Choosing the right aluminum handle extrusions is crucial for any project. According to industry reports, demand for aluminum extrusions is projected to grow by 5.5% annually. This growth reflects aluminum's versatility and strength. Using aluminum handle extrusions can enhance both functionality and aesthetics in design.

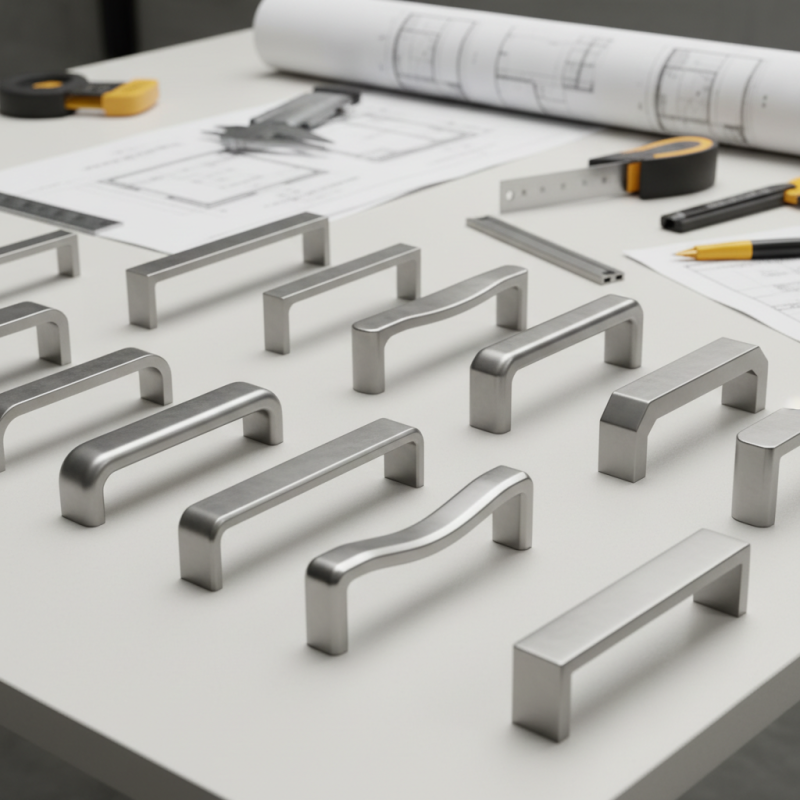

When selecting aluminum handle extrusions, consider the application’s specific requirements. For example, the extrusion shape plays a vital role in performance and ergonomics. A recent survey highlighted that 73% of designers cite usability as a top priority. Therefore, the right handle can significantly impact user experience.

However, it’s important to acknowledge potential challenges. Not every extruded aluminum handle may meet durability standards. A flawed choice might lead to project delays and increased costs. Reflecting on these factors ensures a well-informed decision. A deeper understanding of aluminum handle extrusions can lead to optimal results.

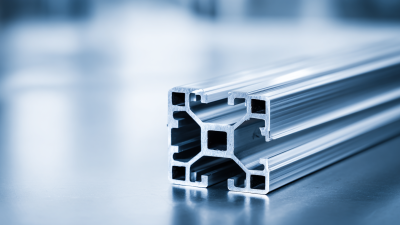

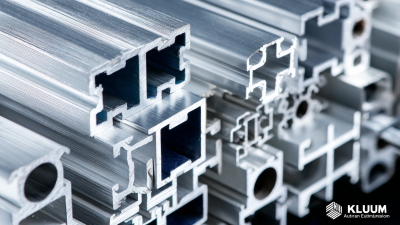

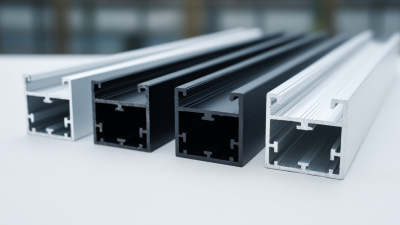

Aluminum handle extrusions are essential in various projects. These extrusions provide strength and versatility. Understanding their features can help you choose the right one. They vary in shape, size, and finish. You can find options with smooth or textured surfaces. The right choice depends on your project's purpose.

Tips for selecting aluminum handle extrusions: Consider the environment. Will the handles be exposed to harsh conditions? If so, choose a finish that can withstand corrosion. Think about the weight. Some projects need lighter materials for easy handling. Others require robust options for durability.

Also, analyze how the handle feels in your hand. A good grip is crucial. If unsure, test different styles to find the best fit. Pay attention to your design. Sometimes, style matters as much as function. Balancing both can be tricky but rewarding. Reflect on these aspects to improve your project outcomes.

When starting a project involving aluminum handle extrusions, it’s crucial to define your specific requirements. Consider factors like dimensions, weight capacity, and intended use. Think about where the handle will be applied. An outdoor project may require different specifications than an indoor one.

Tips: Make a list of essential features. Visualize the handle in action. This can help in determining the necessary strength and design.

Don’t overlook the importance of aesthetics. The finish and color can affect how the handle integrates into your design. A sleek, modern finish might not suit a vintage project. It’s all about harmony.

