In today's competitive manufacturing landscape, the selection of materials for product design plays a pivotal role in determining performance and longevity. One of the most sought-after options for a multitude of applications is Aluminum Handle Extrusions, known for their exceptional strength-to-weight ratio, corrosion resistance, and versatility. According to a report by Grand View Research, the global aluminum extrusion market is expected to reach USD 58.79 billion by 2025, driven by increasing demand across various sectors, including automotive, construction, and industrial applications. With a rising focus on sustainability, manufacturers are also capitalizing on aluminum's recyclability, which reinforces its appeal as an environmentally friendly choice.

This blog will delve into the benefits of Aluminum Handle Extrusions and provide guidance on how to select the right options tailored to your project's specific requirements.

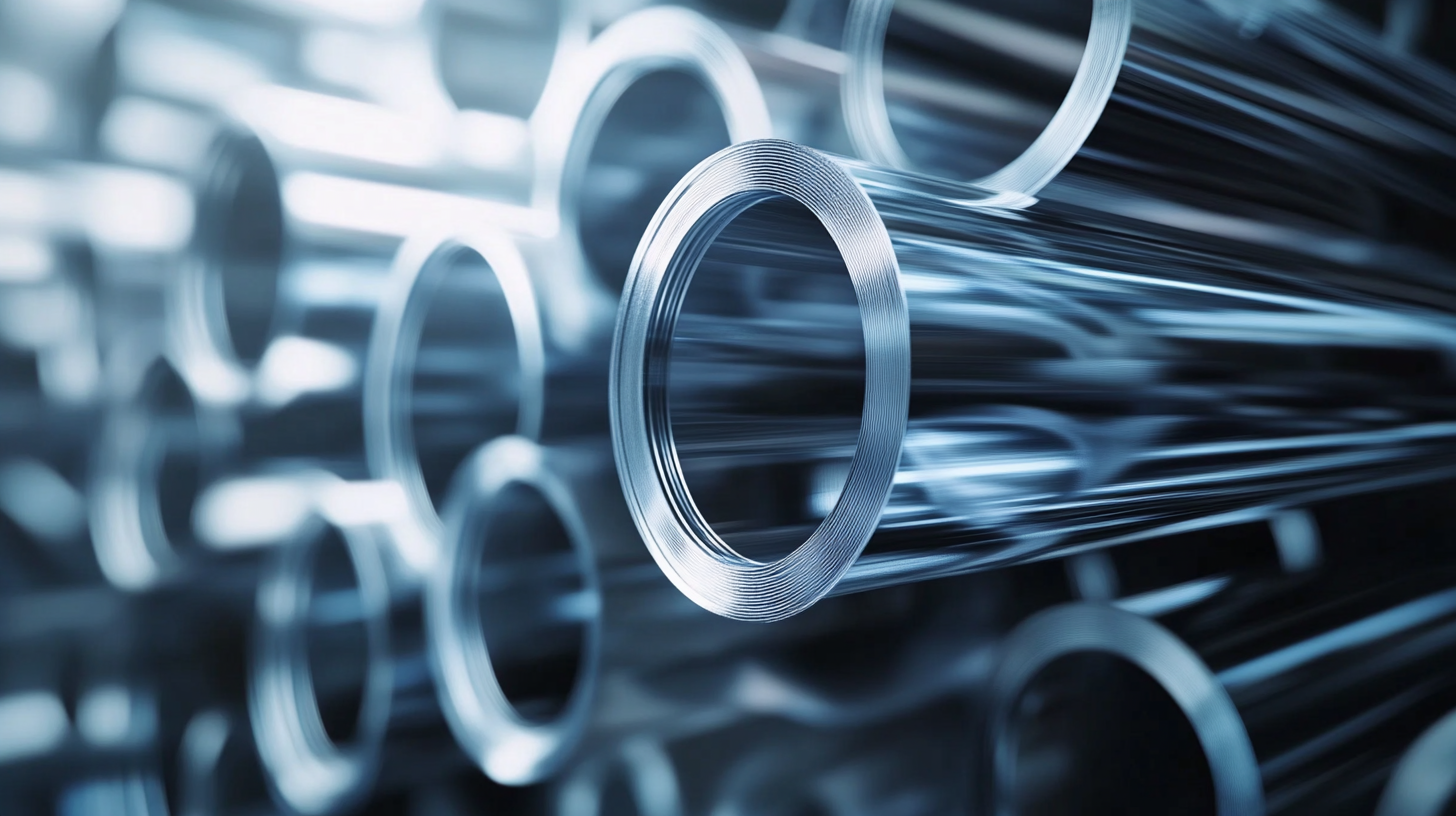

Aluminum handle extrusions offer a range of benefits that make them an ideal choice for various projects. One of the primary advantages of aluminum is its lightweight nature, which makes it easy to handle and install without compromising strength. This is particularly important in projects where weight considerations are paramount, such as in automotive applications or portable devices. Additionally, aluminum's inherent corrosion resistance ensures that the handle extrusions maintain their durability and appearance over time, even in harsh environments.

