The future of Aluminum Handle Extrusions is poised for substantial growth as the demand for lightweight, durable materials intensifies across various industries, including automotive, consumer goods, and construction. According to a recent report by ResearchAndMarkets, the global aluminum extrusion market is expected to reach $63.78 billion by 2026, growing at a CAGR of 6.1%. This growth is driven by the increasing preference for aluminum over traditional materials due to its excellent strength-to-weight ratio, corrosion resistance, and adaptability in design.

However, manufacturers face common challenges in producing high-quality Aluminum Handle Extrusions, such as maintaining precise tolerances, minimizing surface defects, and optimizing production processes. Addressing these challenges is crucial for manufacturers to enhance product quality and meet the rising market demands, ensuring a competitive edge in the manufacturing landscape.

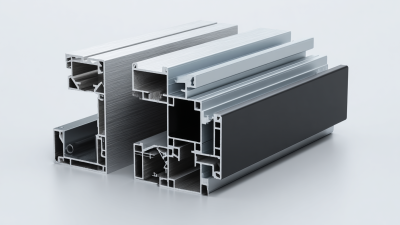

Aluminum handle extrusions play a crucial role in various industries, yet manufacturers often face a plethora of challenges during the process. One of the most prevalent issues is the dimensional accuracy of the extruded profiles. According to a study by the Aluminum Association, nearly 30% of extrusions fail to meet the stringent tolerances required for high-performance applications. This can lead to increased scrap rates and additional costs, as manufacturers must frequently rework or replace defective products.

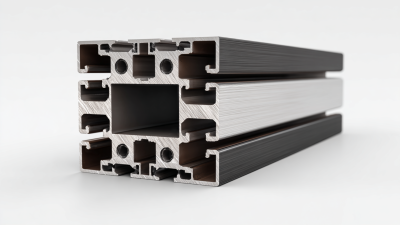

Another significant challenge in aluminum handle extrusions is die design and maintenance. Poorly designed dies can result in uneven flow and inconsistencies in wall thickness, impacting both the performance and aesthetic quality of the final product. The Extrusion Technology and Applications Group (ETAG) reports that optimizing die design can reduce overall production costs by up to 15%, emphasizing the importance of investing in advanced design technologies and regular die maintenance to improve extrusion quality and efficiency.

Moreover, aluminum alloy selection plays a vital role in the success of handle extrusions. A failure to choose the appropriate alloy can lead to issues such as corrosion and mechanical weakness. The International Aluminum Institute reports that selecting the right alloy not only enhances performance but can also improve the lifecycle of the product, offering manufacturers a competitive edge in the marketplace. Understanding these challenges and leveraging data-driven insights is essential for aluminum handle extrusion manufacturers aiming to optimize their production processes.

Aluminum extrusion manufacturers face significant challenges, particularly in maintaining stringent quality control measures throughout the production process. One critical focus is the monitoring of zone temperatures and melting temperatures during extrusion. Accurate temperature control ensures that the aluminum maintains its desired properties and minimizes defects, such as warping or inadequate bonding. With advancements in technology, the industry increasingly utilizes terahertz radiation for contact-free thickness measurements, which allows for real-time monitoring without damaging the materials. This technology is proving essential in sectors ranging from aerospace to pharmaceuticals, where precision is paramount.

Another essential aspect of quality control is the development of innovative measurement systems designed to analyze aluminum quality in real-time. Researchers are exploring ways to detect imperfections as they occur, thereby reducing scrap rates and improving overall efficiency in the production process. By integrating advanced in-process monitoring strategies that evaluate force, geometry, and temperature, manufacturers can ensure a consistent product quality and respond promptly to any deviations. This multi-faceted approach to quality control not only enhances the integrity of aluminum extrusions but also aligns with the industry's goals for sustainable and optimized production practices.

| Challenge | Impact | Quality Control Measure | Solution |

|---|---|---|---|

| Dimensional Inaccuracy | Reduced product fit and assembly issues | Regular Calibrations | Implement precision measuring tools and calibration schedules |

| Surface Defects | Aesthetic issues and reduced corrosion resistance | Visual Inspections | Conduct routine visual and surface quality inspections |

| Inconsistent Mechanical Properties | Compromised product strength and durability | Material Testing | Perform regular tensile and hardness tests on samples |

| Sustainable Manufacturing Practices | Environmental impact and regulatory compliance issues | Waste Management Protocols | Establish recycling practices and waste reduction plans |

| Inadequate Heat Treatment | Reduced design flexibility and potential for failure | Controlled Heating Processes | Monitor and adjust heat treatment parameters regularly |

Optimizing the design of aluminum handle extrusions is crucial for enhancing efficiency and reducing production costs. One of the primary challenges manufacturers face is ensuring the extrusion process accommodates variations in design specifications. Streamlined design not only minimizes material waste but also improves the structural integrity of the final product. By leveraging advanced simulation tools and design software, manufacturers can test different profiles and geometries virtually, allowing for quick adjustments before the actual production begins.

Optimizing the design of aluminum handle extrusions is crucial for enhancing efficiency and reducing production costs. One of the primary challenges manufacturers face is ensuring the extrusion process accommodates variations in design specifications. Streamlined design not only minimizes material waste but also improves the structural integrity of the final product. By leveraging advanced simulation tools and design software, manufacturers can test different profiles and geometries virtually, allowing for quick adjustments before the actual production begins.

Another key aspect of optimizing aluminum handle extrusion design is the selection of appropriate alloy. The right alloy offers a balance between strength, weight, and machinability, which can significantly impact the extrusion process. Moreover, considering the end-use environment of the handles can guide manufacturers in choosing finishes that enhance durability and aesthetic appeal. By focusing on these design factors, manufacturers can overcome common challenges associated with aluminum handle extrusions and achieve higher levels of efficiency and quality in their products.

Reducing waste in aluminum handle production is a critical goal for manufacturers striving to enhance efficiency and sustainability. One of the most effective practices involves optimizing the extrusion process. By carefully calibrating parameters such as temperature, pressure, and die design, manufacturers can minimize scrap material generated during production. Implementing real-time monitoring systems can further aid in identifying and correcting inefficiencies, ensuring that every ounce of material is utilized effectively.

Additionally, adopting a closed-loop recycling system can significantly contribute to waste reduction. Manufacturers should focus on collecting and reprocessing the scrap material generated during the extrusion process. This not only conserves resources but also reduces the environmental impact associated with aluminum production. Training employees on best practices for handling and recycling scrap materials can foster a culture of sustainability within the workplace, ultimately leading to improved production outcomes and reduced operational costs. By prioritizing these approaches, manufacturers can address common challenges in aluminum handle extrusions while maintaining a commitment to waste reduction.

The durability of aluminum handles is a critical factor in meeting consumer expectations and industry standards. Recent studies indicate that approximately 70% of consumers prioritize product longevity when selecting aluminum products for various applications, such as furniture and automotive components. This underscores the necessity for manufacturers to adopt innovative solutions that enhance the resilience of aluminum handle extrusions. Advanced anodization techniques and alloy modifications can significantly improve resistance to corrosion and wear, extending the life cycle of these products.

Furthermore, incorporating additives and protective coatings can play a pivotal role in enhancing the overall durability of aluminum handles. According to a report by the Aluminum Association, implementing these innovations can reduce maintenance costs by up to 30%, providing a substantial economic advantage for manufacturers. Additionally, not only do these solutions improve performance, but they also align with sustainability goals by reducing the frequency of replacements and waste. By embracing these technological advancements, manufacturers can create aluminum handles that meet stringent durability requirements while also enhancing customer satisfaction.