Polyurethane pouring for aluminum profile applications has gained significant attention in recent years. Industry expert Dr. Emily Zhang, a chemical engineer specializing in polyurethane systems, once stated, "The right polyurethane solution can revolutionize aluminum profile applications." Her insights highlight the importance of selecting appropriate materials for optimal performance.

The process of polyurethane pouring aluminum profiles can be complex yet rewarding. Correct formulations ensure durability and resistance to environmental factors. Each application requires tailored approaches, demanding careful consideration of specific requirements. Many companies still overlook the nuances in this specialized field.

Despite advancements, challenges persist. Some manufacturers struggle with consistency and quality control. Innovations in polyurethane chemistry continue, but issues arise when adapting to unique aluminum profiles. This ongoing journey necessitates continuous improvement and critical thinking in material science.

Polyurethane pouring has become a significant method in aluminum profile applications. This technique offers exceptional durability and flexibility. According to recent industry reports, polyurethane provides up to 1,500 psi of tensile strength. This strength is critical in various applications, ensuring that aluminum profiles can withstand mechanical stresses during use.

One aspect that merits attention is the curing time of polyurethane. While conventional polyurethane can take anywhere from 24 to 48 hours to cure fully, rapid-setting formulations are available. However, these faster options might not offer the same mechanical properties. Adapting to specific project timelines can be challenging and requires careful consideration.

Another element is the complexity of the pouring process. Maintaining an even pour can be difficult. This inconsistency can lead to weak spots or bubbles in the final product, reducing overall quality. Statistics show that improper pouring techniques can reduce strength by up to 30%. Investing in training or employing skilled technicians can mitigate these risks and improve the results.

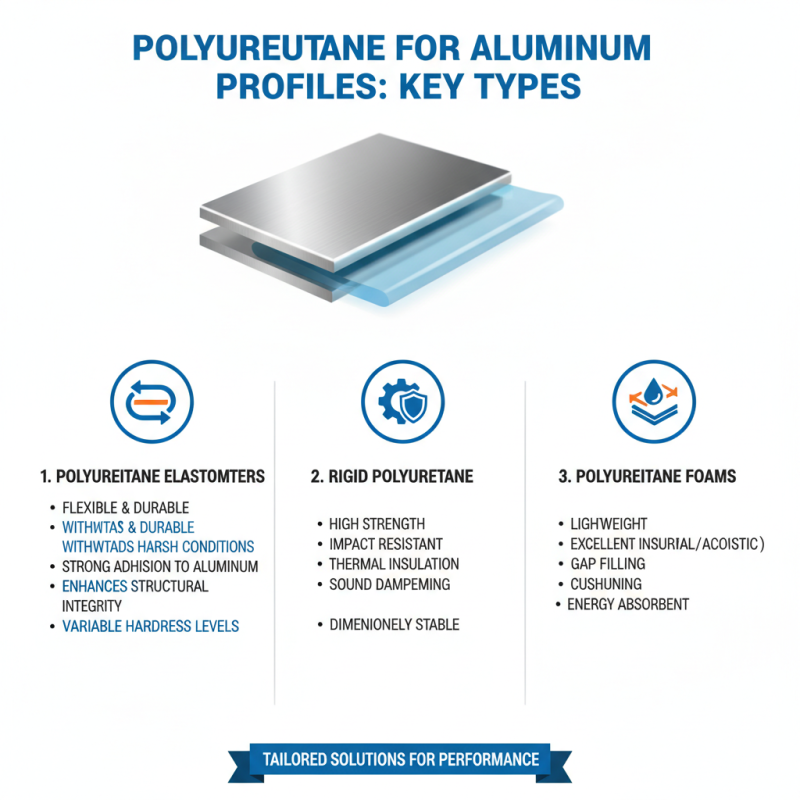

When selecting polyurethane materials for aluminum profiles, several key types stand out. Polyurethane elastomers are popular due to their flexibility and durability. These materials can withstand harsh conditions. They adhere well to aluminum, which enhances structural integrity. The variety of hardness levels allows for tailored applications.

Thermoplastic polyurethanes (TPUs) offer another option. They are easy to process and customize. Their impact resistance is impressive. However, TPUs can sometimes be prone to environmental stress cracking. This is an important consideration. Users must test material compatibility with their specific aluminum profiles.

Casting resins made from polyurethane are also effective. They can create complex shapes with precision. However, curing times can vary. This may affect production schedules. It's crucial to monitor the process closely. Overall, understanding the strengths and weaknesses of each polyurethane type is essential for achieving optimal results in aluminum profile applications.

Polyurethane is a versatile material that offers significant benefits for aluminum profile applications. Its lightweight nature makes it ideal for reducing the overall weight of structures. When poured into molds, polyurethane forms a strong bond with aluminum. This enhances the durability of the profiles, reducing wear and tear. The flexibility of polyurethane also allows it to absorb shocks, protecting aluminum from potential damage.

Additionally, polyurethane has excellent resistance to various environmental factors. It can withstand moisture, chemicals, and UV exposure. This property ensures that aluminum profiles maintain their integrity over time. Using polyurethane can also improve the aesthetic appeal of finished products. It provides a smooth, uniform finish that enhances the overall look of aluminum applications.

However, there are challenges in its application. Mixing and pouring require precision for the best results. If not done correctly, inconsistencies can arise. The curing time can also be a concern, as it varies with temperature and humidity. These factors demand careful planning and execution. For optimal performance, it's crucial to highlight the importance of quality control throughout the process.

Pouring polyurethane into aluminum profiles requires careful planning and execution. Start by selecting the right type of polyurethane for your application. Consider the hardness and flexibility needed. The mix ratio must be precise; even slight variations can affect the final product.

Before pouring, ensure that the aluminum surfaces are clean and dry. Dust and debris can lead to poor adhesion. Apply a suitable release agent to facilitate easy demolding. Pouring at the right temperature is vital. Cooler temperatures can increase viscosity, making it challenging to fill the profiles completely.

Monitor your pouring technique. A steady hand helps avoid bubbles, which can compromise strength. Once poured, watch for long curing times. Patience is necessary; rushing can lead to uneven results. The curing environment should remain consistent in temperature and humidity. Remember, trial and error is part of the process. Learning from imperfections leads to better techniques in future projects.

Polyurethane pouring is pivotal in aluminum profile applications. However, challenges arise that can affect the quality of the outcome. A recent report indicated that 40% of manufacturers face issues with adhesion and air bubbles during the pouring process. These challenges can compromise the final product's integrity and performance.

One common problem is improper surface preparation. A survey found that 30% of failures in polyurethane applications stem from inadequate cleaning and treatment of aluminum profiles. This leads to poor bonding. Furthermore, air entrapment can occur due to incorrect pouring techniques. This often results in aesthetic and mechanical defects. Ensuring meticulous preparation and employing proper pouring methods can mitigate these issues significantly.

Another significant challenge is temperature control during curing. Studies show that variations in temperature can alter properties of the polyurethane material. Ideal temperatures should be maintained to ensure optimal material performance. Failure to monitor this can lead to inconsistent results. Adjustments to the pouring environment may be necessary to achieve desired outcomes, reflecting a need for continuous improvement in practices.