As the global demand for energy-efficient building materials continues to rise, the importance of Thermal Break Aluminium Profiles has become increasingly evident in construction and manufacturing sectors. According to a recent report by the International Energy Agency, buildings account for approximately 40% of global energy consumption, underscoring the necessity for innovative materials that enhance insulation and reduce energy loss.

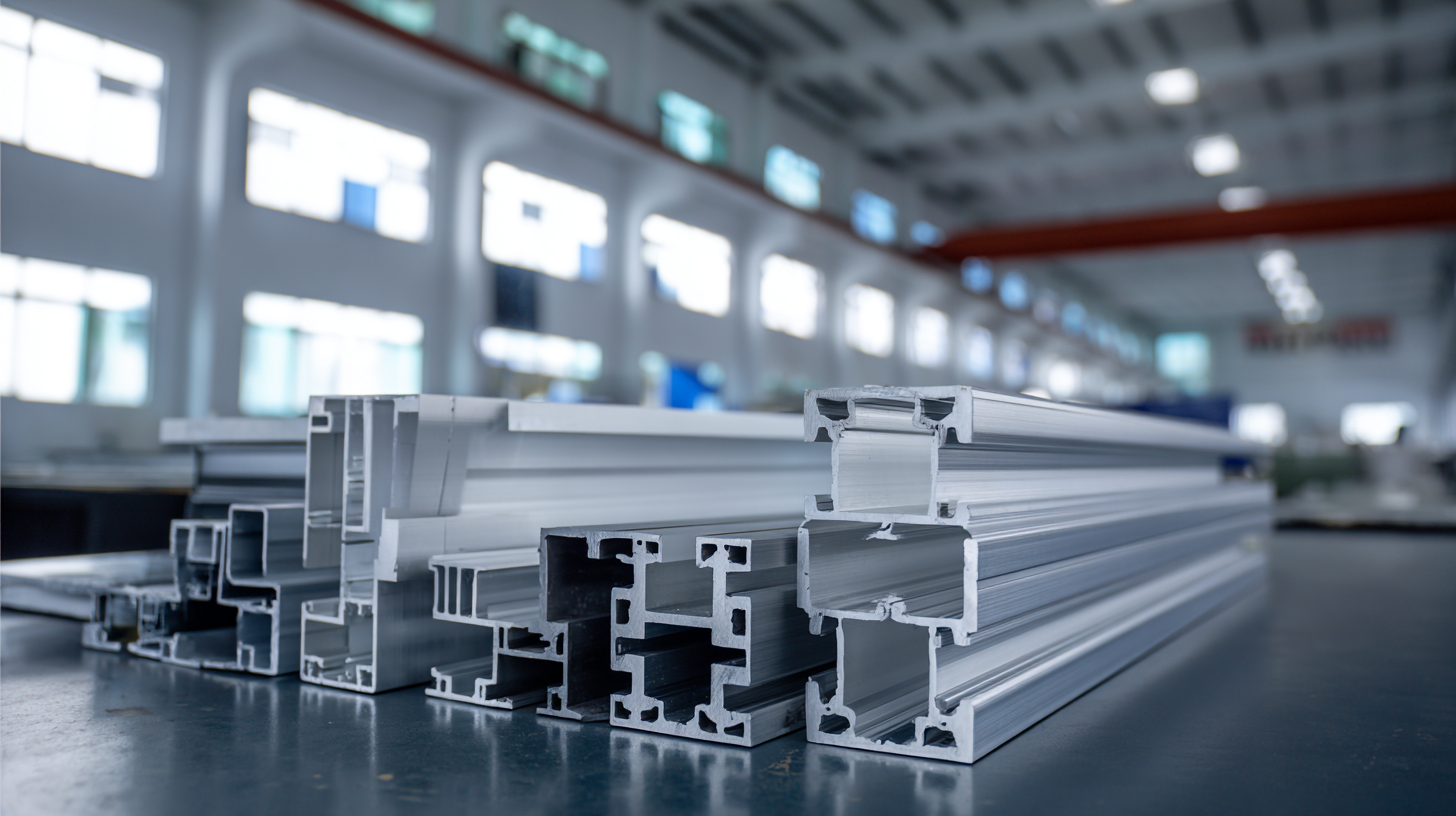

China's position as a leading manufacturer of high-quality Thermal Break Aluminium Profiles has enabled it to cater to a burgeoning international market, with exports witnessing a year-on-year increase of 15% over the past few years. With a commitment to quality assurance and advanced production techniques, Chinese manufacturers are setting new standards in the industry, ensuring that these profiles not only meet but exceed global performance benchmarks. As the market seeks sustainable solutions, China's prowess in thermal break technology presents a viable pathway towards achieving energy-efficient construction worldwide.

