In today's industrial landscape, the choice of the right Aluminium Extrusion Profile has become increasingly critical for the success of various projects, ranging from construction to automotive applications. According to a report by MarketsandMarkets, the global aluminium extrusion market is projected to reach USD 100.18 billion by 2025, driven by the lightweight, corrosion-resistant, and flexible nature of aluminium profiles. With diverse applications, the selection of an appropriate extrusion profile can significantly impact the overall performance, aesthetic appeal, and cost-efficiency of a project. Understanding the various characteristics and requirements of different Aluminium Extrusion Profiles is essential for engineers and designers to make informed decisions that align with their project goals. As we delve into this guide, we will explore the key factors to consider when choosing the right profile for your next venture.

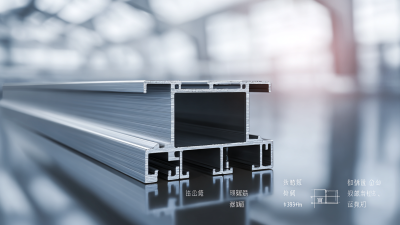

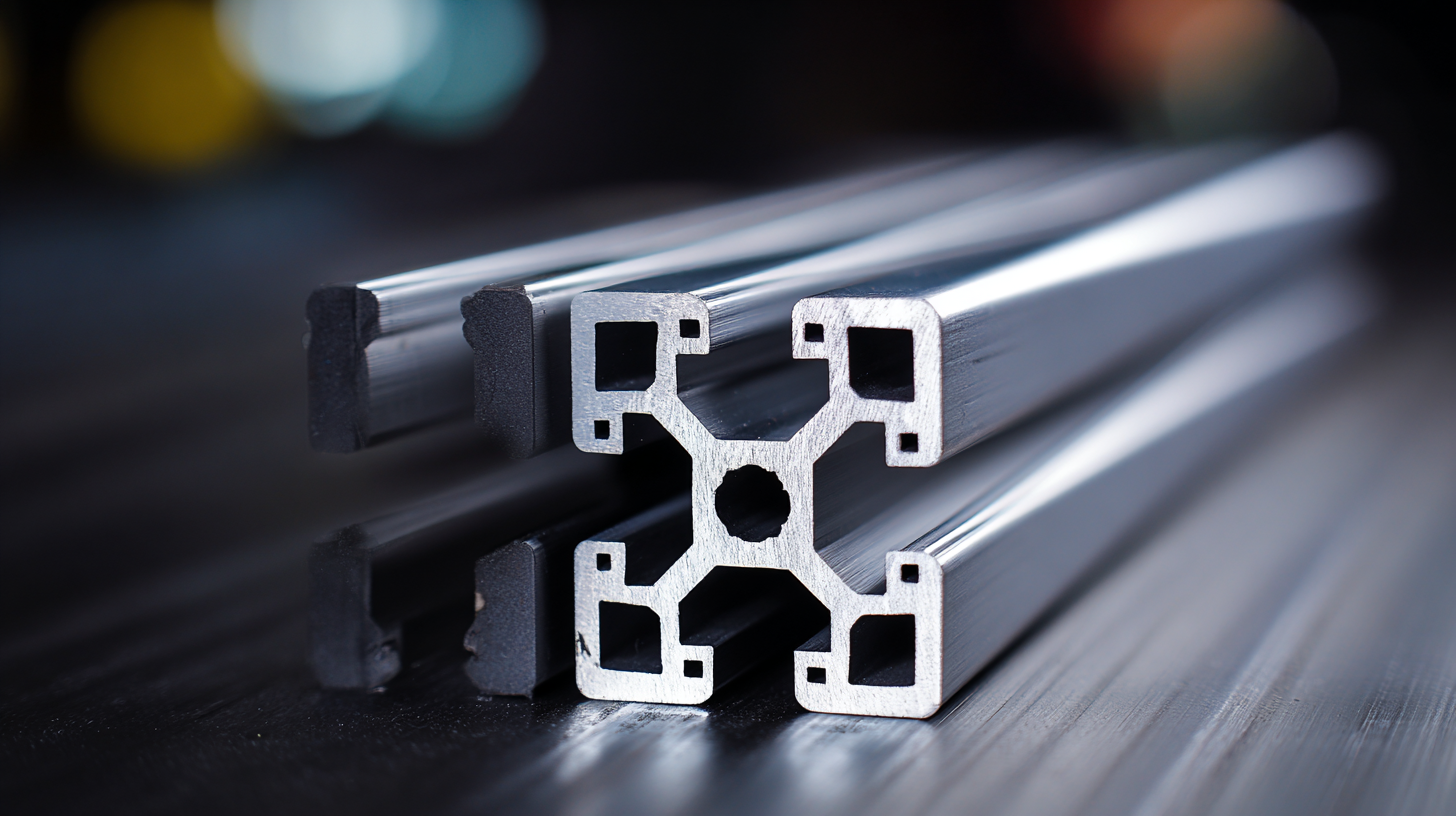

When selecting the right aluminium extrusion profile for your project, it's crucial to understand the fundamentals of aluminium extrusion. The extrusion process involves heating aluminium up to a specific temperature range, typically between 300 and 600 degrees Fahrenheit. This temperature range is essential for ensuring that the aluminium can flow smoothly through the die, which shapes it into the desired profile. However, determining the ideal melt temperature can be nuanced, as it varies depending on the specific alloy and intended application.

