In the evolving landscape of construction and architectural design, the choice of materials plays a critical role in enhancing energy efficiency and aesthetics. Among the various options available, Insulated Aluminum Frame Profiles have garnered significant attention due to their superior thermal performance and durability. According to a recent report by the Global Building Materials Association, the market for insulated frame profiles is projected to grow by over 15% annually through 2025, highlighting the increasing demand for energy-efficient building solutions.

Industry expert Dr. Emily Sanders, a renowned architect and advocate for sustainable building practices, emphasizes the importance of selecting the right profile for both performance and design. She notes, "The effectiveness of Insulated Aluminum Frame Profiles lies not just in their insulation capabilities but also in their ability to seamlessly integrate with modern architectural styles." This sentiment echoes the growing trend among architects and builders to prioritize sustainability without compromising on aesthetics.

As we look toward 2025, understanding the key factors in choosing Insulated Aluminum Frame Profiles—such as thermal resistance, structural integrity, and design versatility—will be essential. This comprehensive approach will not only enhance the longevity of structures but will also contribute to a more sustainable future in construction.

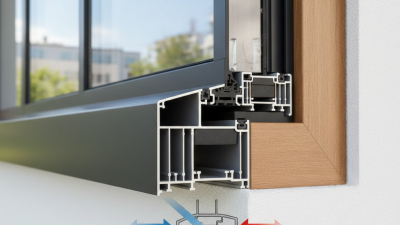

Insulated aluminum frame profiles play a crucial role in modern architectural projects, offering a unique combination of durability and energy efficiency. These profiles, designed with thermal breaks, effectively reduce heat transfer, making them ideal for climates with extreme temperatures. By preventing condensation and improving the overall thermal performance of a building, insulated frames help maintain a comfortable indoor environment while also minimizing energy costs. This not only contributes to sustainability efforts but also enhances the lifespan of the building materials.

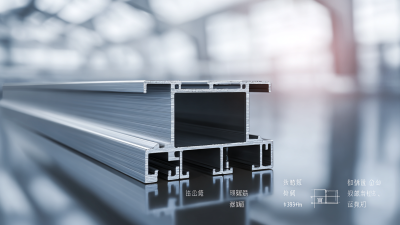

Moreover, insulated aluminum frame profiles are not only functional but also aesthetically versatile. They can be customized to fit various design requirements, offering architects a range of finishes and colors that complement any project. The lightweight nature of aluminum makes these profiles easier to handle and install, reducing labor costs and project timelines. By choosing insulated aluminum frames, project managers can achieve a balance between performance and style, resulting in a high-quality construction that meets contemporary standards for energy efficiency and design innovation.

When selecting insulated aluminum frame profiles for your next project, several key factors must be considered to ensure both functionality and aesthetics. First and foremost, evaluate the thermal performance of the profiles. Insulated frames are designed to minimize heat transfer, which is critical for energy efficiency. Consider the type and thickness of the insulation used, as well as the overall construction of the frame. Higher insulation values typically lead to better energy savings, making this an essential aspect for both residential and commercial applications.

Another critical factor is the profile's durability and maintenance requirements. Aluminum frames are known for their strength and resistance to weathering, but the finish and coatings can significantly impact longevity and appearance. Look for low-maintenance options that resist fading and corrosion to prolong the life of the materials. Additionally, assess the design flexibility; a versatile profile can accommodate various project requirements while remaining visually appealing. By prioritizing these elements, you'll ensure that your frame choice effectively meets the demands of the environment and enhances the overall design of your project.