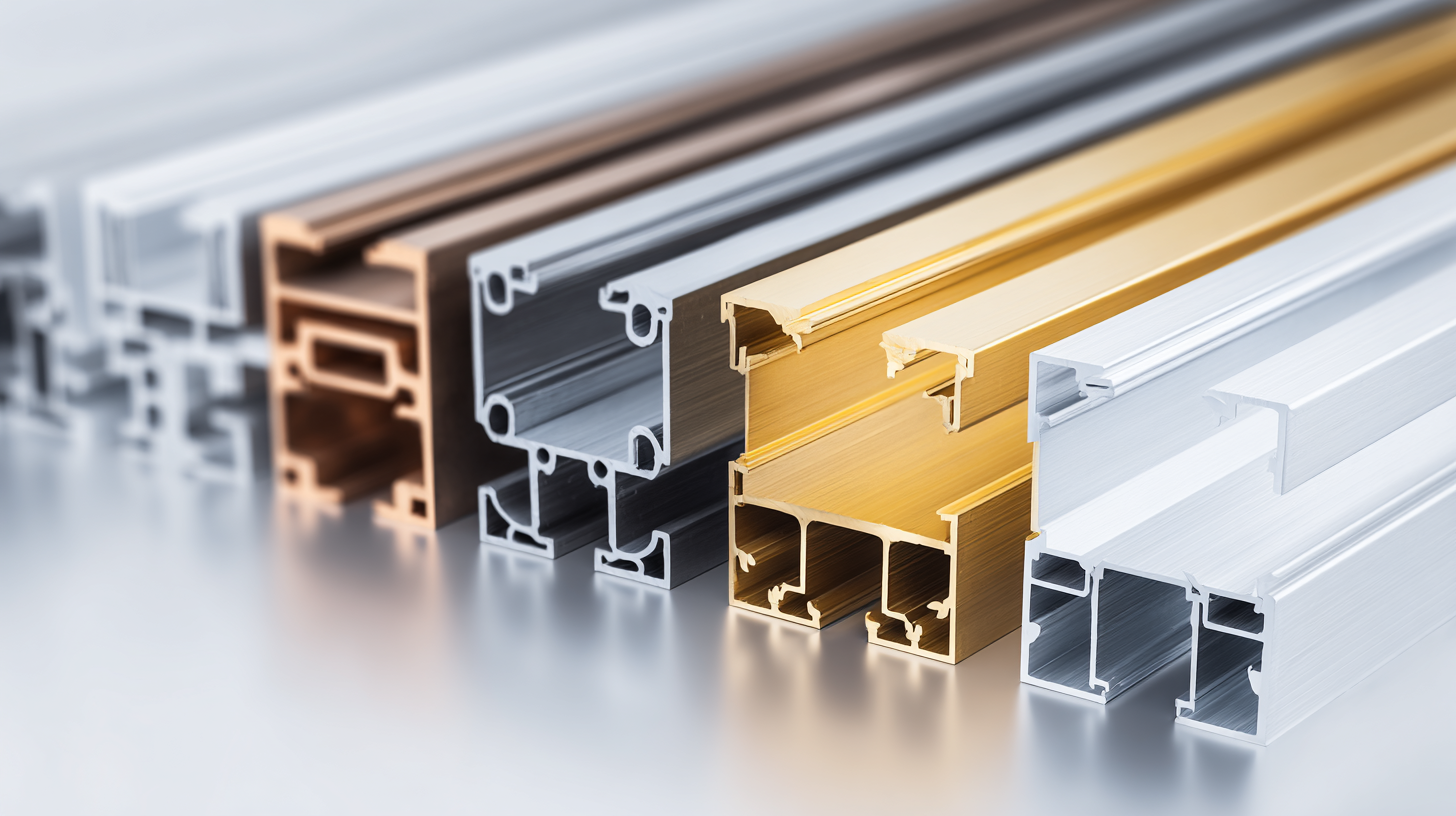

As the demand for energy-efficient building materials continues to rise, thermal break aluminium profiles are gaining significant popularity in export markets. These profiles provide superior insulation properties, helping to reduce energy costs and enhance the comfort of residential and commercial spaces. Key trends include the integration of advanced manufacturing techniques, which not only enhance the performance of thermal break profiles but also allow for custom designs tailored to specific market needs.

Tip: When considering thermal break aluminium profiles for export, focus on the thermal performance ratings and certifications of the products. This ensures compliance with international standards and builds trust with potential buyers.

Another emerging trend is the increasing emphasis on sustainability. Manufacturers are exploring eco-friendly practices, from sourcing recyclable materials to minimizing waste during production. This not only appeals to environmentally conscious consumers but also supports global initiatives to reduce carbon footprints.