Another key consideration is the physical properties of the material you select. The quality of the aluminium alloy can significantly impact the strength, durability, and overall performance of the extruded profile. For projects requiring high precision or specific design features, it's important to review material specifications and ensure compliance with industry standards. Furthermore, understanding factors such as die gap and the potential for contamination can aid in maintaining product integrity during production. By focusing on these fundamental aspects, you can make informed choices that lead to a successful outcome for your project.

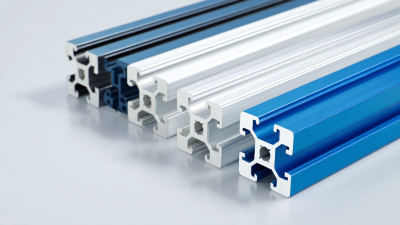

When selecting the right aluminium extrusion profile for your project, several key factors come into play. First and foremost, understanding the specific requirements of your application is crucial. Consider the mechanical properties needed, such as tensile strength, corrosion resistance, and weight. Different aluminium alloys offer varying characteristics, so it’s essential to choose an extrusion that aligns with the demands of your project. For instance, if you need a lightweight and durable solution, alloys like 6061 or 6063 may be ideal due to their balance of strength and workability.

When selecting the right aluminium extrusion profile for your project, several key factors come into play. First and foremost, understanding the specific requirements of your application is crucial. Consider the mechanical properties needed, such as tensile strength, corrosion resistance, and weight. Different aluminium alloys offer varying characteristics, so it’s essential to choose an extrusion that aligns with the demands of your project. For instance, if you need a lightweight and durable solution, alloys like 6061 or 6063 may be ideal due to their balance of strength and workability.

