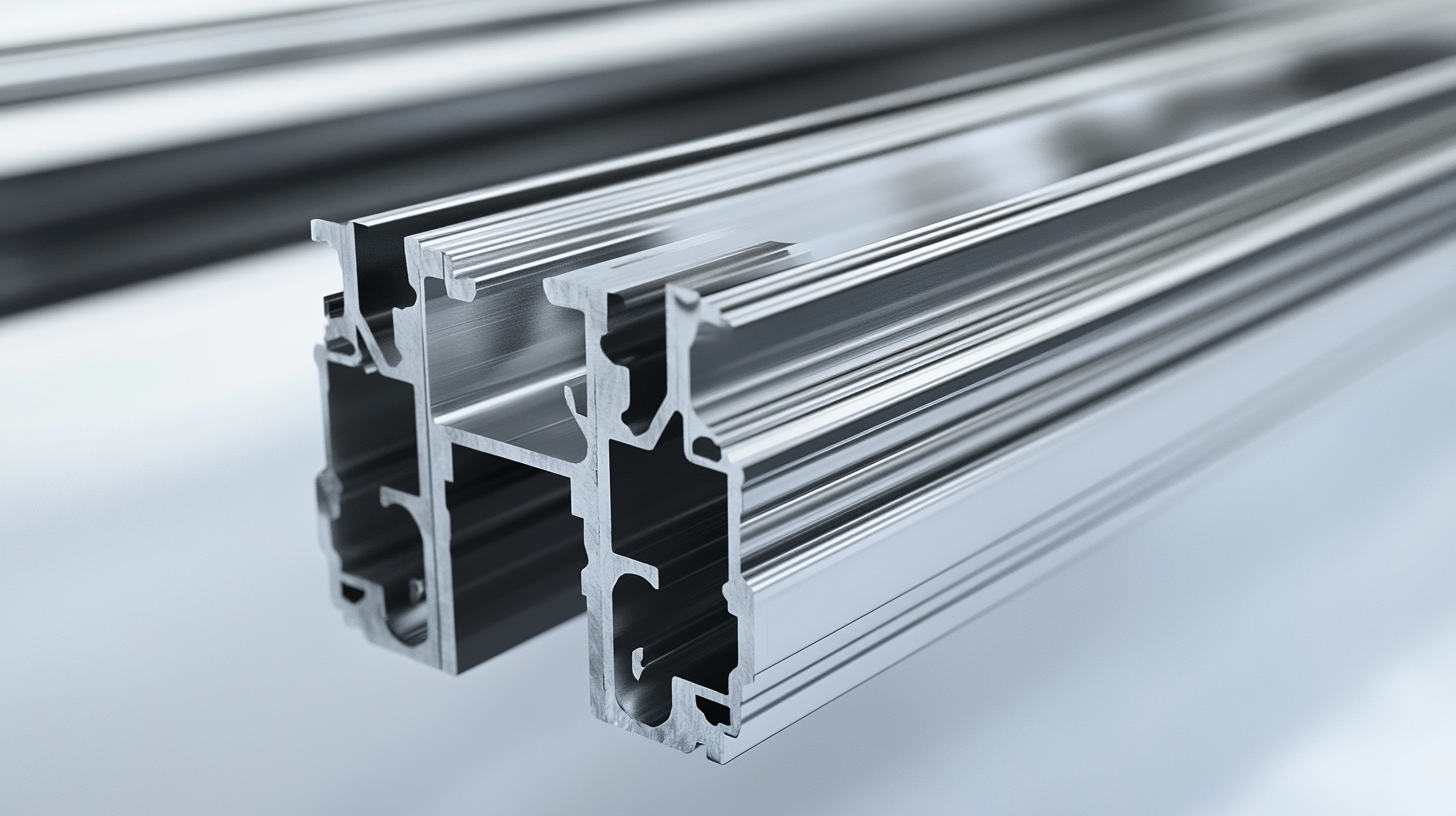

When embarking on a construction or design project, selecting the appropriate materials is crucial for ensuring durability, energy efficiency, and aesthetic appeal. Among the various options available, Thermal Break Aluminum Extrusion stands out as a top choice due to its superior insulating properties and structural integrity. According to a report by the Aluminum Association, approximately 70% of energy loss in buildings can be attributed to thermal bridging, highlighting the importance of incorporating effective thermal management solutions. Thermal Break Aluminum Extrusion not only mitigates this issue but also meets stringent building regulations and enhances the sustainability profile of a project. With a growing emphasis on energy efficiency, these extrusions are increasingly favored in modern architecture, promising both performance and design flexibility. Understanding the benefits of Thermal Break Aluminum Extrusion is essential for architects, builders, and designers aiming to achieve optimal results in their projects.

