When embarking on a construction project, one of the critical decisions involves selecting the right materials, particularly when it comes to safety and efficiency. Aluminum scaffolding pipes are increasingly favored in the construction industry due to their lightweight nature and robust strength. According to industry expert Michael Johnson, "Choosing the right Aluminum Scaffolding Pipe can significantly impact both the safety and productivity of your project." His insight emphasizes the importance of making informed choices during the selection process.

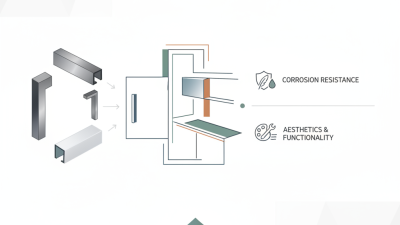

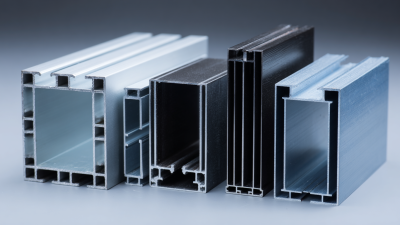

Aluminum scaffolding pipes serve as the backbone of many scaffolding systems, providing necessary support and stability. Understanding the qualities and specifications of these pipes—such as their load capacity, diameter, and finish—can help project managers tailor their choices to meet specific project demands. With various options available in the market, it is vital to consider factors like environmental conditions, the scale of the project, and compliance with safety standards.

Ultimately, selecting the best Aluminum Scaffolding Pipe is not just about meeting basic requirements; it's about enhancing the overall efficacy of a project while ensuring the safety of all personnel involved. As we explore the essential criteria for choosing the appropriate aluminum scaffolding pipe, it will become clear that the right choice can lead to greater efficiency and success in any construction endeavor.

When selecting aluminum scaffolding pipes for your project needs, several critical factors must be considered to ensure safety, durability, and efficiency. First, it's essential to look at the weight capacity of the scaffolding. According to industry standards, typical aluminum scaffolding can support weights ranging from 2,500 to 6,000 pounds per unit, depending on the configuration and material quality. This capacity is vital for ensuring the safety of workers and the equipment being used during construction or repair tasks.

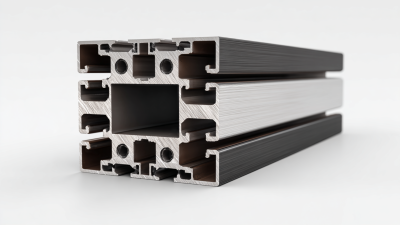

Another crucial aspect is the diameter and thickness of the aluminum pipes. Industry reports suggest that thicker pipes can provide greater stability and resistance to bending under load. Generally, scaffolding pipes with a diameter of 60-70 mm and a thickness of approximately 2.5 mm are recommended for standard construction projects. Additionally, consider the type of construction site and environmental conditions. For outdoor use, lightweight, corrosion-resistant aluminum pipes are preferable, as they can withstand various weather conditions while maintaining structural integrity.

Finally, verify compliance with established safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the American National Standards Institute (ANSI). Ensuring that the aluminum scaffolding pipes meet these guidelines not only protects workers but also enhances the overall efficiency of the project, minimizing the risk of accidents and delays.

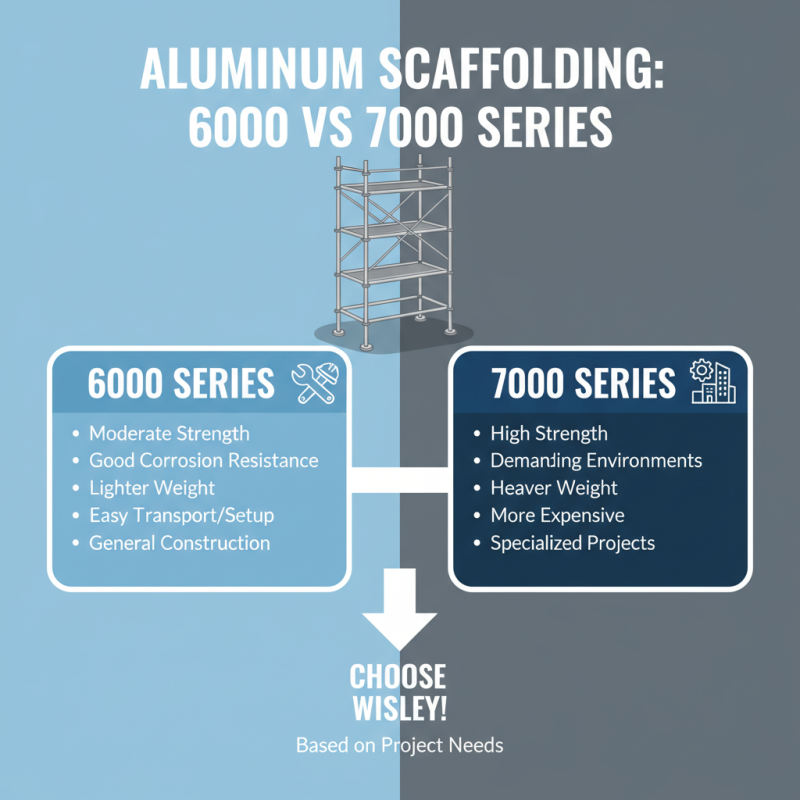

When selecting aluminum scaffolding for your project, it's crucial to understand the different types of aluminum scaffolding materials available. Aluminum scaffolding is favored for its lightweight nature, which allows for easy transportation and setup, but not all aluminum is created equal. There are primarily two types of aluminum used in scaffolding: 6000 series aluminum and 7000 series aluminum. The 6000 series offers good corrosion resistance and moderate strength, making it suitable for most construction tasks. In contrast, the 7000 series is known for its high strength and is often used in more demanding environments, though it may be heavier and more expensive.