Another key benefit of aluminum handle extrusions is their versatility in design. Aluminum can be easily extruded into complex shapes, allowing for customized solutions that meet specific project requirements. This adaptability not only enhances aesthetic appeal but also allows for ergonomic designs that improve user experience. Furthermore, aluminum finishes can be tailored, whether through anodizing, painting, or coating, to match various styles and preferences, making it a perfect choice for both functional and decorative applications.

When selecting aluminum handle extrusions for your project, several key factors should be taken into consideration to ensure optimum functionality and durability. First and foremost, the type of project will influence the specific design requirements of the extrusions. According to a recent report by the IMARC Group regarding aluminum extrusion manufacturing, understanding the differences between standard, modified, and custom extrusions is crucial. This knowledge helps in determining the right specifications that will meet both aesthetic and structural standards in various applications.

Another important factor is the cost of production and materials. The same report highlights the significance of budgeting for the setup of an aluminum extrusion factory, as well as estimating the costs associated with custom designs. Investing in high-quality materials may lead to higher initial costs, but it often results in long-term savings through enhanced durability and reduced maintenance needs. Finally, consideration of the extrusion's compatibility with existing frameworks and its performance under various environmental conditions will ultimately determine its suitability for commercial applications, particularly for aluminum swinging doors and frames. Understanding these nuances will guide you in making informed decisions that align with your project goals.