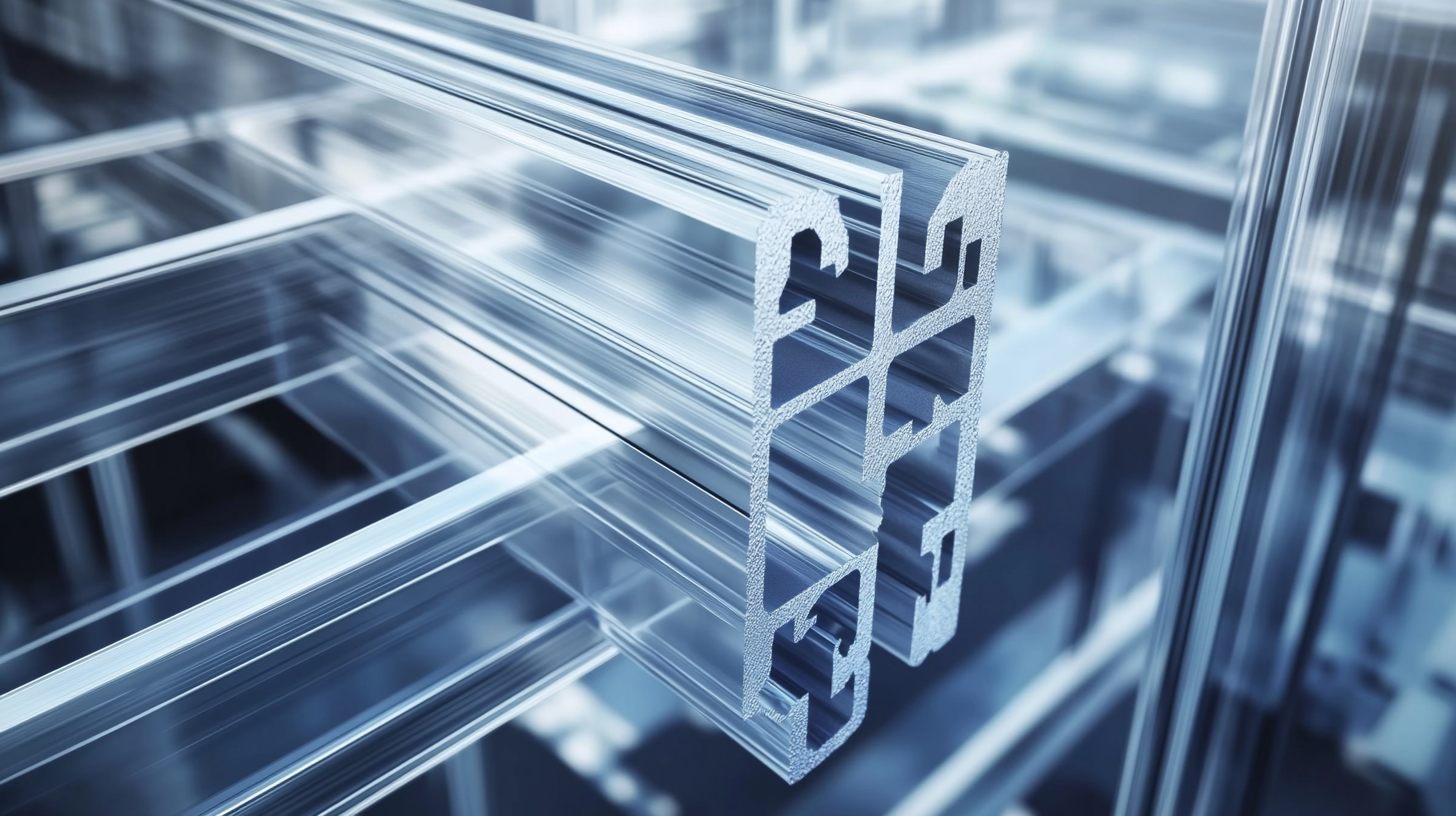

When embarking on a new project involving aluminum extrusions, understanding the significance of the thermal break is crucial. A thermal break in aluminum extrusions serves as an insulating barrier that reduces the transfer of heat or cold, effectively enhancing energy efficiency. This is particularly important in construction, where temperature control can significantly impact both comfort and energy costs. By incorporating thermal break technology, you can minimize condensation risks, prevent thermal bridging, and ensure a more sustainable building envelope.

