In the ever-evolving construction and manufacturing industries, selecting the right materials is crucial for the success of any project.

Aluminum L Shape Angle, known for its lightweight yet durable properties, has become increasingly popular in various applications,

from structural supports to aesthetic architectural details.

According to a recent report by Grand View Research, the global aluminum market is projected to reach USD 245.73 billion by 2025, with significant contributions from the construction sector,

which drives the demand for versatile components like Aluminum L Shape Angles.

As professionals navigate the complexities of material selection, understanding the specifications and applications of Aluminum L Shape Angles not only enhances structural integrity

but also optimizes project efficiency and sustainability.

This guide will provide you with essential insights on how to make informed choices when integrating Aluminum L Shape Angles into your next project,

ensuring that you capitalize on their unique benefits.

Aluminum L Shape Angle, known for its lightweight yet durable properties, has become increasingly popular in various applications,

from structural supports to aesthetic architectural details.

According to a recent report by Grand View Research, the global aluminum market is projected to reach USD 245.73 billion by 2025, with significant contributions from the construction sector,

which drives the demand for versatile components like Aluminum L Shape Angles.

As professionals navigate the complexities of material selection, understanding the specifications and applications of Aluminum L Shape Angles not only enhances structural integrity

but also optimizes project efficiency and sustainability.

This guide will provide you with essential insights on how to make informed choices when integrating Aluminum L Shape Angles into your next project,

ensuring that you capitalize on their unique benefits.

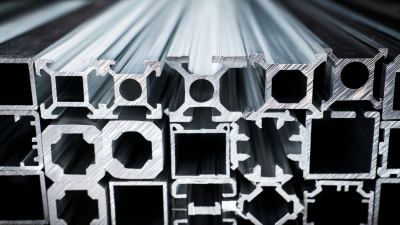

When selecting the right aluminum L shape angle for your project, it's essential to understand the various types available. Aluminum L shape angles can be made from different grades of aluminum, which impacts their strength, weight, and corrosion resistance. Common options include 6061 and 6063, with 6061 being more robust and suitable for structural applications, while 6063 is often preferred for aesthetic purposes, such as architectural frames.

Tips: Always consider the application when choosing your aluminum angle. For heavy-duty structures, opt for thicker and stronger profiles, while for light-duty applications, standard sizes should suffice. Additionally, pay attention to the finish, as anodized aluminum can provide added protection against environmental factors.

Furthermore, the length and thickness of the L shape angle are crucial factors to consider. Standard lengths are readily available, but custom sizes can also be ordered if necessary. Ensure you measure your project requirements accurately to avoid excess waste or the need for additional materials. Selecting the right specifications will not only enhance the durability of your project but also ensure a clean and professional finish.

