In the dynamic landscape of the construction and manufacturing industries, the demand for efficient Heat Insulation Aluminum Profiles has surged in response to increasing global focus on energy conservation and sustainability. According to a recent report by MarketsandMarkets, the global aluminum profile market is expected to grow from USD 76.68 billion in 2021 to USD 113.82 billion by 2026, driven largely by the rising adoption of energy-efficient building materials. This wave of growth presents a significant opportunity for manufacturers to innovate and meet the stringent certification standards required in various markets. As China positions itself as a leader in quality manufacturing and exportation, it becomes imperative to explore how the integration of advanced technologies in Heat Insulation Aluminum Profile production can unlock new avenues for success and establish a competitive edge in the increasingly international marketplace.

In modern construction, heat insulation has become a pivotal factor influencing building design and energy efficiency. Aluminum profiles, widely used in structural frameworks and facades, now prioritize thermal insulation to meet increasing energy standards. Incorporating advanced heat insulation technology not only enhances the comfort of living spaces but also significantly reduces energy consumption, making buildings more sustainable.

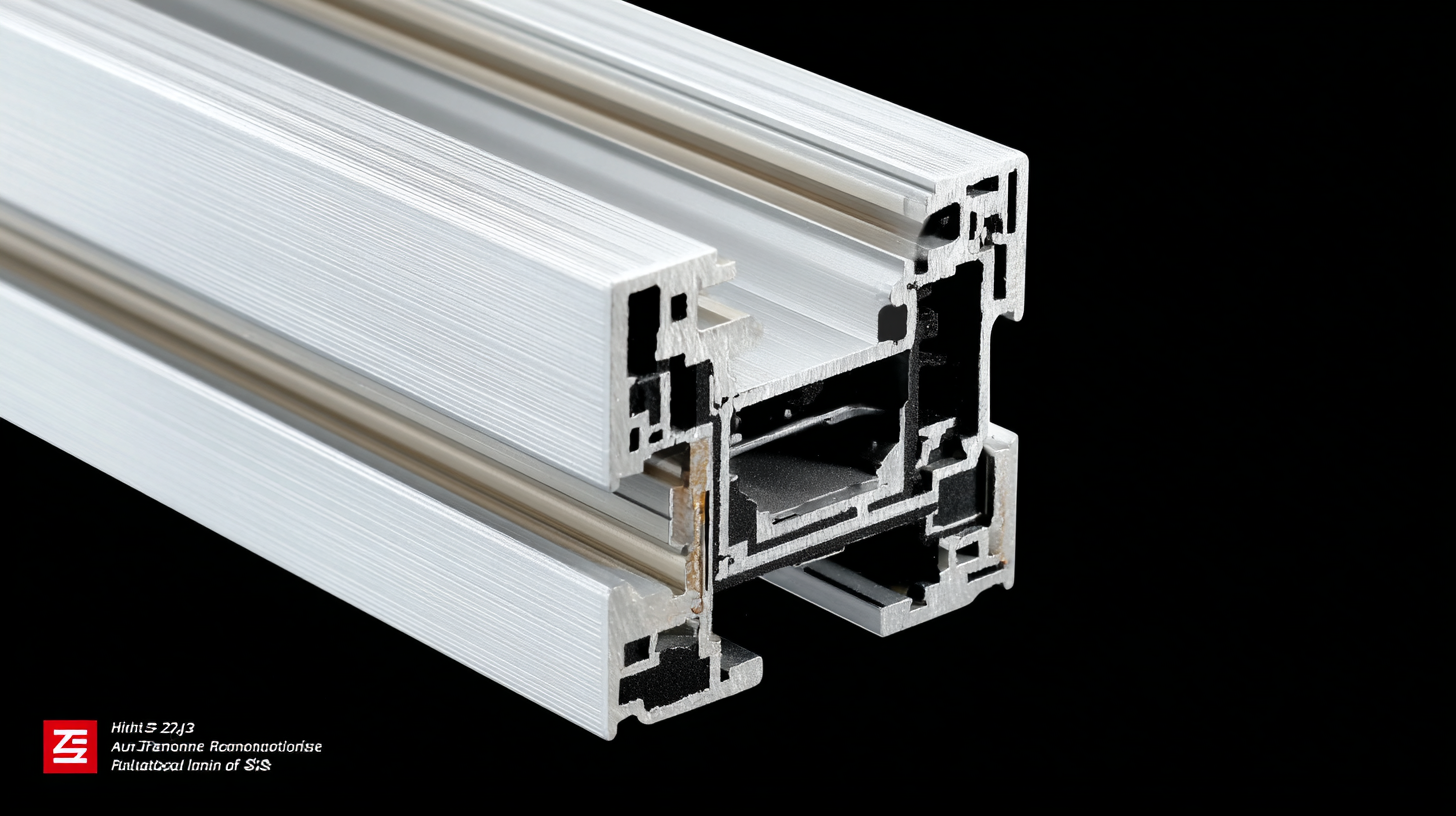

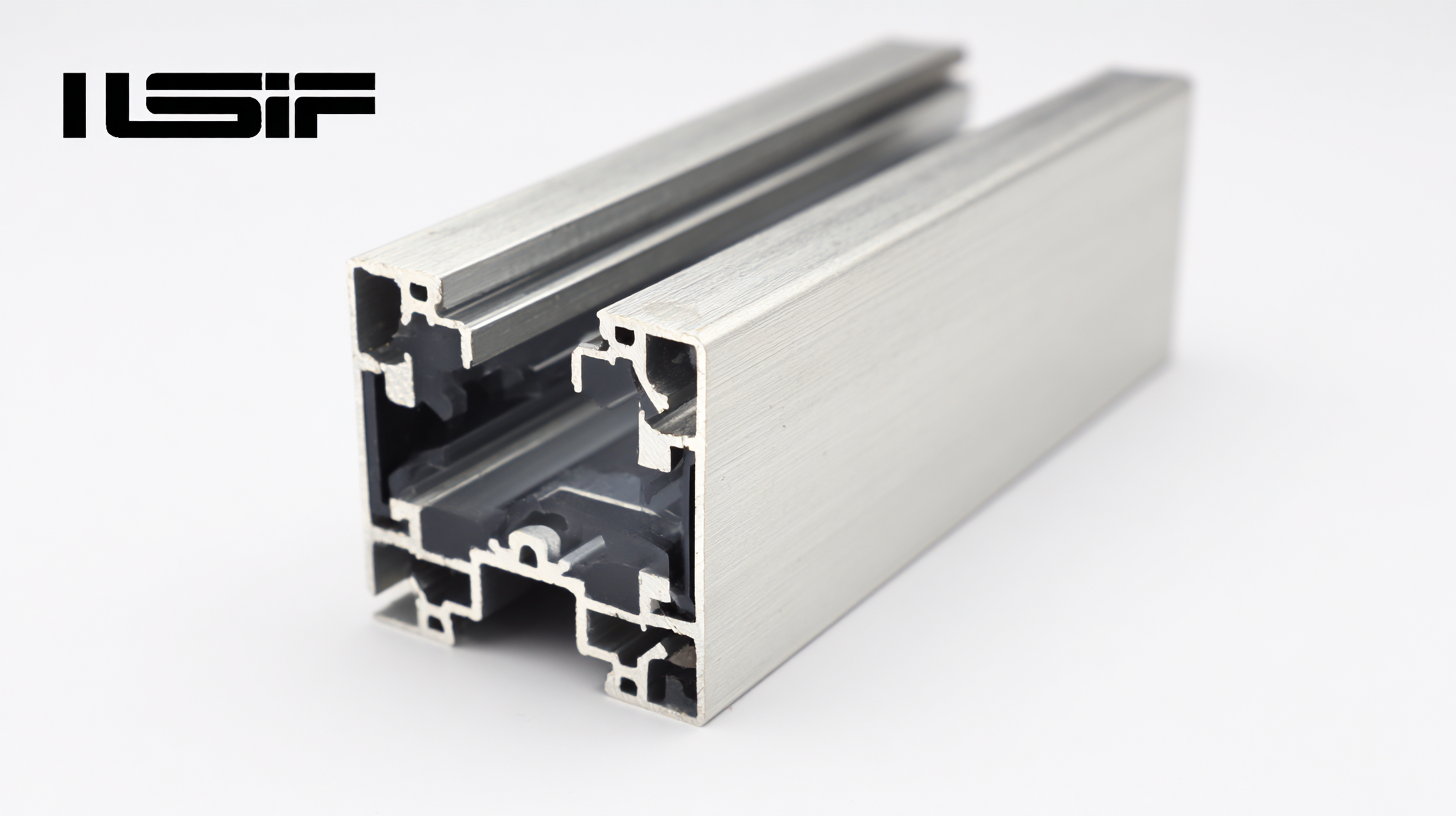

The importance of heat insulation in aluminum profiles cannot be overstated. With the rising costs of energy and growing environmental concerns, architects and builders are seeking innovative solutions to optimize thermal performance. The use of thermally broken aluminum profiles, which feature an insulating material between the inner and outer sections, provides an effective barrier against thermal bridging. This technology ensures that buildings maintain stable indoor temperatures, ultimately leading to reduced heating and cooling costs.

