In the realm of contemporary architectural design, the selection of materials plays a pivotal role in achieving both aesthetic appeal and energy efficiency. Among these materials, Broken Bridge Aluminum Profiles have gained considerable traction due to their superior thermal insulation properties, which are critical for enhancing building performance. According to a recent report by the International Aluminum Association, buildings utilizing advanced aluminum profiles can reduce energy consumption by up to 30%, demonstrating a compelling return on investment for thoughtful design choices.

Industry expert Dr. Emily Turner, a leading voice in architectural materials science, emphasizes the importance of selecting the right profiles for specific applications. She states, "The use of Broken Bridge Aluminum Profiles not only contributes to the sustainability of a project but also elevates the overall design through versatility and strength." This insight reflects the growing recognition of aluminum profiles as essential components in reducing the carbon footprint of new constructions.

As architects and builders embark on their projects, understanding the nuances of Broken Bridge Aluminum Profiles becomes imperative. In this guide, we will explore key considerations and tips to help professionals make informed decisions, ensuring that their building projects are not only visually stunning but also strategically aligned with modern sustainability goals.

Broken bridge aluminum profiles have become a popular choice for modern building projects due to their excellent thermal insulation properties and durability. These profiles are designed with a polyamide strip that acts as a thermal break, significantly reducing heat transfer. According to a recent report by the Aluminum Extruders Council, this thermal efficiency can lead to energy savings of up to 30% in residential and commercial buildings, making them a favorable option for energy-conscious builders.

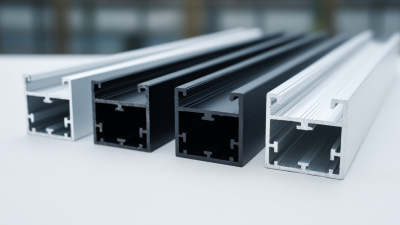

When selecting the best broken bridge aluminum profiles, it's essential to consider factors such as profile thickness and the types of finishes available. Profiles with a thickness of at least 1.4mm provide increased strength and better performance in adverse weather conditions. Additionally, various finishes can enhance aesthetic appeal while providing protection against corrosion.

**Tips:** Always check for certifications that indicate compliance with industry standards. Look for profiles that have been tested for thermal performance and structural integrity. Also, consider working with reputable suppliers who can provide detailed technical specifications to ensure optimal performance for your specific project needs.

When selecting broken bridge aluminum profiles for building projects, it's crucial to consider several key features that can significantly impact the overall performance and aesthetic appeal of your structure. One of the primary features to assess is thermal insulation. High-quality aluminum profiles should have effective thermal breaks to reduce energy consumption and enhance comfort within the building. This ensures that indoor temperatures remain stable, regardless of external weather conditions.

Another important aspect to evaluate is the durability of the profiles. Look for aluminum that is resistant to corrosion and weather-related wear. Choosing profiles with a high-quality finishing, such as powder coating, can enhance their longevity and reduce maintenance requirements. Always check the manufacturer’s specifications regarding the profiles’ performance under various environmental conditions.

**Tips:** When selecting aluminum profiles, consider asking for samples to assess their weight and feel. It’s also wise to consult with professionals about the best profiles suited to your specific project needs to avoid costly mistakes down the line. Additionally, ensure the supplier offers a warranty, which can provide peace of mind regarding your investment.

When selecting broken bridge aluminum profiles for your building projects, it is crucial to evaluate their thermal insulation properties, as these significantly impact energy efficiency and indoor comfort. Broken bridge aluminum profiles are designed with a thermal break—a non-conductive material that separates the internal and external aluminum sections. This design minimizes heat transfer through the profiles, thereby enhancing insulation. The effectiveness of these profiles will largely depend on the quality of the thermal break material and the design, which should be tailored to your local climate conditions.

In addition to the thermal break, the overall construction of the aluminum profiles plays a vital role in their insulation capabilities. Look for profiles that have been tested for thermal transmittance, indicated by a low U-value, which represents heat transfer. Choosing profiles with a design that incorporates multiple air chambers can further improve thermal performance. By prioritizing these factors, you can ensure that your building projects have enhanced energy efficiency, leading to lower heating and cooling costs and a more sustainable building solution.

When selecting broken bridge aluminum profiles for building projects, a significant factor to consider is their aesthetic and design flexibility. According to a report by the Aluminum Association, architectural aluminum has surged in popularity, accounting for over 70% of new residential constructions due to its lightweight and adaptable nature. The ability to customize profiles in terms of color, finish, and shape provides architects and designers with unparalleled freedom, allowing for innovative designs that can elevate a building's exterior.

Furthermore, studies indicate that the utilization of broken bridge aluminum profiles can enhance thermal efficiency without compromising aesthetic appeal. The National Institute of Standards and Technology highlights that utilizing these profiles can reduce thermal bridging by up to 40%, leading to improved energy performance. This dual advantage of sustainability and visual appeal makes broken bridge aluminum profiles an optimal choice for projects that require both functionality and style, providing an opportunity for builders to create modern and attractive facades while meeting energy efficiency standards.

When selecting broken bridge aluminum profiles for your building projects, cost-effectiveness plays a crucial role in making the right decision. Various profile brands can offer different pricing and quality levels, which directly impact your overall budget. A thorough comparison of costs, coupled with an evaluation of the product's lifespan and maintenance requirements, is essential. By considering these factors, you can mitigate future expenses and ensure a prudent investment.

**Tips:** Always request samples from multiple suppliers to assess durability and design before committing to a bulk order. Additionally, incorporate long-term performance metrics into your cost analysis—don't just focus on upfront costs. Analyzing the total cost of ownership over the lifespan of the aluminum profiles can provide clearer insight into their cost-effectiveness, ultimately guiding you toward the best option for your needs.

| Profile Type | Material Thickness (mm) | Thermal Insulation (W/m²K) | Cost per Meter ($) | Durability Rating (Years) |

|---|---|---|---|---|

| Standard Profile | 1.2 | 2.5 | 15 | 15 |

| Premium Profile | 1.5 | 1.9 | 22 | 20 |

| Economical Profile | 1.0 | 3.2 | 10 | 10 |

| High-Performance Profile | 1.8 | 1.2 | 30 | 25 |