| Factor | Description | Importance Level | Typical Applications |

|---|---|---|---|

| Thermal Insulation | The ability to reduce heat transfer, enhancing energy efficiency. | High | Commercial Buildings, Residential Projects |

| Structural Strength | Resistance to wind, snow loads, and other mechanical stresses. | High | High-Rise Buildings, Industrial Facilities |

| Aesthetic Appeal | Visual factors, including color, finish, and design versatility. | Medium | Residential Homes, Retail Spaces |

| Cost Efficiency | Overall cost considerations of materials and installation. | High | All Types of Construction Projects |

| Environmental Impact | Sustainability and recyclability of materials used. | Medium | Eco-Friendly Buildings, LEED Certified Projects |

| Ease of Maintenance | Long-term upkeep and maintenance requirements of the frames. | Medium | Commercial and Residential Projects with High Foot Traffic |

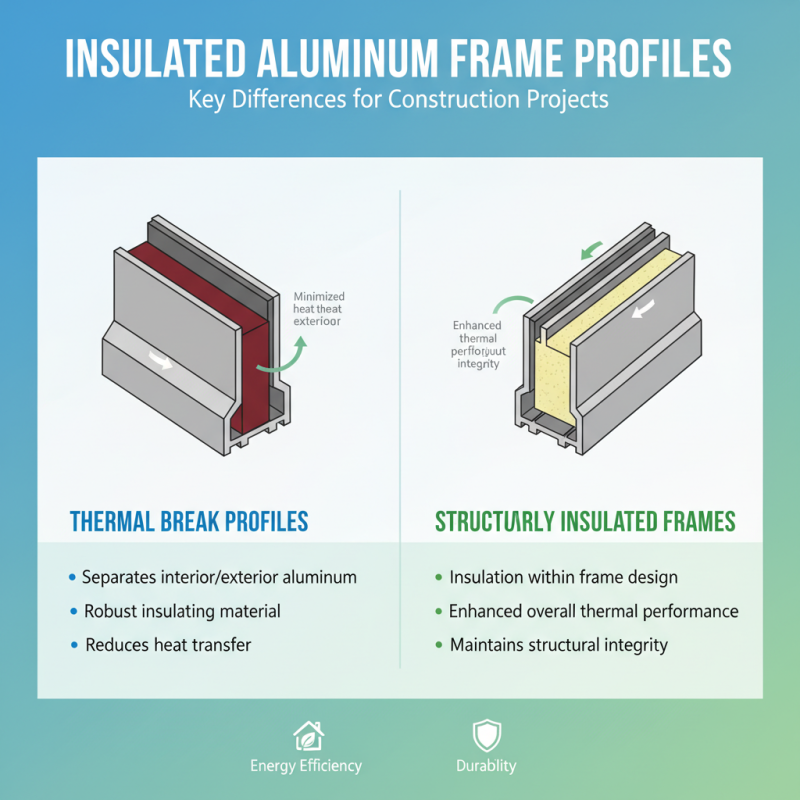

When selecting insulated aluminum frame profiles for your next construction project, understanding the key differences among the options available in the market is crucial. Insulated aluminum frames are known for their durability, energy efficiency, and aesthetic appeal, but not all profiles are created equal. The two primary types include thermal break profiles and structurally insulated frames. Thermal break profiles feature a robust insulating material that separates the interior and exterior aluminum, minimizing heat transfer and improving energy efficiency. On the other hand, structurally insulated frames incorporate insulation directly within the frame design to enhance the overall thermal performance without compromising structural integrity.

Beyond the basic types, it’s important to consider various factors such as thermal conductivity, strength, and design flexibility. The thermal conductivity rating of a profile determines how well it minimizes heat loss or gain, impacting the overall energy efficiency of your project. Strength ratings are equally important—profiles should withstand environmental stressors like wind and moisture while maintaining their appearance over time. Additionally, look for designs that offer flexibility in terms of customization, allowing you to match architectural elements seamlessly while adhering to any performance requirements. By assessing these elements critically, you can choose the right insulated aluminum frame profile that not only aligns with your project's needs but also enhances its overall functionality and aesthetic.