Tip: It's crucial to highlight the sustainable features of your products in marketing materials. Showcase certifications or eco-labels that demonstrate the environmental benefits of using thermal break aluminium profiles.

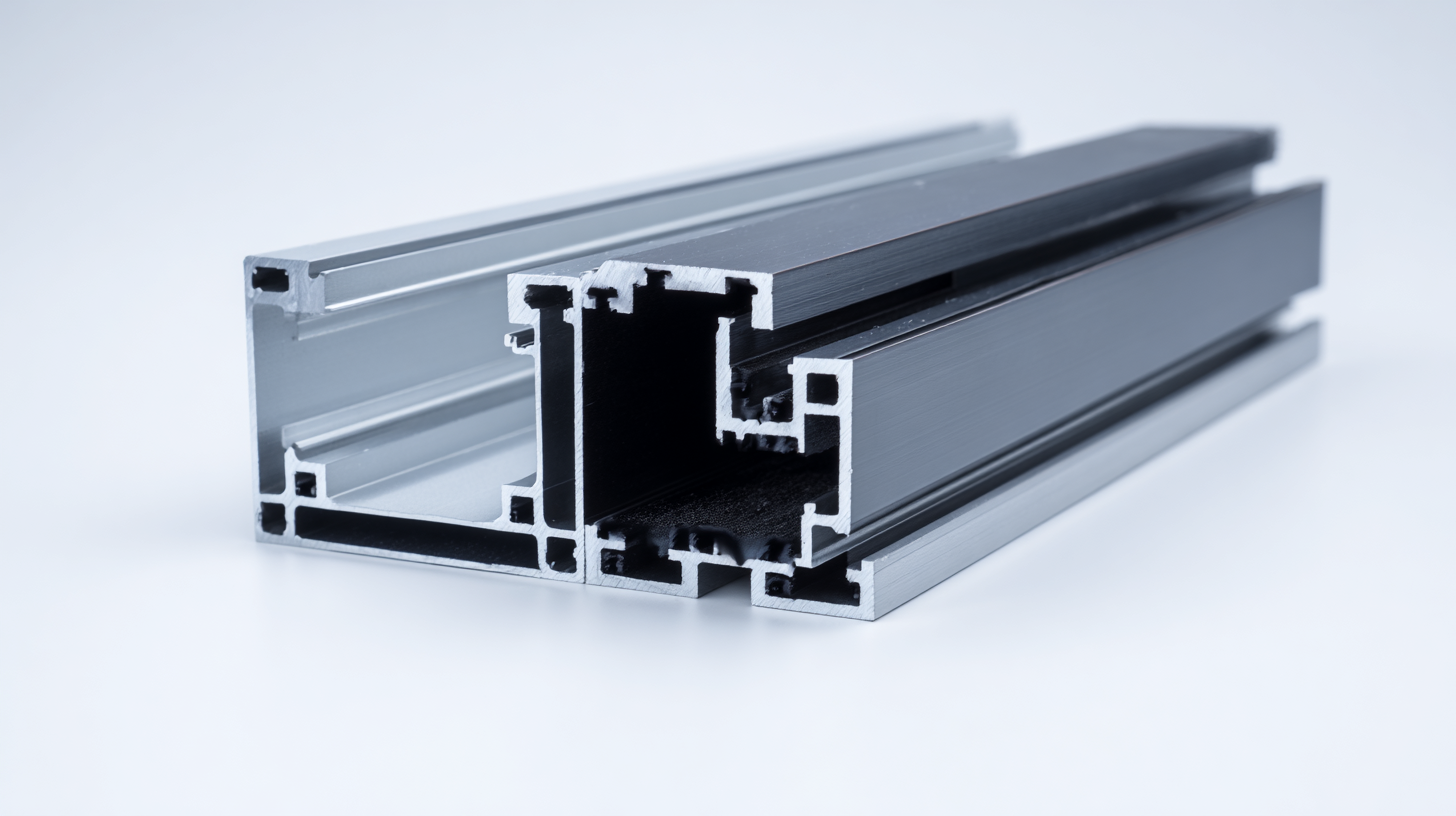

Thermal break technology in aluminium manufacturing offers a significant advantage in energy efficiency and building performance. By incorporating materials that reduce heat transfer, thermal break profiles help maintain indoor temperatures, thus reducing heating and cooling costs. A study by the Department of Energy highlights that buildings utilizing thermal break technology can see energy savings of up to 30%. This not only contributes to lower utility bills but also minimizes the carbon footprint, aligning with global sustainability goals.