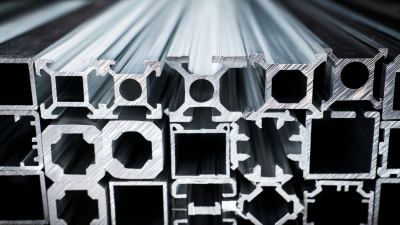

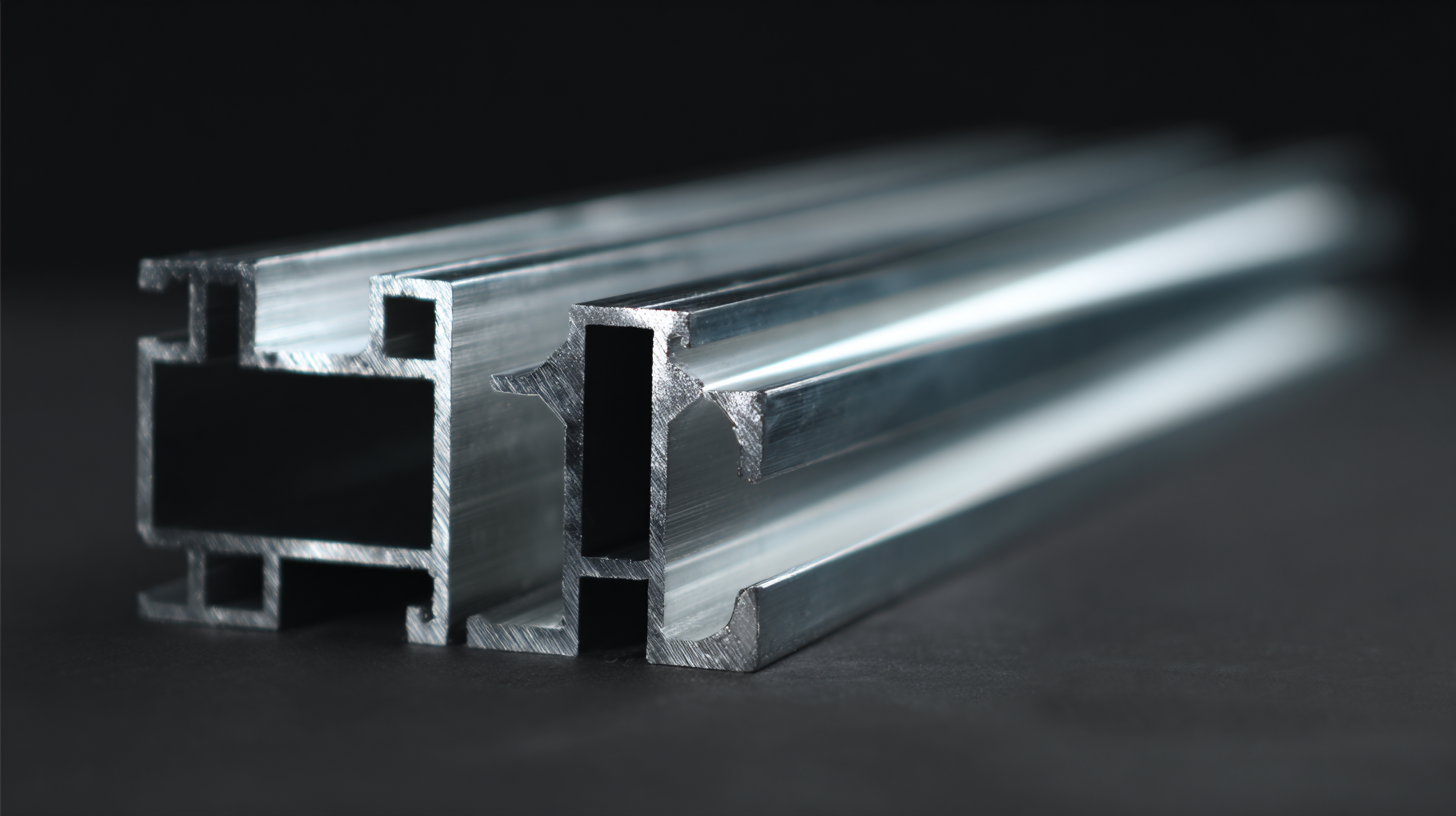

Another significant factor is the complexity of the extrusion shape. Depending on your design, you may have to choose between standard profiles or custom shapes. Standard profiles are often more cost-effective and readily available, making them a practical choice for many applications. However, if your project requires a unique design for improved functionality or aesthetics, custom extrusions may be necessary. It's important to collaborate with your extrusion supplier to determine the feasibility of your desired shapes and to ensure that the extrusion process aligns with your project's timeline and budget.