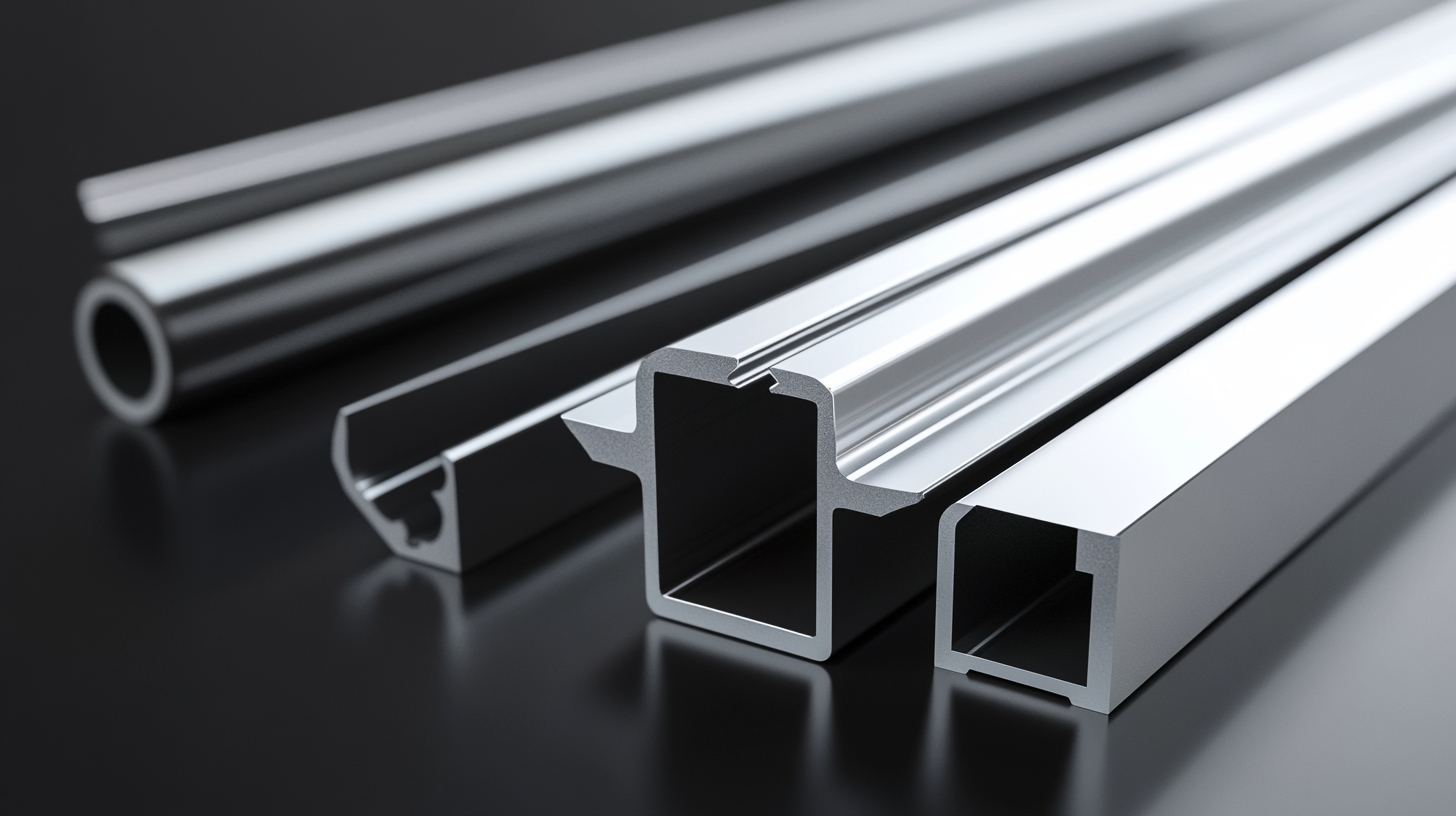

When selecting aluminum handle extrusions for your project, it's crucial to consider the specific type that best suits your application. Here are the top five types to consider. First, ergonomic handles are designed for comfort and ease of use, making them ideal for kitchen appliances and tools. These handles often feature a contoured shape that reduces user fatigue during prolonged use.

Secondly, the industrial-grade extrusions are perfect for heavy-duty applications. Their strength and durability make them suitable for machinery and equipment where reliability is paramount. Another option is decorative handles, which not only serve a functional purpose but also enhance aesthetic appeal. These are commonly used in furniture and cabinetry, allowing for a blend of style and utility.

Lastly, adjustable handles offer versatility for various tasks and users, making them popular in portable devices or multi-use tools. Lastly, T-slot extrusions provide the flexibility to create custom mounting solutions for different designs. By understanding these types of aluminum handle extrusions, you can select the best option tailored to the demands of your project.

When selecting aluminum handle extrusions for your project, it's crucial to avoid common pitfalls that could lead to frustration and wasted resources. One common mistake is overlooking the specifications of the extrusion. Each project has unique requirements, whether it’s the size, thickness, or finish of the handle. Failing to align these specifications with the functional needs of your product can result in handles that don’t fit properly or do not perform well under stress.

When selecting aluminum handle extrusions for your project, it's crucial to avoid common pitfalls that could lead to frustration and wasted resources. One common mistake is overlooking the specifications of the extrusion. Each project has unique requirements, whether it’s the size, thickness, or finish of the handle. Failing to align these specifications with the functional needs of your product can result in handles that don’t fit properly or do not perform well under stress.

Another frequent error is neglecting the importance of supplier reputation. Not all aluminum extrusions are created equal, and quality varies between manufacturers. Research suppliers thoroughly; look for those who provide detailed product information and have a track record of reliability. Cheaper options might seem tempting, but they can compromise the integrity of your project.

Tip: Always request samples before committing to a large order. This allows you to evaluate the material and design firsthand, ensuring it meets your expectations. Additionally, consider the intended use of the handle—whether it needs to withstand heavy loads or resist corrosion, as this will guide you in choosing the right aluminum alloy for your needs.