For manufacturers and builders, the use of thermal break aluminium profiles is increasingly seen as a necessity rather than an option. Notably, the enhanced insulation properties lead to improved thermal comfort for occupants, which is crucial in high-performance buildings. Moreover, as per a recent market analysis, the demand for thermal break aluminum profiles is forecasted to grow by 8.5% annually, indicating a strong trend towards energy-efficient construction.

Tip: When selecting thermal break aluminium profiles, ensure that they meet the latest building codes for energy efficiency. Look for profiles that have been tested for performance by recognized entities to guarantee their effectiveness in insulation. Additionally, consider the aesthetic options available to maintain the design integrity of your building while benefiting from superior energy performance.

In recent years, the demand for sustainable building materials has surged, and thermal break aluminium profiles are at the forefront of this movement. These profiles not only enhance energy efficiency in modern architecture but are also produced through environmentally friendly processes. Leading factories in China have adopted innovative techniques to minimize waste and reduce their carbon footprint, making them key players in the global export market.

Utilizing recyclable materials is a cornerstone of sustainable practices in the production of thermal break aluminium profiles. Many manufacturers have implemented closed-loop systems, where scrap aluminium is collected and remelted for reuse in new products. This not only conserves resources but also significantly lowers energy consumption compared to using virgin materials. Additionally, factories are increasingly investing in renewable energy sources, such as solar and wind, to power their operations, further emphasizing their commitment to sustainability.

Moreover, advancements in technology have enabled the creation of high-performance thermal break aluminium profiles that meet strict environmental standards. These profiles help enhance insulation, reducing reliance on heating and cooling systems in buildings. By integrating sustainable manufacturing practices, leading Chinese factories are not just meeting current market needs but are also paving the way for a greener future in construction and architecture worldwide.

| Profile Type | Thermal Conductivity (W/m·K) | Recyclability (%) | Production Year | Certifications |

|---|---|---|---|---|

| Aluminium Profile A | 1.2 | 90 | 2023 | ISO 14001, CE |

| Aluminium Profile B | 1.1 | 85 | 2022 | ISO 50001, LEED |

| Aluminium Profile C | 1.0 | 92 | 2023 | Energy Star, REACH |

| Aluminium Profile D | 1.3 | 88 | 2021 | BREEAM, FSC |

In the realm of thermal break aluminium profiles, innovative design approaches are crucial for enhancing thermal performance. With the increasing demand for energy-efficient building materials, manufacturers are focusing on the integration of advanced technologies to improve the insulating properties of aluminium profiles. According to a report by the International Energy Agency, buildings are responsible for nearly 40% of global energy consumption, and enhancing thermal performance can significantly reduce heating and cooling costs.

Recent advancements in thermal break designs include the use of high-performance polyamide strips that offer superior insulation capabilities. These materials not only prevent thermal bridging but also maintain optimal strength and durability. A study from the Aluminum Association revealed that well-designed thermal break profiles can lead to a reduction in energy loss by up to 45%, emphasizing the importance of innovative approaches in this sector. As manufacturers in China lead the way in developing these cutting-edge profiles, their commitment to sustainability and energy efficiency is set to reshape the global market.

Effective global distribution of thermal break aluminium profiles is crucial for companies aiming to succeed in the competitive market. According to a recent report by Grand View Research, the global aluminium market is projected to reach over $250 billion by 2025, with demand increasing across various sectors such as construction and automotive. This trend highlights the need for manufacturers to establish robust distribution strategies that ensure their products reach international markets efficiently.

Effective global distribution of thermal break aluminium profiles is crucial for companies aiming to succeed in the competitive market. According to a recent report by Grand View Research, the global aluminium market is projected to reach over $250 billion by 2025, with demand increasing across various sectors such as construction and automotive. This trend highlights the need for manufacturers to establish robust distribution strategies that ensure their products reach international markets efficiently.

One key strategy involves leveraging technological advancements in logistics and supply chain management. By adopting smart logistics solutions, companies can streamline their distribution processes, minimize delays, and reduce costs. Additionally, forming strategic partnerships with local distributors can enhance market penetration and provide valuable insights into regional customer preferences. A report from Mordor Intelligence indicates that effective partnerships can increase market reach by 30% in emerging markets, making it essential for manufacturers to cultivate strong relationships worldwide.

Furthermore, sustainability is becoming a significant factor influencing global distribution strategies. Research from the International Aluminium Institute shows that aluminium recycling plays a vital role in reducing carbon footprints, with over 75% of aluminium ever produced still in use today. By promoting the eco-friendly aspects of their products, manufacturers not only cater to environmentally conscious consumers but also comply with increasingly stringent global regulations, thereby gaining a competitive edge in the marketplace.