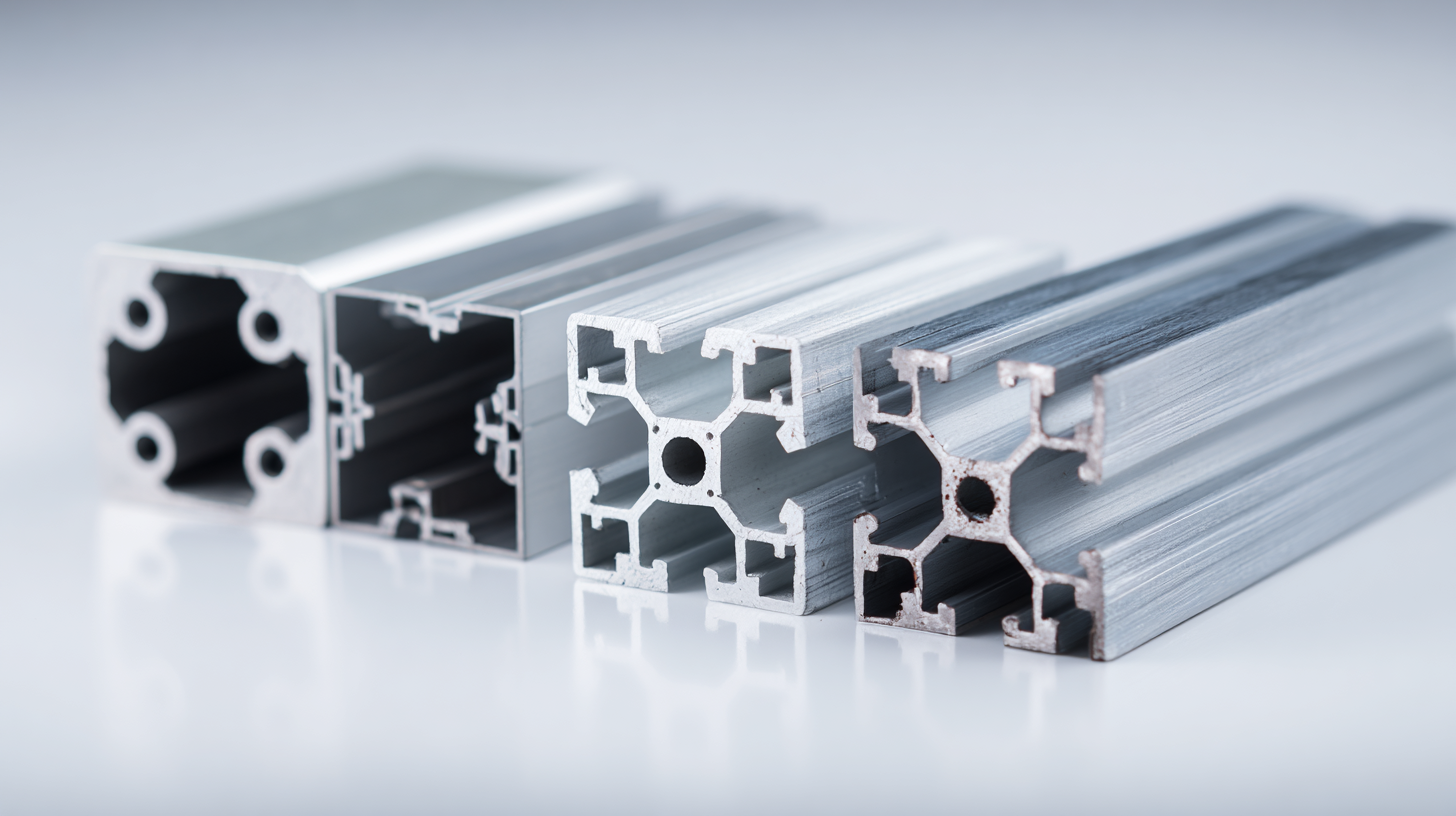

When it comes to selecting the right aluminium extrusion profile for your project, understanding the common applications associated with different profiles is crucial. For instance, architectural profiles, which typically feature intricate designs, are widely used in building facades and window frames. Their aesthetic appeal combined with structural integrity makes them a popular choice for both modern and traditional buildings. In contrast, standard structural profiles, such as I-beams and T-slots, are commonly used in fabrication and manufacturing, providing robustness and ease of assembly for frames, supports, and custom machinery.

Moreover, specialty profiles tailored for specific projects can enhance functionality and performance. Heat sinks, designed to dissipate heat in electrical components, are vital in the electronics industry, ensuring optimal performance and longevity of devices. Meanwhile, automotive profiles are engineered for lightweight yet durable components, contributing to better fuel efficiency and improved vehicle performance. By aligning the correct aluminium extrusion profile with your project requirements, you can maximize both performance and efficiency, ensuring successful outcomes in various applications.

When deciding between standard and custom aluminium extrusions for your project, it’s essential to weigh the benefits of each option carefully. Standard aluminium profiles are typically cost-effective and widely available, which can expedite production times. For instance, industry reports indicate that using standard profiles can reduce lead times by up to 50%, making them a suitable choice for projects with tight deadlines. However, these profiles may not perfectly meet specific design needs or dimensional requirements, leading to potential compromises in functionality.

On the other hand, custom aluminium extrusions allow for greater design flexibility and can be tailored to fit specific applications. According to the Aluminium Association, nearly 60% of projects that utilize custom extrusions benefit from enhanced performance due to optimized designs. While the upfront costs of custom solutions may be higher, they often provide long-term advantages in durability and efficiency.

**Tip 1:** Always conduct a thorough analysis of your project requirements before choosing between standard and custom profiles; assess factors like weight, strength, and thermal properties to make an informed decision.

**Tip 2:** Don’t overlook the significance of supplier expertise. Collaborating with experienced manufacturers can yield insights on design innovations that can save time and costs in the long run.

This chart compares the cost, lead time, and versatility of standard and custom aluminium extrusion profiles, helping you choose the right option for your project.

When selecting the right aluminium extrusion profile for your project, it's crucial to evaluate several important features. One of the primary considerations is the alloy composition, as different alloys offer varying levels of strength, corrosion resistance, and malleability. For instance, according to the Aluminum Association, the 6061 alloy, known for its excellent mechanical properties and weldability, is frequently used in structural applications, while 6063 is preferred for architectural purposes due to its smooth finish and varied shapes. Selecting the appropriate alloy is essential for ensuring that the final product meets both performance and aesthetic requirements.

Another critical feature to evaluate is the profile geometry. Complex shapes can enhance the design flexibility and functionality of your project, but it's important to consider the manufacturing capabilities. A study by the Institute of Metal Research highlights that intricate geometries can increase production costs and lead times, so balancing complexity with practicality is vital. Additionally, assessing the finish of the profile, whether anodized or powder-coated, can significantly impact durability and maintenance. Anodizing, for example, is reported to improve corrosion resistance by up to 30% compared to untreated aluminium, making it a valuable choice for outdoor applications.