Moreover, obtaining the right certifications for heat insulation products enhances their marketability. Compliance with global standards showcases a commitment to quality and sustainability, attracting environmentally conscious consumers and investors. As the demand for energy-efficient construction materials continues to escalate, understanding and implementing heat insulation in aluminum profiles will be essential for success in the competitive global market.

This chart illustrates the thermal conductivity (W/m²K) of various aluminum profiles used in modern construction, highlighting the importance of heat insulation in optimizing energy efficiency.

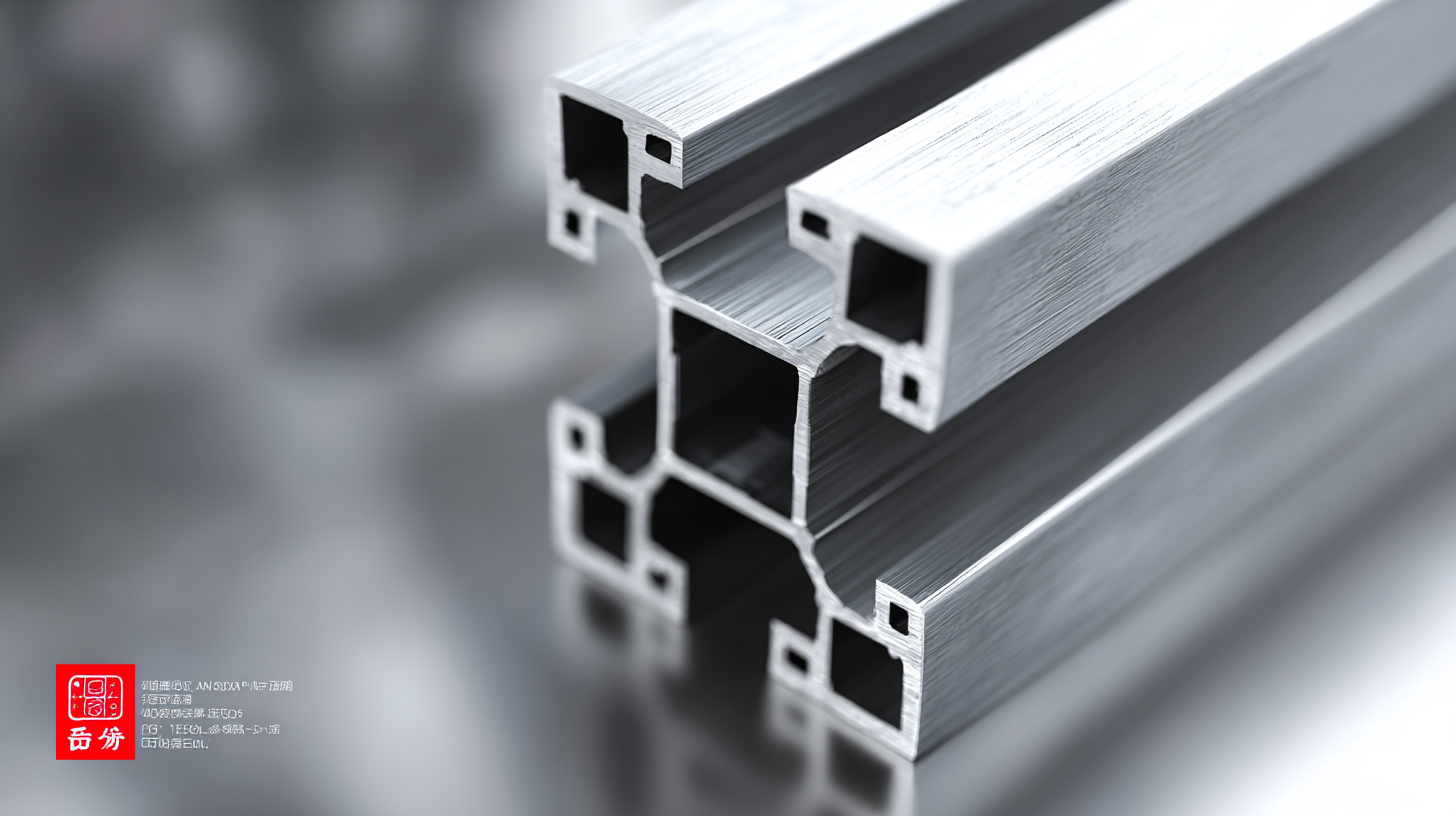

When it comes to enhancing energy efficiency, the role of heat insulation aluminum profiles cannot be overstated. These profiles have been engineered to offer superior thermal insulation, crucial in both residential and commercial applications. High-performance heat insulation aluminum profiles utilize innovative design features and advanced materials, ensuring optimal resistance to heat transfer. Key technical parameters such as thermal conductivity, density, and mechanical strength play a vital role in determining their effectiveness. For instance, profiles that boast a lower thermal conductivity are more capable of minimizing heat loss, making them essential in energy-conscious construction.

Moreover, the certification data associated with these aluminum profiles is fundamental for compliance with global market standards. Certifications indicate that products fulfill specific performance criteria and safety measures, which can significantly influence consumer trust and marketability. When evaluating these profiles, considering their technical specifications alongside relevant certifications is crucial for making informed decisions. As the demand for sustainable building solutions grows, understanding these parameters will enable stakeholders to select the most effective heat insulation solutions while adhering to environmental standards.

The global market for insulation solutions is experiencing significant growth, driven by an increasing demand for efficient thermal management across various industries. The gas-insulated switchgear market is projected to expand from approximately $23.094 billion in 2024 to an impressive $36.878 billion by 2032. This surge reflects a wider trend in infrastructure development and energy efficiency mandates worldwide, prompting manufacturers to seek advanced insulation materials.

