainability goals.

As we look towards 2025, analyzing the growth trends of aluminium profiles reveals a shift towards customization and versatility in design. This movement is largely influenced by consumer preferences for personalized solutions in both residential and commercial spaces. Additionally, the rise of green building initiatives is propelling the demand for innovative aluminium profiles that contribute to energy efficiency and reduced carbon footprints. The integration of technology in material production and processing is expected to further accelerate this trend, ensuring that the aluminium profiles of the future are not only functional but also aesthetically appealing and environmentally friendly.

When selecting broken bridge aluminum profiles, it's crucial to consider both performance and durability. The primary factor should be the thermal insulation value, as broken bridge profiles are designed to minimize heat transfer between the interior and exterior. Look for profiles that feature a high-quality thermal break material, which significantly enhances energy efficiency. Additionally, evaluate the aesthetic appeal of the profiles, as they should complement the architecture of the building while providing the necessary functionality.

Maintenance of broken bridge aluminum profiles is equally important to ensure their longevity and performance. Regular cleaning is vital to prevent dirt accumulation, which can lead to corrosion. It's also essential to inspect the seals and gaskets periodically, as worn-out components can compromise insulation. Using non-abrasive cleaning agents helps maintain the finish without damaging the aluminum surface. By following these best practices in selection and maintenance, property owners can maximize the lifespan and effectiveness of their broken bridge aluminum profiles, ultimately leading to a more sustainable and energy-efficient living environment.

The production of aluminium profiles is entering a transformative phase as we approach 2025. One of the primary challenges facing manufacturers is the rising demand for sustainability. Consumers and industries are increasingly seeking eco-friendly products, pushing aluminium producers to adopt greener practices. This includes using recycled materials and implementing energy-efficient manufacturing processes. As companies strive to reduce their carbon footprint, innovations in recycling technology will become crucial, enabling higher quality output and minimizing waste throughout the production cycle.

Another significant challenge is the integration of advanced technologies into aluminium profile manufacturing. The rapid evolution of Industry 4.0 is creating opportunities for greater automation and digitalization. Companies will need to balance investment in smart technologies, such as IoT-enabled machinery and AI-driven analytics, with the potential retraining of their workforce. Emphasizing employee skill development will ensure that businesses can adapt to these technological advancements while preserving operational efficiency. Collaborative efforts between tech developers and aluminium manufacturers will be essential to navigate these innovations effectively, ultimately driving the industry toward a more efficient and sustainable future.