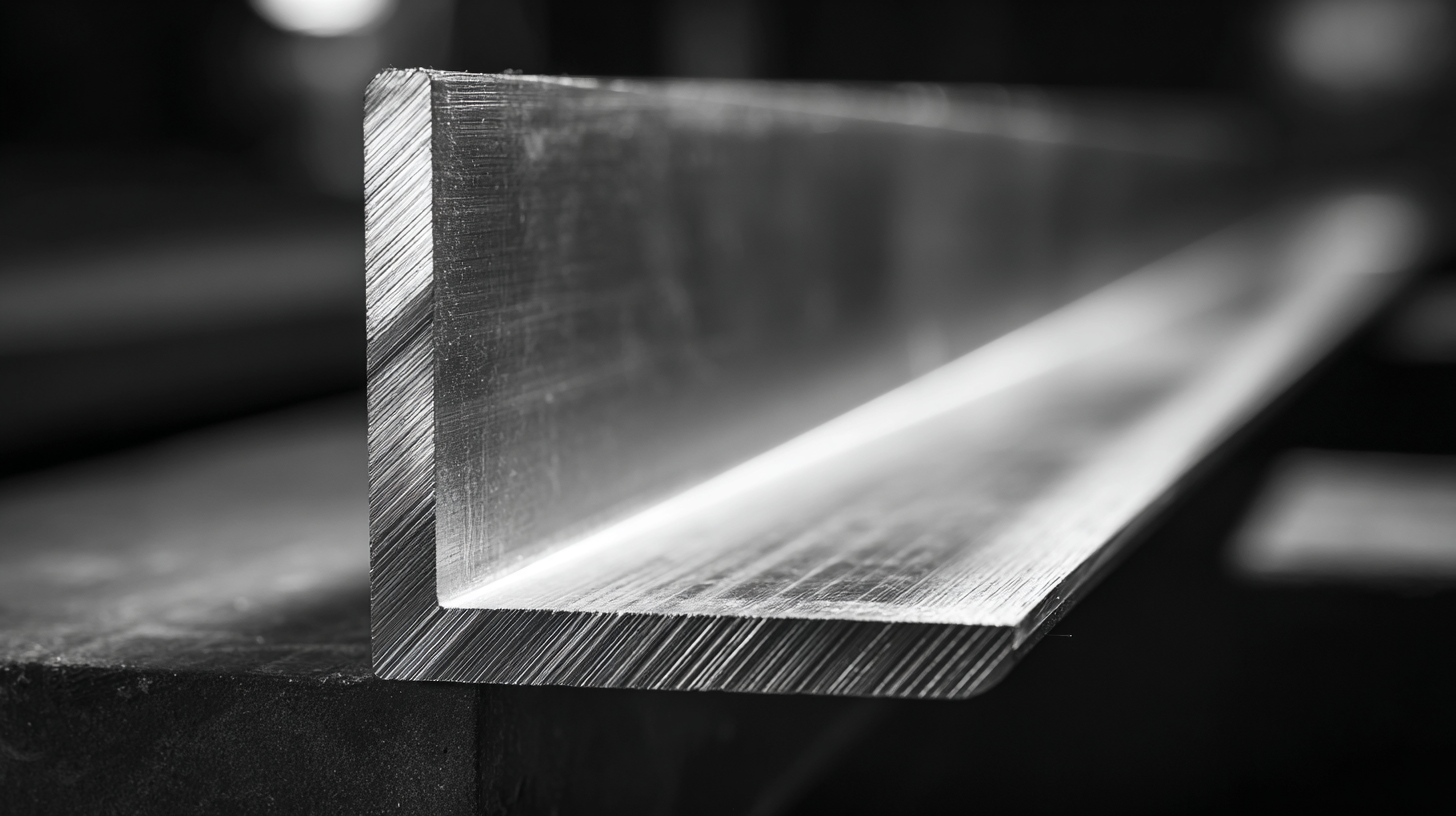

When selecting the right aluminum L shape angle for your next project, several key factors should be considered to ensure durability and suitability for your specific needs. First and foremost, the size and dimensions of the angle are crucial. Consider the thickness and length required for your project, as this will directly impact the strength and stability of the assembly. It's important to measure your space accurately and account for any weight that the angle will support.

Another critical factor is the alloy composition of the aluminum. Different alloys offer varying levels of strength, corrosion resistance, and weldability. For outdoor applications, aluminum with higher resistance to oxidation might be necessary to extend the lifespan of your project. Additionally, consider the finish of the aluminum, as an anodized surface can provide extra protection and improve aesthetics.

Tips: When shopping for aluminum L shape angles, always check for certifications that guarantee quality and compliance with industry standards. Furthermore, consulting with experts or suppliers can provide insights into the best options available, ensuring that you make an informed decision. Lastly, don't forget to consider the cost-effectiveness of the material while balancing quality and performance.

This chart displays key factors to consider when selecting aluminum L shape angles, including thickness, length, weight per meter, load capacity, and cost. Each factor is crucial in determining the best angle for your specific project needs.