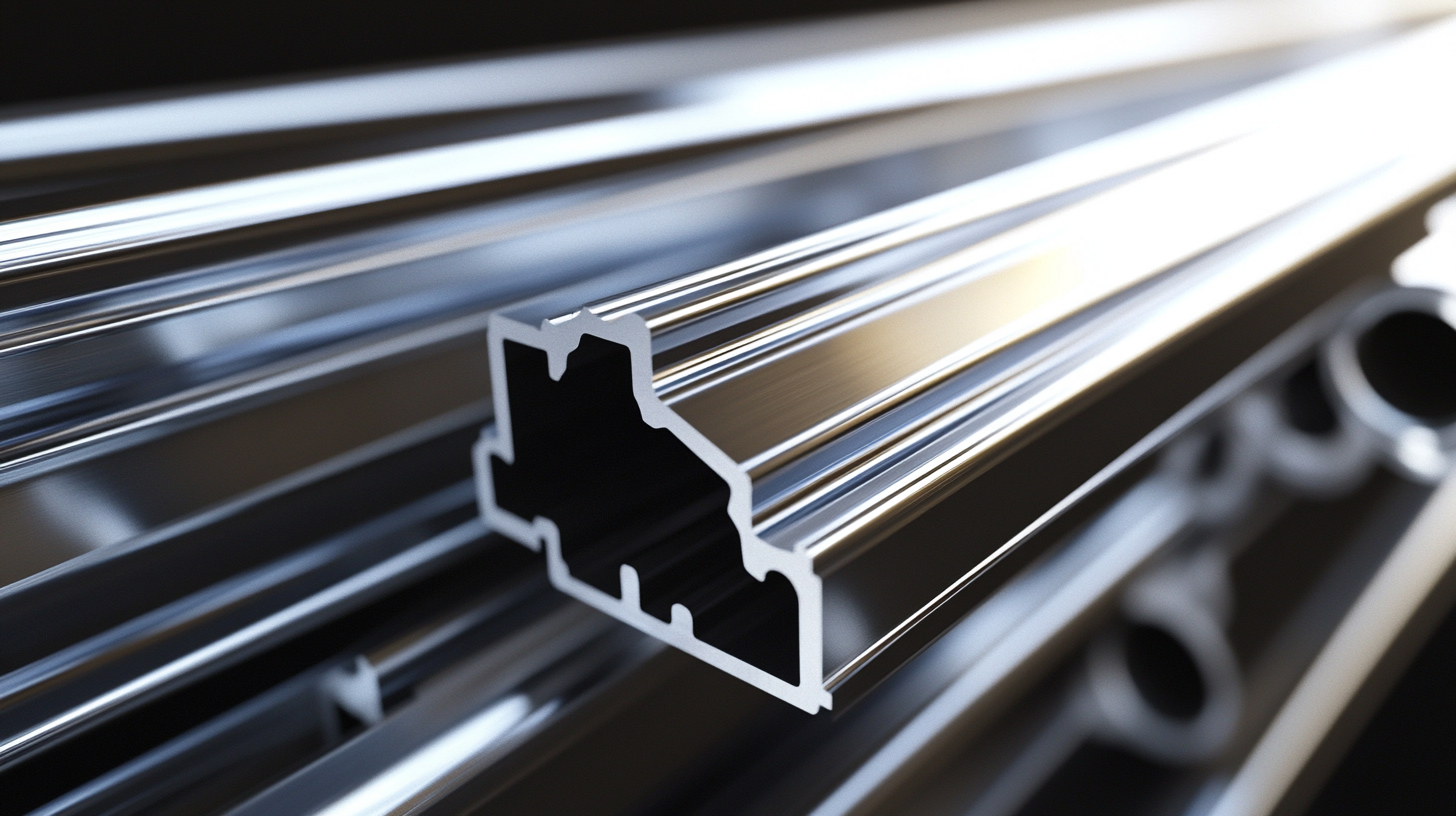

When selecting aluminum handle extrusions for your project, assessing quality is paramount. A key factor to consider is the alloy type; for instance, 6061 and 6063 aluminum alloys are popular choices due to their excellent corrosion resistance and weldability. According to a recent industry report by the Aluminum Association, components made from these alloys can exhibit tensile strengths from 20,000 to 40,000 psi, making them suitable for a variety of applications, from consumer products to industrial machinery.

Another important aspect of quality assessment is the surface finish. Anodized finishes are often recommended for their durability and aesthetic appeal. Data from the National Association of Architectural Metal Manufacturers indicates that anodized aluminum can maintain its appearance over time, resisting degradation from UV exposure and harsh environmental conditions. Additionally, ensure that any extrusion you choose passes industry standards such as ISO 9001, which guarantees that the product meets rigorous quality management principles, thereby minimizing defects and enhancing usability in your project.

| Dimension (mm) | Weight (kg/m) | Strength (MPa) | Finish Quality | Corrosion Resistance |

|---|---|---|---|---|

| 20 x 20 | 0.75 | 250 | Excellent | High |

| 25 x 25 | 1.00 | 270 | Very Good | Moderate |

| 30 x 30 | 1.25 | 300 | Good | High |

| 40 x 40 | 1.50 | 320 | Excellent | Very High |