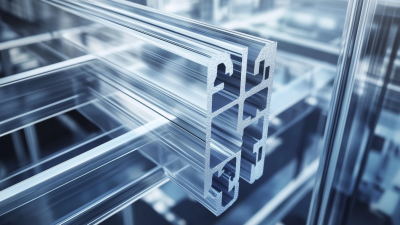

When embarking on a construction or renovation project, selecting the right materials is crucial for ensuring both performance and sustainability. Among the various options available, the Thermal Break Aluminum Profile stands out as an excellent choice, particularly for projects that demand energy efficiency and durability. These profiles are designed to minimize thermal transfer, making them ideal for windows, doors, and facades that face different environmental conditions.

Understanding the essential features and benefits of Thermal Break Aluminum Profiles can significantly impact the longevity and energy efficiency of your building. Factors such as thermal insulation properties, structural strength, and aesthetic flexibility are paramount in making an informed decision. Moreover, the right thermal break profile can also contribute to compliance with building regulations and energy standards, which are becoming increasingly stringent worldwide.

In this guide, we will explore the key considerations to keep in mind when choosing a Thermal Break Aluminum Profile for your project. By evaluating the various aspects such as design, performance specifications, and application suitability, you will be well-equipped to select a profile that meets your specific project needs, ensuring both functionality and visual appeal in your construction endeavor.

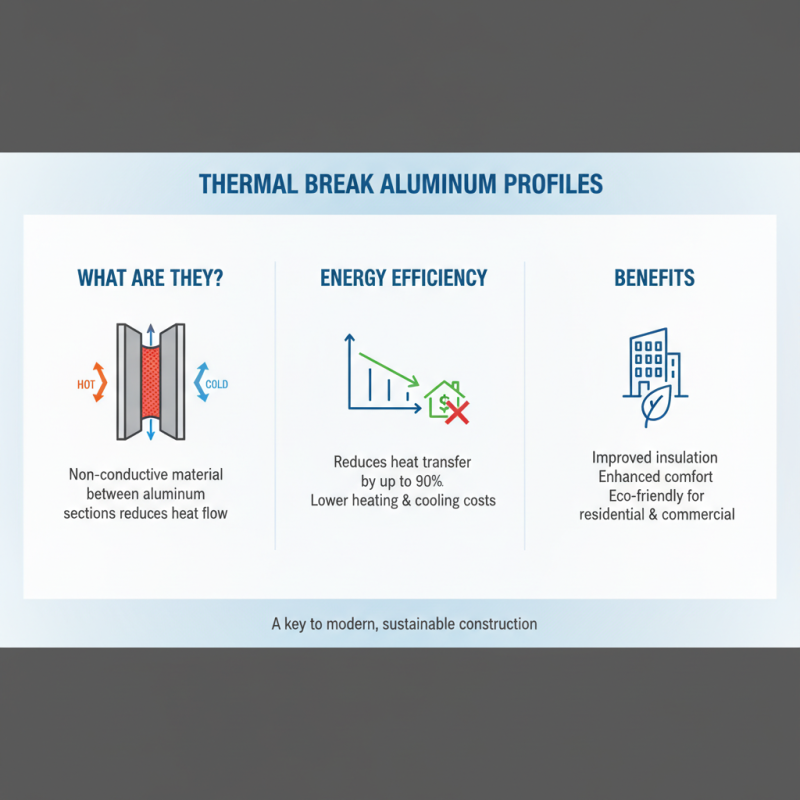

Thermal break aluminum profiles are integral to modern construction, playing a critical role in enhancing energy efficiency and structural performance. These profiles incorporate a non-conductive material between two aluminum sections, significantly reducing heat transfer. According to a study by the Department of Energy, buildings equipped with thermal break aluminum facades can reduce thermal bridging by up to 90%, leading to improved insulation and lower energy costs over time. This makes them a valuable asset in both residential and commercial projects.

When selecting thermal break aluminum profiles, it's vital to understand the key benefits they offer. They contribute to better thermal performance, which can lower heating and cooling expenses. Additionally, they minimize condensation risks, thereby preserving the integrity of the building materials. The choice of profile design and the quality of the thermal break material directly impact these performance qualities.

