When it comes to constructing safe and aesthetically pleasing environments, choosing the right Aluminium Handrail Extrusion is crucial. This guide aims to provide you with essential insights into selecting the perfect extrusion that meets both functional and design requirements for your projects. Aluminium handrail extrusions are not only vital for ensuring the safety of staircases, balconies, and walkways, but they also play a significant role in enhancing the overall visual appeal of your space. With various options available on the market, understanding the key factors—such as material quality, design versatility, and compliance with building regulations—can help you make an informed decision. By the end of this article, you will be equipped with the necessary knowledge to choose an Aluminium Handrail Extrusion that aligns with your construction needs, ensuring durability and style in your architectural endeavors.

When selecting the right aluminium handrail extrusion for your construction needs, it is crucial to identify your specific construction requirements. Begin by assessing the intended use of the handrail, whether it is for commercial spaces, residential properties, or outdoor structures. Each application may have different durability and aesthetic demands. For example, a handrail in a high-traffic commercial area may require more robust materials compared to one used in a residential setting. Additionally, consider the local building codes and regulations, which may dictate the height, spacing, and load requirements for handrails.

Next, take into account the environmental conditions the handrail will face. If the handrail will be exposed to harsh weather, selecting an extrusion with corrosion-resistant properties is essential. Anodized or powder-coated finishes can enhance the longevity of the handrail by providing an extra layer of protection against elements. Also, think about the design and style that will complement the overall architecture of the building. Whether you prefer a modern or traditional aesthetic, understanding your construction context will guide you in selecting an aluminium handrail extrusion that not only meets functional standards but also aligns with your design vision.

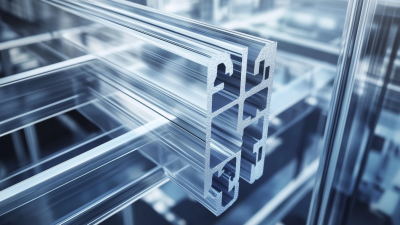

When selecting the right aluminium handrail extrusion for construction needs, understanding the different types of aluminium alloys is crucial. Aluminium alloy series such as 6061 and 6063 are commonly utilized in handrail applications. According to the Aluminum Association, 6061 is known for its excellent mechanical properties and corrosion resistance, making it suitable for structural components. Its tensile strength can reach up to 310 MPa, which is essential for ensuring safety in various environments.

On the other hand, 6063 is primarily favored for its aesthetic appeal and ease of fabrication. It is often used where complex shapes are needed, offering good extrudability and surface finish quality. Industry reports indicate that 6063 profiles typically show a yield strength of about 240 MPa, making them adequate for less demanding structural applications. When choosing between these alloys, the decision should be guided by the specific requirements of strength, aesthetics, and environmental conditions, ensuring that the selected extrusion not only meets legal safety standards but also enhances the overall design of the construction project.

When selecting the right aluminium handrail extrusion, it is essential to consider both aesthetic and functional design options to ensure that the final product meets your construction needs. Aluminium handrails offer a sleek, modern appearance that can enhance the overall look of a building. The variety of available finishes, such as anodized, powder-coated, or brushed, allows for customization that can complement any architectural style, from contemporary to traditional. Choosing a handrail style that aligns with your project's visual theme is vital, as the right design can significantly impact the perception of the space.

Functional design is equally important, as handrails must meet safety and accessibility standards while providing support to users. Consideration should be given to the diameter, height, and grip options of the handrails, ensuring they are comfortable and safe for users of all ages and abilities. Additionally, the installation method and durability of the materials used will affect the handrail's longevity and maintenance requirements. Balancing these aesthetic and functional aspects will help ensure that your choice of aluminium handrail extrusion contributes positively to both the visual appeal and the safety of the environment.

| Design Option | Aesthetic Appeal | Functional Benefits | Applications |

|---|---|---|---|

| Round Profile | Sleek and modern look | Good grip and comfort | Residential and commercial staircases |

| Square Profile | Contemporary and robust appearance | High strength and durability | Balconies and terraces |

| Flat Bar | Minimalist and industrial style | Ease of installation | Commercial buildings and public spaces |

| Custom Designs | Unique and personalized aesthetics | Tailored to specific safety requirements | Art installations and luxury properties |

When selecting aluminium handrails for construction projects, durability and maintenance are critical factors to consider. Aluminium’s resistance to corrosion and rust makes it an ideal material for outdoor environments, ensuring longevity even when exposed to harsh weather conditions. However, not all aluminium extrusions are created equal; the alloy composition can significantly influence durability. Higher-grade alloys provide enhanced strength and resistance to wear, making them more suitable for high-traffic areas or industrial applications.

Maintenance requirements can also vary depending on the finish applied to the aluminium extrusions. Powder-coated finishes, for example, not only enhance aesthetic appeal but also add a layer of protection against scratches and fading. Regular cleaning helps maintain the appearance and functionality of the handrails, but choosing a finish that can withstand environmental challenges will reduce the frequency of maintenance. Evaluating these factors during the selection process ensures that the aluminium handrail chosen will meet the specific needs of the construction project while minimizing long-term upkeep costs.

This chart illustrates the assessment of durability and maintenance factors in various types of aluminium handrail extrusions. Each type is evaluated on a scale of 1 to 10 based on its durability and maintenance requirements.

When selecting the right aluminium handrail extrusion for your construction project, understanding the cost variations and supplier options is crucial. Different suppliers may offer similar products at varying price points, influenced by factors such as material quality, manufacturing processes, and transportation expenses. It's essential to obtain quotes from multiple suppliers to get a comprehensive view of the market and determine where you might find the best value for your investment.

In addition to cost considerations, evaluating suppliers based on their reputation, customer service, and delivery timelines is vital. A supplier that provides excellent after-sales support and timely delivery can significantly impact the efficiency of your construction timeline. Prioritizing vendors who offer a balance between competitive pricing and quality assurance will help ensure the longevity and safety of the aluminium handrails you choose, ultimately leading to a successful outcome for your project.