When it comes to installing insulated aluminum frame profiles, precision and attention to detail are paramount. The right installation techniques not only ensure the longevity of the profiles but also optimize their thermal performance. Begin by preparing the installation site, ensuring that all surfaces are clean and free of debris. It’s essential to use a level to check all areas where the profiles will be mounted to avoid future misalignments.

Tips: Utilize high-quality sealant to fill any gaps during the installation process. This will enhance insulation and prevent moisture ingress, protecting the integrity of the frames.

Next, pay close attention to the joining methods. Properly aligning and securing the profiles is crucial. You may need to use brackets or connectors specifically designed for insulated aluminum frames. Ensure that screws and fasteners are corrosion-resistant to maintain the durability of the installation over time.

Tips: Always pre-drill holes to avoid splitting the material. This technique can save you time and help maintain the structural integrity of the profiles during installation.

Finishing with trim or additional weatherproofing will provide extra protection against the elements. This is essential for maximizing energy efficiency and maintaining the aesthetic appeal of your project. With the right techniques and attention to detail, your insulated aluminum frame profiles will be a reliable feature for years to come.

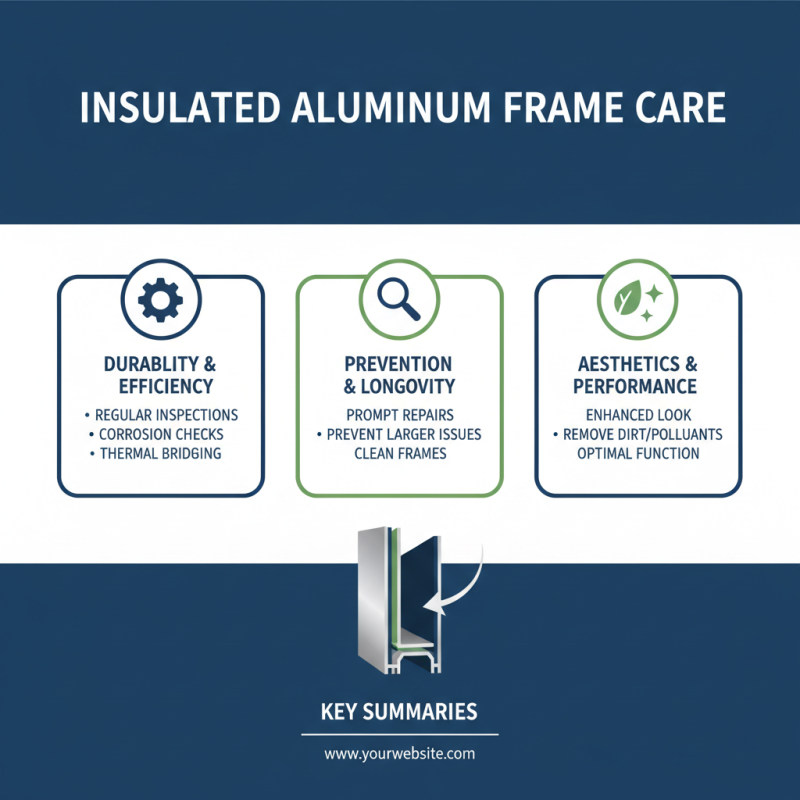

When it comes to maintaining and upgrading insulated aluminum frame structures, the focus should be on ensuring durability and efficiency while enhancing aesthetics. Regular inspections are crucial to identify potential weaknesses in the frame, such as corrosion or thermal bridging. By addressing these issues promptly, one can prevent larger problems down the line. It's essential to clean the frames periodically to remove dirt and pollutants that can compromise their longevity and performance.

Upgrading insulated aluminum frames can significantly improve energy efficiency and overall structural performance. Incorporating new insulation materials or enhancing existing ones can lead to better thermal performance, reducing energy costs and improving comfort levels within the space. Furthermore, adding advanced glazing options can enhance natural light intake while improving thermal regulation. Aesthetic upgrades, such as modern finishes and designs, not only boost the visual appeal but also increase the building's market value, making these upgrades a wise investment for any project.