When embarking on a construction or renovation project, selecting the right materials is crucial for ensuring durability, energy efficiency, and aesthetic appeal. Among the myriad options available, Broken Bridge Aluminum Profiles stand out as an exceptional choice for modern architecture. These profiles offer superior thermal insulation properties, making them an ideal solution for energy-efficient designs. In this ultimate guide, we will explore the various types of Broken Bridge Aluminum Profiles on the market, highlighting their unique features, benefits, and applications. By understanding the nuances of each profile, you can make informed decisions that enhance both the functionality and style of your projects. Whether you're an architect, contractor, or DIY enthusiast, this guide will equip you with the knowledge needed to choose the best Broken Bridge Aluminum Profiles tailored to your specific needs.

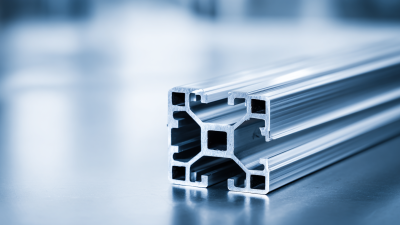

When it comes to selecting materials for construction and design projects, understanding the basics of broken bridge aluminum profiles is essential. These profiles are specially designed to improve thermal insulation and energy efficiency, making them a popular choice in modern architecture. Unlike traditional aluminum profiles, broken bridge variants incorporate thermal breaks that prevent the transfer of heat, thus minimizing energy loss and enhancing comfort within a building.

When it comes to selecting materials for construction and design projects, understanding the basics of broken bridge aluminum profiles is essential. These profiles are specially designed to improve thermal insulation and energy efficiency, making them a popular choice in modern architecture. Unlike traditional aluminum profiles, broken bridge variants incorporate thermal breaks that prevent the transfer of heat, thus minimizing energy loss and enhancing comfort within a building.

Choosing the right broken bridge aluminum profile involves considering various factors, such as wall thickness, design aesthetics, and the specific needs of your project. The profiles come in different shapes and sizes, allowing for versatility in applications ranging from windows to curtain walls. Additionally, the quality of the alloy used can significantly impact performance. By familiarizing yourself with these fundamental aspects, you ensure that your selection not only meets structural requirements but also aligns with the energy efficiency goals of your project.

When selecting broken bridge aluminum profiles for your projects, it is crucial to consider several key features that can significantly impact performance and durability. One of the most important factors is thermal insulation. According to a report by the Aluminum Association, broken bridge aluminum profiles can reduce thermal transmittance by up to 65% compared to traditional aluminum systems, making them an ideal choice for energy-efficient building designs.

Another critical feature to consider is structural integrity. High-quality aluminum profiles should comply with international standards, such as ISO 9001, to ensure they can withstand environmental stressors. A comprehensive report by the Architectural Aluminum Manufacturers Association cites that properly designed aluminum profiles can last over 50 years with minimal maintenance, thereby providing long-term value for your investment.

Tips: Always verify that the profiles you choose come with a reliable warranty, indicating the manufacturer's confidence in their product. Additionally, conduct a cost-benefit analysis to weigh the initial investment against long-term savings on energy and maintenance. Lastly, consider the aesthetic options available, as these profiles can be customized in various finishes to match your project's design needs.

When it comes to selecting broken bridge aluminum profiles for various projects, understanding the different types available is crucial. Broken bridge aluminum profiles are characterized by their thermal insulation properties, which are particularly beneficial in construction where energy efficiency is a priority. There are generally three main types of broken bridge aluminum profiles: thermal break profiles, conventional square corner profiles, and round corner profiles. Each type has its own set of advantages tailored for specific applications, from residential buildings to commercial structures.

Thermal break profiles are designed with an insulation layer that minimizes thermal conductivity, making them ideal for energy-efficient windows and doors. They help in maintaining consistent indoor temperatures, thereby reducing heating and cooling costs. On the other hand, conventional square corner profiles offer a clean, modern aesthetic and are widely used in mid-range residential projects. Finally, round corner profiles provide a softer aesthetic appeal, often preferred for high-end architectural designs where elegance and style are paramount.

Selecting the right profile type depends not only on aesthetic preferences but also on specific project requirements and performance criteria, making it essential for architects and builders to understand these distinctions thoroughly.

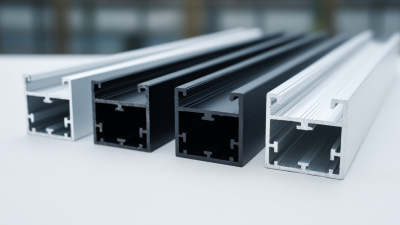

When selecting aluminum profiles for your projects, the choice between extruded and roll-formed profiles can significantly affect both the design and functionality of your final product. Extruded aluminum profiles are created by pushing aluminum through a die, allowing for complex shapes with high precision, which is particularly useful for architectural and structural applications. In contrast, roll-formed aluminum profiles are shaped by passing the material through a series of rollers, which can be more efficient for producing longer lengths with uniform cross-sections.

Recent innovations in manufacturing are enhancing the roll-forming process, particularly with the introduction of high precision four roll CNC bending machines that utilize servo electric cylinders. This development not only improves accuracy in profile bending but also facilitates the creation of sophisticated structures, such as microchannel profiles. Furthermore, a novel multi-container extrusion method has emerged, enabling the production of wide aluminum profiles with lower force requirements, thereby refining the extrusion process while maintaining material integrity. These advancements emphasize the importance of considering the manufacturing techniques of aluminum profiles in your project decisions.

When it comes to choosing broken bridge aluminum profiles for your projects, prioritizing quality and durability is essential. These profiles are known for their excellent insulation properties and resistance to wear and tear, making them suitable for a variety of applications. However, not all profiles are created equal. It’s crucial to select a reputable manufacturer and verify product specifications, as this will influence the longevity and performance of your final output.

One key tip for ensuring quality is to check the material's thickness and the quality of the aluminum used. Thicker profiles generally offer better strength and insulation. Additionally, consider the surface finish; a good quality finish not only enhances aesthetics but also provides added protection against environmental factors.

Another important aspect is to gather feedback from previous buyers. Customer reviews often highlight long-term performance and potential issues, offering insights that can guide you in making an informed choice. Lastly, looking into certifications can further assure you of the product's durability, as well-regarded standards reflect a manufacturer’s commitment to quality. By following these tips, you can ensure that your projects utilizing broken bridge aluminum profiles meet your expectations for durability and performance.

| Profile Type | Thermal Insulation Value (W/m²K) | Weight (kg/m) | Typical Applications | Durability Rating (Years) |

|---|---|---|---|---|

| Standard Broken Bridge | 2.0 | 3.5 | Residential Windows | 20 |

| High-Performance Insulated | 1.5 | 4.0 | Commercial Buildings | 30 |

| Architectural Series | 1.8 | 2.8 | Commercial Windows & Doors | 25 |

| Heavy-Duty Profiles | 2.2 | 5.0 | Industrial Applications | 35 |

| Minimalist Design | 1.9 | 2.5 | Residential and Commercial | 20 |