Tip 1: When selecting thermal break aluminum extrusions, look for options with high-performance thermal insulation materials. The effectiveness of the thermal break can vary significantly based on its design and the materials used, so ensure that you evaluate the specifications carefully.

Tip 2: Consider the climate where the extrusions will be used. In hotter climates, a more robust thermal break can help maintain indoors at a comfortable temperature, while in colder locations, it can prevent heat loss. Tailoring your choice to your project’s geographic needs will enhance overall performance.

Tip 3: Don’t overlook aesthetic considerations. Many thermal break profiles can be designed to accommodate various architectural styles while providing the necessary insulation. Choose designs that harmonize with your project’s vision without compromising on functionality.

When selecting a manufacturer for thermal break aluminum extrusion solutions, several key factors should be taken into consideration to ensure that the choice aligns with project requirements. Firstly, quality control is paramount. A manufacturer must demonstrate rigorous quality assurance processes to maintain high standards through every stage of production. It's essential to inquire about their certifications, such as ISO, and any third-party testing that verifies the strength and durability of their thermal break products.

Secondly, assess the manufacturer’s experience and expertise in the thermal break solutions sector. A well-established manufacturer with a solid track record can offer invaluable insights into design optimization, material selection, and innovative engineering solutions. Their previous projects can serve as benchmarks for what to expect in terms of performance and reliability. Communication and support capabilities are also crucial; a responsive manufacturer who maintains open lines of communication will facilitate smoother project development and help navigate any challenges that arise.

| Key Factors | Description | Importance Level |

|---|---|---|

| Material Quality | Look for manufacturers that use high-grade aluminum and insulation materials. | High |

| Customization Options | Check if the manufacturer provides customization for specific project requirements. | Medium |

| Production Capacity | Assess if the manufacturer can meet your project's volume requirements. | High |

| Lead Time | Evaluate the turnaround time for orders to ensure timely project completion. | High |

| Cost Effectiveness | Compare pricing structures while ensuring quality is not compromised. | Medium |

| Technical Support | Ensure the manufacturer provides robust technical support during and after installation. | Medium |

| Sustainability Practices | Check if the manufacturer follows environmentally-friendly practices in their production. | Low |