Tips: When evaluating thermal break options, consider profiles with higher insulation values (often labeled as U-values) for increased efficiency. Consulting with professionals to determine the appropriate specifications based on your project location and climate can lead to better long-term savings. Always check compliance with local building codes to ensure that your selections meet necessary standards.

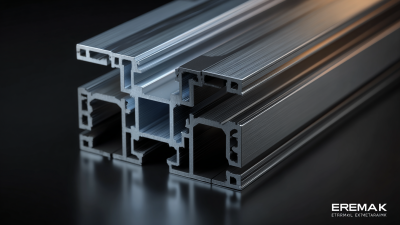

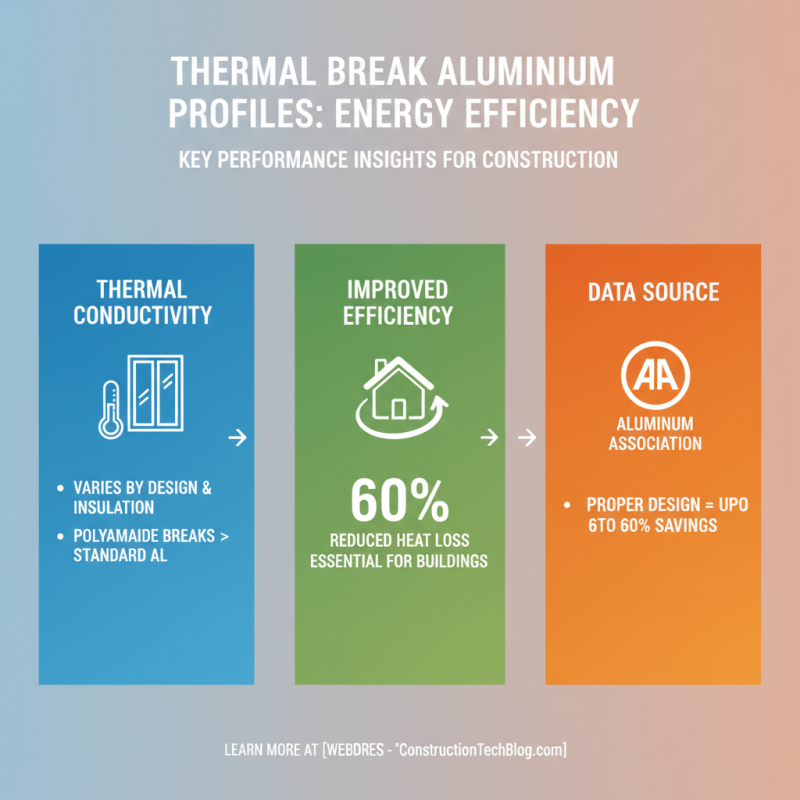

When selecting thermal break aluminum profiles for architectural and construction projects, several key factors must be analyzed to ensure both performance and efficiency. First and foremost, the thermal conductivity of the profile is crucial. According to the Aluminum Association, profiles with lower thermal conductivity significantly enhance energy efficiency by reducing heat transfer between indoor and outdoor environments. For instance, profiles with a thermal break of 0.2 W/m·K or lower can lead to energy savings of up to 30%, which is critical for meeting today's building energy codes.

Another key factor is the profile's structural integrity. The American Architectural Manufacturers Association (AAMA) emphasizes the importance of ensuring that the chosen profile meets local building codes and standards for strength and durability. Profiles should be tested for structural performance under various load conditions. Additionally, consider the profile's finish and resistance to environmental elements, which can affect long-term performance and maintenance. A study by the National Fenestration Rating Council (NFRC) highlights that profiles with protective coatings can prevent corrosion and degradation, thus extending the lifespan of the installation and enhancing its overall aesthetic appeal.