Additionally, the extruded polystyrene (XPS) panel market is expected to see its valuation rise to $854 million in 2024, with further growth anticipated as the sector adapts to rising environmental standards and innovative construction practices. This high-performance insulation material is favored for its durability and energy-saving properties, making it essential for both residential and commercial applications, aligning with the broader trend of sustainable building solutions. By 2033, industries focusing on insulation under corrosion and spray insulation coatings are also set to benefit, as the demand for protective materials continues to climb in response to the evolving regulatory landscape and energy efficiency requirements.

In the insulation industry, certification standards are critical for ensuring the efficacy and safety of aluminum profiles used in construction and manufacturing. Reports indicate that high-performance aluminum profiles must adhere to various international certification standards, such as ISO 9001 for quality management and EN 15088 for recycling and sustainability. According to a recent market analysis published by the Global Insulation Association, 78% of industry leaders highlighted that compliance with these standards directly correlates with customer satisfaction and long-term partnerships.

Moreover, the implementation of thermal performance certifications, such as the European Thermal Performance of Building Elements (EtICS), has gained increasing attention. Data from the Aluminum Association reveals that profiles meeting specific thermal insulation criteria can enhance energy efficiency by up to 30%. This not only meets the growing demand for sustainable building solutions but also positions manufacturers as leaders in a rapidly changing global market. As stakeholders look for reliable products, adherence to these rigorous certification standards becomes imperative for companies aiming to secure their competitive edge.

When selecting the right type of heat insulation aluminum profile for your project needs, it’s essential to consider the

thermodynamic performance,

structural integrity, and application-specific requirements. Different profiles possess varied insulation properties,

which can significantly influence energy efficiency in architectural and industrial applications.

For instance, if you're targeting a commercial building that requires stringent temperature control, opting for profiles with higher thermal resistance and low thermal conductivity will yield better results.

Additionally, it's crucial to factor in the environmental conditions and aesthetic preferences in your selection process. The global market offers a diverse range of aluminum profiles designed to meet both functionality and style.

Choosing profiles that are not only effective in heat insulation but also compliant with certification standards, such as LEED or ENERGY STAR, can enhance your project's sustainability credentials.

Engaging with trusted suppliers who provide up-to-date certification data will ensure that your chosen profiles meet international standards, ultimately contributing to the success and longevity of your project.