Choosing the right Aluminium Extrusion Profile for your project can significantly influence not just the aesthetic appeal but also the overall performance and cost-effectiveness of the final product. With the global aluminium extrusion market expected to grow at a CAGR of 5.5% from 2021 to 2026, it’s crucial for designers and engineers to comprehend the variables that govern the selection process. According to a report by the Aluminium Association, proper selection can lead to a reduction in material waste and increased energy efficiency, highlighting the substantial impact of thoughtful decision-making in this domain.

Expert insights underscore the importance of understanding the properties and applications of different Aluminium Extrusion Profiles. As noted by Dr. Susan Blake, a leading authority in the field, “Selecting the most appropriate Aluminium Extrusion Profile is not merely a technical choice; it is an imperative component of sustainable design.” This perspective echoes the current industry trends focusing on sustainability and innovation, reinforcing the necessity to align profile selection with project goals and environmental considerations. By carefully evaluating the attributes of various profiles, project leaders can enhance functionality, achieve desired finishes, and ultimately contribute to the longevity and success of their projects.

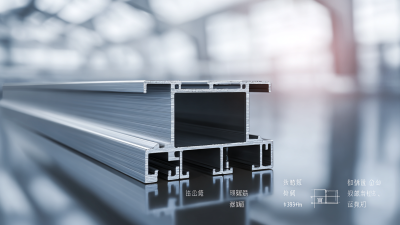

Aluminium extrusion profiles are versatile solutions used across various industries, providing a lightweight yet durable material that can be easily manipulated into different shapes. Understanding the different types of profiles is essential for selecting the right one for your project. Common profiles include square, rectangular, and custom shapes that can accommodate specific needs. For instance, a square profile can offer structural support, while a T-slot profile offers flexibility for assembly in modular design applications.

Applications of aluminium extrusion profiles are vast and varied. They are often employed in construction, automotive, and aerospace industries due to their strength-to-weight ratio and resistance to corrosion. In construction, aluminium profiles can be found in window frames, doors, and cladding systems, providing both aesthetic appeal and functionality. In the automotive sector, they are crucial for lightweight body components that enhance fuel efficiency, while in aerospace, bespoke extrusions are designed for intricate structural parts. Understanding these applications helps in making informed decisions about which profile best suits the requirements of your specific project.

When selecting the right aluminium extrusion profile for your project, several key factors should be carefully considered to ensure optimal functionality and efficiency. First, assess the specific requirements of your application, such as load-bearing capacity, environmental conditions, and aesthetic preferences. Understanding the mechanical properties needed—such as strength, weight, and corrosion resistance—will guide you toward the most suitable profile design.

Additionally, the dimensions and tolerances of the extrusion play a crucial role in achieving a perfect fit for your project. Consider the space constraints and how the aluminium profile will integrate with other components. This consideration ensures compatibility and minimizes the risk of performance issues down the line. Furthermore, the production method and the finishing options available should align with your timeline and budgetary constraints, thus allowing for a smooth project execution while meeting all necessary specifications.

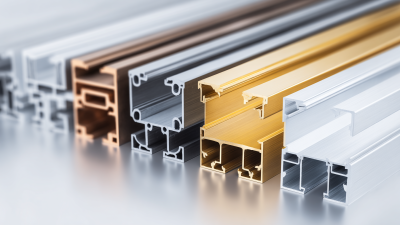

Aluminium extrusion profiles come in various shapes and sizes, each designed for specific applications. One of the most common types is the rectangular profile, which is widely used in construction and fabrication. This versatile shape provides a strong and stable base for structures, making it ideal for window frames, door frames, and other architectural elements. Additionally, rectangular profiles are favored in industrial applications for creating durable equipment and machine parts.

Another popular choice is the angle profile, which features a 90-degree angle. This profile is particularly useful for providing structural support in frameworks and supports in projects ranging from furniture to shelving systems. The angle profile is also beneficial in scenarios where space is limited, as it can be easily integrated into tight corners and areas. Similarly, T-slot profiles are designed with a groove that allows for easy assembly and adjustment, making them perfect for modular constructions, workstations, and robotics.

Finally, round and oval profiles are also utilized for their aesthetic appeal and functionality. These profiles are often found in furniture design, decorative applications, and railings, where a sleek and modern look is desired. Understanding the common types of aluminium extrusion profiles and their specific uses can significantly enhance project outcomes, enabling designers and engineers to choose the most appropriate options for their needs.

| Profile Type | Common Uses | Advantages |

|---|---|---|

| Square Extrusions | Frameworks, Structural Support | Strong, Versatile, Easy to Connect |

| Rectangular Extrusions | Casing, Housing, Racks | Efficient Use of Space, Sturdy |

| T-Slot Extrusions | Modular Enclosures, Workstations | Flexible Design, Easy to Reconfigure |

| Round Extrusions | Piping, Handles, Balustrades | Lightweight, Aesthetic Appeal |

| Z-Section Extrusions | Roof Frames, Wall Supports | High Load, Excellent Wind Resistance |

When selecting the right aluminium extrusion profile for your project, evaluating the strength and durability of the aluminium profiles is critical. Aluminium’s inherent properties, such as its lightweight nature and resistance to corrosion, make it a preferred material in various industries including construction, automotive, and aerospace. According to a report by the Aluminium Association, aluminium extrusions can achieve tensile strengths ranging from 200 to 700 MPa, depending on the alloy and temper. This broad range allows for tailored solutions that align with specific project requirements, ensuring optimal performance under various load conditions.

Durability is another pivotal aspect when considering aluminium profiles. The behaviour of aluminium under environmental stress, including temperature fluctuations and exposure to moisture, plays a significant role in its longevity. A study published in the Journal of Materials Science revealed that treated aluminium profiles can endure more than 10,000 hours of salt spray exposure without significant degradation, showcasing their robust nature in harsh environments. Moreover, advancements in anodizing and other protective coatings have further enhanced the durability of aluminium extrusions, making them better suited for applications where resilience is essential. By focusing on these key metrics, project managers can make informed decisions that balance performance and longevity in their aluminium extrusion selections.

This chart compares the tensile strength and yield strength of different aluminium alloy profiles commonly used in construction and manufacturing. The data reflects various grades of aluminium to help in choosing the right profile for your project based on strength and durability.

When embarking on a project that requires aluminium extrusion, sourcing the right supplier is a pivotal step in ensuring quality and cost-effectiveness. Start by outlining your budget, as this will guide your search toward suppliers who can meet your financial requirements. Consider obtaining quotes from multiple suppliers to gauge pricing while also paying attention to their minimum order quantities, which can affect your overall project costs. A clear understanding of your budget allows you to filter out options that may not align with your financial plan, leading to more efficient negotiations.

In addition to pricing, evaluate potential suppliers based on their reputation and production capabilities. Research their track record in delivering on time and maintaining quality standards. Request samples of their products to assess the finish and properties of the aluminium profiles that would suit your project's needs. Establishing open communication with suppliers can further aid in understanding their procurement processes and lead times. By combining a well-defined budget with thorough research into suppliers, you can select the right partner who will help bring your aluminium extrusion project to life while also adhering to your budget constraints.