Lastly, assessing the environmental impact of the materials used in thermal break aluminum profiles is increasingly significant. Research indicates that aluminum is one of the most recycled materials globally, with a recycling rate exceeding 90%. Choosing profiles that support sustainability not only meets regulatory requirements but also appeals to eco-conscious consumers, providing a competitive edge in the marketplace. Evaluating these factors comprehensively ensures that the selected thermal break aluminum profile aligns with both performance expectations and environmental standards.

| Dimension | Material Type | Thermal Break Method | Application | Cost per Unit |

|---|---|---|---|---|

| 200mm x 100mm | Aluminum Alloy 6063 | Polyamide Strip | Windows and Doors | $15.50 |

| 200mm x 150mm | Aluminum Alloy 6061 | Thermal Epoxy | Curtain Wall Systems | $18.75 |

| 250mm x 100mm | Aluminum Alloy 7005 | Polyurethane | Structural Applications | $22.00 |

| 300mm x 150mm | Aluminum Alloy 6063 | Polyamide Strip | Skylights | $20.00 |

| 150mm x 100mm | Aluminum Alloy 6082 | Thermal Break Strips | Balconies | $12.00 |

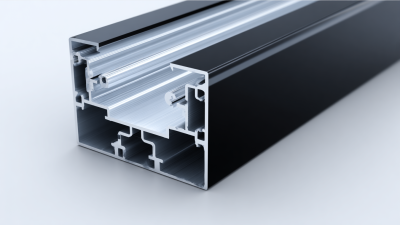

When selecting thermal break aluminum profiles for your project, understanding industry standards and certifications is crucial. These profiles are subject to various regulations that ensure their energy efficiency and structural integrity. For instance, the North American Fenestration and Insulation Manufacturers Association (NAFM) sets forth rigorous standards that aluminum profiles must meet, including thermal performance metrics. Reports indicate that compliant profiles can achieve a Thermal Transmittance (U-value) as low as 0.15 W/m²K, significantly contributing to energy savings in buildings.

In Europe, the European Standard EN 14024 outlines the requirements for aluminum profiles, emphasizing their resistance to environmental factors and energy efficiency. Additionally, profiles bearing the CE mark are tested for compliance with these standards, providing assurance that they meet strict performance criteria. Recent studies show that utilizing certified thermal break aluminum profiles can result in a reduction of heat loss by up to 60%, thus enhancing the energy performance of residential and commercial structures. Adopting these industry guidelines not only complies with construction regulations but also promotes sustainable building practices.

When selecting thermal break aluminum profiles for construction projects, understanding their thermal performance is crucial. Various studies indicate that the thermal conductivity of aluminum profiles can vary significantly based on their design and insulation methods. For example, profiles with polyamide thermal breaks exhibit lower thermal transmittance compared to standard aluminum, improving overall energy efficiency. Data from the Aluminum Association reveals that a properly designed thermal break can reduce heat loss by up to 60%, making it an essential feature in building applications.

In comparative analysis of different aluminum profiles, the effectiveness of thermal breaks can be assessed using parameters such as U-values and thermal transmittance ratings. A recent report from the Institute of Thermal Performance in Buildings highlighted that profiles with multi-chamber designs tend to offer superior performance by minimizing thermal bridging. The study found that enhancing the profile's design further can lead to a reduction in energy consumption by 15-20% in commercial buildings, supporting the case for investing in higher-quality thermal break profiles. Such data underscores the importance of choosing the right profile for optimal thermal performance, ultimately enhancing the building's sustainability and reducing operational costs.

When considering thermal break aluminum profiles for construction projects, a cost-benefit analysis is essential for making an informed investment. High-quality thermal break solutions often come with a higher upfront cost, but the long-term savings in energy efficiency can offset this initial expense. By reducing thermal bridges, these materials minimize heat loss during winter and heat gain in summer, leading to lower heating and cooling costs. Homeowners and businesses can achieve significant reductions in energy bills, which, over time, can result in substantial savings that outweigh the initial investment.

Furthermore, investing in high-quality materials enhances durability and lowers maintenance costs. Inferior thermal break profiles may lead to issues such as water infiltration, condensation, and thermal inefficiencies, resulting in costly repairs and replacements. In contrast, high-quality profiles provide better performance and longevity, ensuring that the initial investment pays off through reduced operational costs and fewer repairs. Consequently, the decision to invest in premium thermal break aluminum profiles is not just about the upfront price; it's about understanding the long-term value and returns that can arise from enhanced energy efficiency, lower utility expenses, and greater structural integrity.