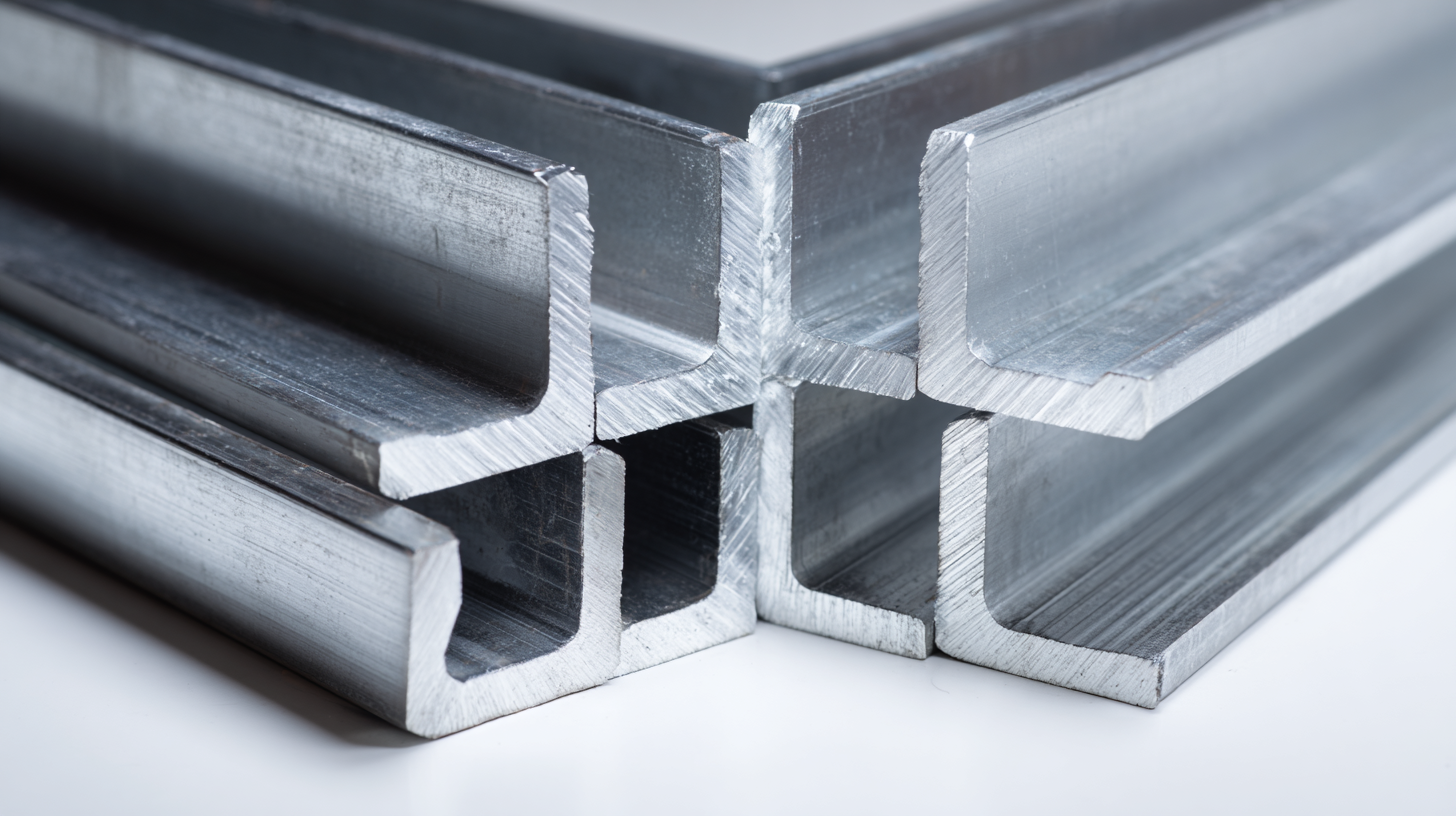

When selecting the right aluminum L shape angle for your project, one of the most critical factors to consider is the load-bearing requirements. Understanding the types of loads that the angle will support—whether static or dynamic—helps in determining the appropriate size and thickness. Static loads are consistent, such as a stationary table, while dynamic loads fluctuate, like machinery vibrations. Evaluating the force exerted on the angle during usage is essential for safety and structural integrity.

Additionally, it’s vital to consider the material properties of aluminum, such as its tensile strength and corrosion resistance. Different aluminum alloys possess varying load-bearing capacities, which can significantly influence your selection. For outdoor projects or those exposed to moisture, opting for a corrosion-resistant alloy ensures longevity and reliability. Always calculate the maximum anticipated load and choose an L shape angle that provides a safety margin to account for unexpected stresses or usage variations, ensuring your project’s success.

| Angle Size (inches) | Thickness (mm) | Maximum Load Capacity (lbs) | Material Specification | Application Examples |

|---|---|---|---|---|

| 1 x 1 | 3 | 200 | 6061-T6 | Furniture Frames, Brackets |

| 2 x 2 | 4 | 400 | 6063-T5 | Railings, Support Structures |

| 3 x 3 | 5 | 600 | 7075-T6 | Heavy Machinery, Structural Components |

| 1.5 x 1.5 | 3 | 250 | 6061-T6 | Shelving Units, Trusses |

| 4 x 4 | 6 | 800 | 7075-T6 | Construction Frames, Equipment Stands |

When selecting the right aluminum L shape angle for your project, evaluating surface finishes and corrosion resistance options is critical for ensuring longevity and performance. Aluminum naturally offers excellent corrosion resistance; however, this can be enhanced through various surface treatments. According to a report from the Aluminum Association, up to 80% of aluminum's surface can endure corrosion without any treatment, but methods such as anodizing can significantly increase this resistance, providing a protective layer that can withstand harsh environments.

Anodizing, especially hardcoat anodizing, adds an additional layer of protection against wear and corrosion, making it ideal for applications in marine or chemical environments. A study published by the Journal of Manufacturing Processes indicated that components with anodized finishes exhibited a 30% increase in corrosion resistance compared to their untreated counterparts. Furthermore, powder coating is another surface finish option that not only enhances aesthetics but also provides extra protection. A research paper from the American Coatings Association states that powder coating can double the lifespan of aluminum components exposed to extreme weather conditions, making it a compelling choice for exterior applications.