**Tip:** Always consider the specific requirements of your project before making a choice. If your project involves lighter tasks, the 6000 series may suffice. However, for heavy-duty applications, investing in the 7000 series could enhance safety and efficiency.

Additionally, it’s essential to evaluate the structural design of the scaffolding. Some designs offer greater load capacities and stability, while others prioritize portability. When assessing different aluminum scaffolding, look for certification marks that indicate compliance with safety standards.

**Tip:** Look for features such as slip-resistant surfaces and locking mechanisms, which can significantly improve the safety of your scaffolding setup.

When selecting aluminum scaffolding pipes for your project, it's crucial to understand the safety standards and regulations that govern their use. Proper adherence to these standards not only ensures the safety of workers but also enhances the overall quality of the scaffolding structure.

Major safety guidelines, such as those from OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute), outline requirements for load capacity, stability, and proper assembly and disassembly of scaffolding systems. Compliance with these regulations is essential for any construction project that involves elevated work.

In addition to adhering to safety standards, it is important to conduct regular inspections and maintenance of the scaffolding equipment. This includes checking for any signs of wear or damage, ensuring that all components are securely fastened, and confirming that the scaffolding is erected on stable ground.

Training workers on the proper use and potential hazards associated with aluminum scaffolding is also necessary to prevent accidents and ensure a safe working environment. By prioritizing safety regulations and routine checks, project managers can create a secure and compliant workspace that minimizes risks for everyone involved.

When it comes to choosing the right aluminum scaffolding pipe for your project, understanding the load capacity requirements is essential. Load capacity refers to the maximum weight the scaffolding can safely support, which is influenced by the materials used, the design of the scaffold, and the assembly method. This information is critical not only for safety but also for ensuring that your project can be executed efficiently without interruptions due to structural failures.

To determine the load capacity, start by identifying the types of loads your scaffolding will bear, which can include workers, tools, and materials. Consider both static loads (the weight of items that are stationary) and dynamic loads (forces applied by people moving or working on the scaffold). Additionally, it's important to factor in potential environmental influences, such as wind or rain, which may affect stability.

Tips: Always consult with scaffolding professionals who can assist in calculating the required load capacity based on your specific needs. Ensure you leverage high-quality components and follow the manufacturer’s guidelines for assembly and use. Regular inspections and maintenance are vital to uphold safety standards over time, thus ensuring your scaffolding performs optimally throughout the project duration.

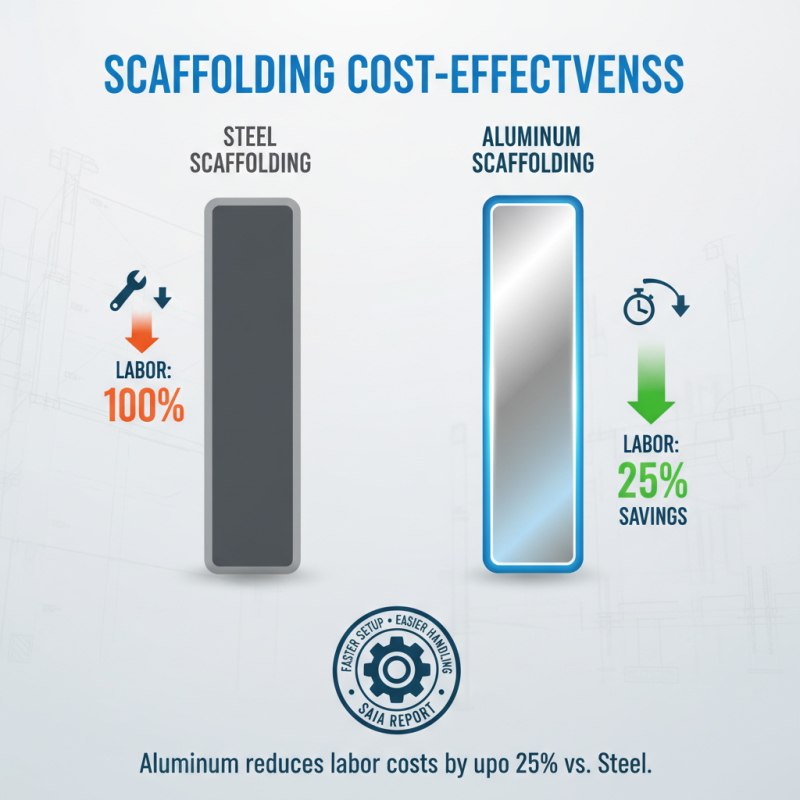

When considering scaffolding options, understanding the cost-effectiveness of aluminum compared to other materials is crucial. Aluminum scaffolding pipes are often favored for their lightweight and durable characteristics. According to a report by the Scaffold and Access Industry Association (SAIA), aluminum scaffolding can reduce labor costs by up to 25% due to easier handling and faster setup times compared to traditional steel scaffolding. This efficiency translates into substantial savings for construction projects where time is a critical factor.

In contrast, while steel scaffolding typically has a lower upfront cost, it can incur higher long-term expenses. A study from the Occupational Safety and Health Administration (OSHA) highlighted that the greater weight of steel can lead to increased transportation and labor costs. Furthermore, steel is prone to corrosion, necessitating regular maintenance and potential replacement. In terms of longevity and lifecycle cost, aluminum scaffolding typically outperforms steel, with an average lifespan exceeding 15 years with proper care, compared to a lifespan of around 10 years for steel scaffolding. This long-term durability enhances the overall value of aluminum, making it not just a lightweight alternative but also a more economically viable choice in the long run.