Tips: Gather samples for comparison. This will provide insight into how different finishes can affect the look. Reflect on your choices; ask if they truly meet your vision.

| Project Requirements | Specifications | Material Thickness | Finish Type | Weight Capacity |

|---|---|---|---|---|

| Residential Door Handles | Standard Ergonomic Design | 2 mm | Anodized Finish | 50 lbs |

| Industrial Equipment Handles | Heavy Duty Design | 3 mm | Powder Coated | 150 lbs |

| Furniture Handle Extrusions | Stylish and Functional | 1.5 mm | Brushed Aluminum | 30 lbs |

| Outdoor Equipment Handles | Corrosion Resistant | 2.5 mm | Baked Enamel Finish | 100 lbs |

When evaluating different types of aluminum handle extrusions, the focus should be on their functionality and application. Aluminum extrusions offer various profiles, including round, square, or custom shapes. Each type serves unique purposes in construction, machinery, or consumer products. According to the Aluminum Association, aluminum handles account for approximately 15% of total aluminum use in manufacturing. This statistic highlights their significant role across various sectors.

Durability is crucial when selecting aluminum handles. The extrusion manufacturing process allows for precise dimensions and increased strength. Reports indicate that extruded aluminum handles can withstand tensile loads up to 300 MPa. Such strength ensures reliability in high-demand environments, though it is essential to match the handle type with specific operational requirements. For instance, using a lightweight profile may seem efficient, but it could lead to higher failure rates in heavy-duty applications.

The finish of aluminum extrusions cannot be overlooked. Anodizing, powder coating, or brushing can enhance aesthetics and resilience. Yet, some finishes may be less durable under certain environmental conditions. It’s vital to test the handle in realistic scenarios. Despite numerous options available, the perfect handle for every project does not exist. Each has its advantages and drawbacks that require careful consideration.

When choosing aluminum handle extrusions, weight, strength, and durability are crucial. The specific application will dictate the requirements of these factors. For example, lighter extrusions are preferred in portable tools. In contrast, heavier options provide more strength for structural applications. Reports show that aluminum's strength-to-weight ratio is one of the highest among metals. This makes it ideal for various projects.

Durability is another key consideration. Aluminum is resistant to corrosion, which enhances its lifespan significantly. Studies indicate that anodized aluminum can increase the material's resistance, making it suitable for outdoor applications. However, it's essential to consider environmental conditions. For instance, extreme temperatures can affect performance.

Tips: Always assess the environmental factors your handles will face. Testing strength in real-world conditions can help you gauge durability. Remember that not all extrusions are created equal, so research materials and processes thoroughly. Ideally, select extrusions that fit both your project's needs and budget. Be wary of compromising weight for strength without understanding the trade-off.

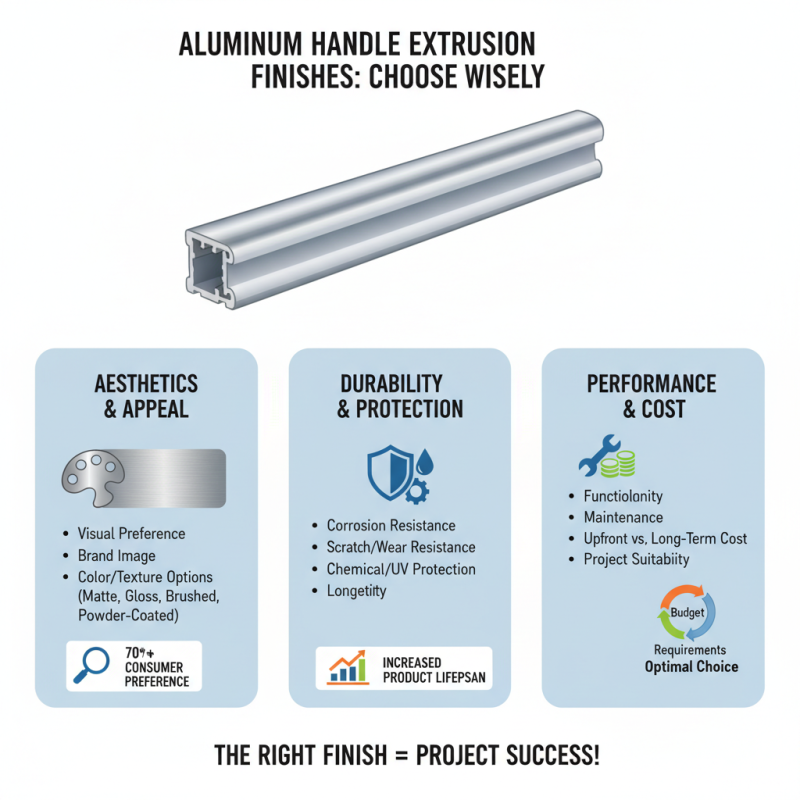

Choosing the right finish for aluminum handle extrusions significantly impacts your project’s success. Different finishes offer various benefits, from aesthetic appeal to durability. According to industry research, over 70% of consumers prefer products with an appealing finish. This preference often drives purchasing decisions, making the right selection crucial.

Surface treatments like anodizing or powder coating enhance both look and longevity. Anodizing increases corrosion resistance, which is vital for outdoor applications. Powder coating provides a vibrant color range, allowing for customization. In fact, studies show that a well-finished product can boost brand perception by up to 40%. However, not every finish suits every project. Ensure compatibility with each application to avoid costly mistakes.

Aesthetic choices often reflect the intended use. For example, a modern setting might require sleek, minimal designs. In contrast, rustic environments benefit from textured finishes. It's essential to balance style with function. Many designers overlook the subtle differences that a finish can make. Testing multiple options in real-world scenarios can help pinpoint the best match. Always consider the long-term implications of your finish selection.