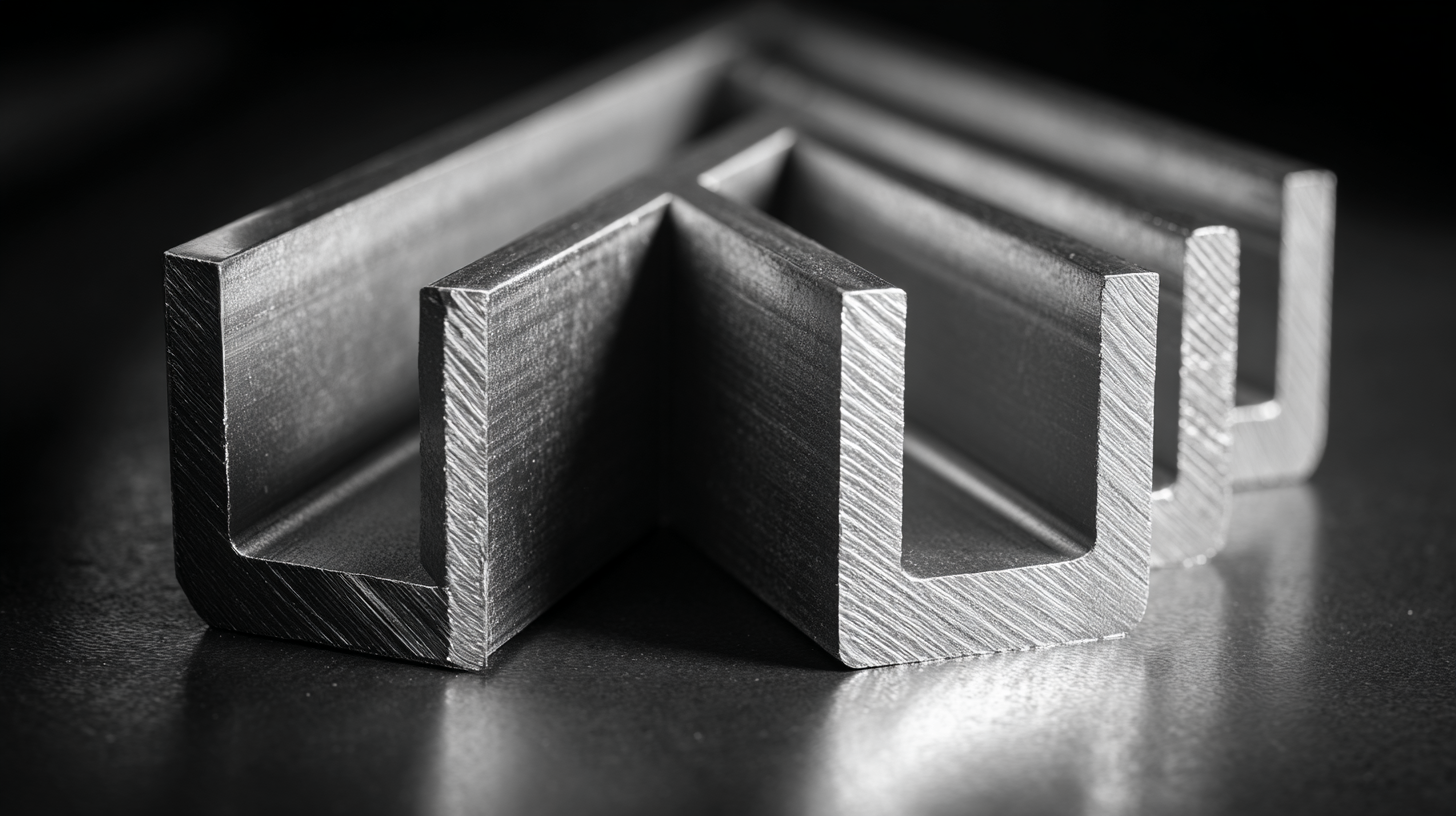

When selecting an aluminum L shape angle for your project, calculating the cost-effectiveness is paramount. Start by assessing the specific requirements of your project, including the size, weight-bearing capacity, and environmental factors. Different grades of aluminum can vary significantly in price, so understanding the demands of your project helps in narrowing down the options. For instance, while a higher-grade aluminum alloy may be more expensive, its durability and resistance to corrosion can lead to lower maintenance costs over time.

Next, consider the quantity needed and how bulk purchasing might affect overall costs. Many suppliers offer discounts for larger orders, which can enhance your project's cost-effectiveness. Don't forget to factor in the potential expense of fabrication and installation, as some L shape angles may require additional processing that could increase costs. By evaluating both material selection and associated expenses, you can choose an aluminum L shape angle that not only meets your project's requirements but also maximizes your budget efficiency.