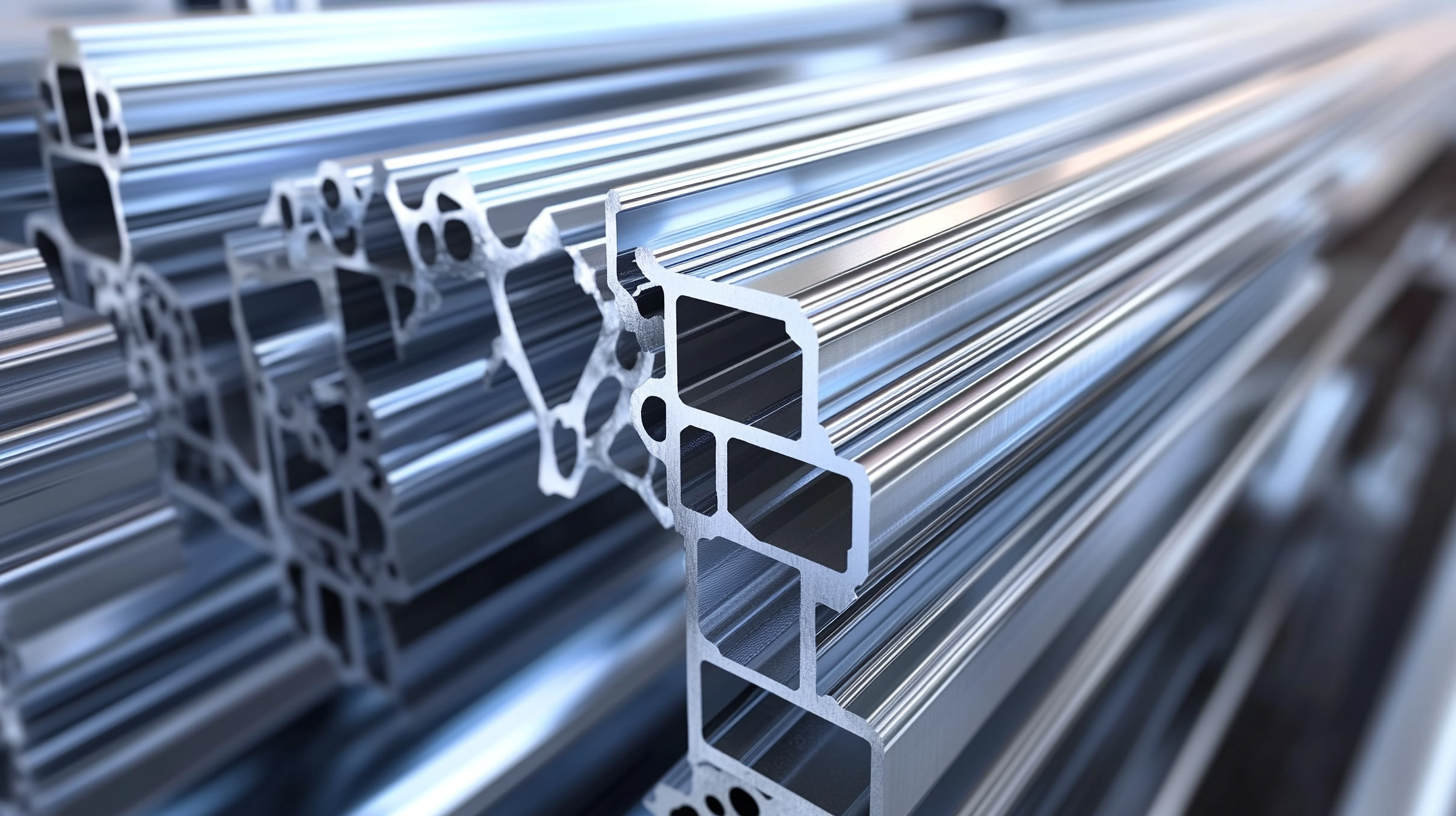

When selecting aluminum extrusions for your project, assessing material quality is paramount. Look for extrusions that conform to the industry standards set by organizations such as the Aluminum Association. Reports indicate that using high-quality aluminum alloys, like 6063 and 6061, can significantly enhance the durability and resistance to corrosion, ensuring that the final product meets both performance and aesthetic requirements.

**Tip:** Always check the material certification provided by the supplier to confirm that the aluminum meets the required specifications. This certification often includes details on mechanical properties, chemical composition, and compliance with industry standards.

In addition to certifications, consider the extrusion processes used. A well-controlled process can reduce defects and inconsistencies, which are critical for thermal break applications. Data from industry studies highlight that precision extrusions can improve thermal performance by up to 30%, making it essential to work with reputable manufacturers who utilize advanced technology and quality checks in their production.

**Tip:** Request samples before committing to a large order. Physical samples allow you to evaluate the finish, surface quality, and overall structural integrity of the aluminum extrusions, ensuring they are suitable for your project's demands.

When selecting a thermal break aluminum extrusion for your project, evaluating the manufacturer's experience and reputation is crucial. Research indicates that manufacturers with over a decade of experience are more likely to adhere to industry standards and deliver high-quality products. According to a report by the Aluminum Association, companies with established expertise not only understand the technical specifications but also the nuances of thermal performance, which can significantly impact the energy efficiency of your building.

**Tip:** Look for manufacturers with certifications from recognized industry organizations, as these can serve as a benchmark for quality and reliability.

Additionally, consider the manufacturer's track record in the market. A study published in the Journal of Architectural Developments highlights that 78% of successful projects were associated with reputable manufacturers known for their adherence to stringent quality controls. This suggests that partnering with a reputable supplier can lead to smoother project execution and better end results.

**Tip:** Seek testimonials or case studies from previous clients to gauge satisfaction levels and the performance of the thermal break extrusions in real-world applications.

When embarking on a project that involves thermal break aluminum extrusion, the delicate balance between cost and quality is paramount. Projects often operate under tight budgets, making it tempting to opt for the cheapest materials available. However, skimping on quality can lead to long-term issues such as reduced energy efficiency, higher maintenance costs, and premature failures. It is essential to conduct thorough research on various suppliers, evaluating their products based not only on price but also on the durability and performance of the materials offered.

Utilizing tools such as cost-volume-profit analysis can significantly aid in making informed decisions. By understanding the cost structure associated with different thermal break options, project managers can forecast profitability and make selections that will not only fit the budget but also meet the project’s quality standards. Furthermore, embracing data-driven decision-making can enhance the selection process. Analyzing data from past projects allows managers to assess the impact of previous choices on project outcomes, ultimately guiding them toward a more informed decision that balances upfront costs with long-term value.