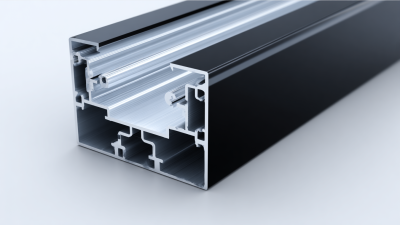

The demand for aesthetically appealing yet durable materials in construction and design has spurred the popularity of Wood Grain Aluminum Tube, which combines the visual warmth of wood with the resilience of aluminum. According to a recent industry report from Grand View Research, the global aluminum extrusion market is projected to reach USD 176.5 billion by 2026, highlighting a growing inclination towards innovative materials in various applications, including architectural elements and furniture design. Wood Grain Aluminum Tubes stand out not only for their striking appearance but also for their low maintenance and high durability. As professionals seek to enhance their projects with this versatile material, understanding effective techniques to maximize its potential becomes essential. In this blog, we will explore five effective tips that can help you elevate your Wood Grain Aluminum Tube projects, ensuring they are both visually stunning and structurally sound.

Wood grain aluminum tubes have become increasingly popular in various design projects, offering the aesthetic appeal of wood while maintaining the durability of metal. Understanding the basics of these materials is crucial for anyone looking to enhance their projects. According to recent market research, the decorative aluminum segment, which includes wood grain finishes, is expected to grow significantly, with a projected CAGR of 5.3% through 2026. This trend indicates a strong preference among consumers for versatile and visually striking materials that can mimic the look of natural wood.

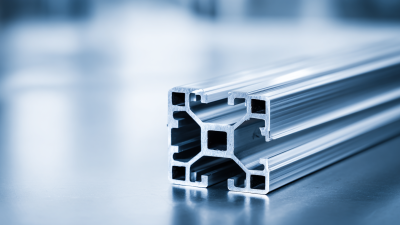

Equipping your workspace with the right tools is essential for working effectively with wood grain aluminum tubes. Specific tools like routers and specialized bits can greatly enhance the precision of cuts and the quality of joints, making your projects more efficient. In addition, having access to essential restoration tools can further broaden your capabilities, especially when it comes to integrating these tubes into furniture designs or refurbishing existing pieces. Trends indicate that well-equipped workshops, featuring multipurpose tools, significantly reduce project turnaround times, allowing creators to focus more on design than on labor-intensive processes.

When diving into wood grain finishing for aluminum tube projects, selecting the right tools and materials can dramatically influence the outcome. One essential tip is to invest in high-quality wood grain applicators. These tools not only provide precision but also help achieve a more realistic grain effect. Look for applicators designed specifically for aluminum surfaces to ensure optimal adhesion and finish.

Another critical factor is the choice of finishing materials. Opt for water-based finishes that are both environmentally friendly and easy to clean up. These finishes allow for a smoother application while enhancing the wood grain look. Be sure to test different shades on scrap metal to find the perfect match for your project before committing to the final application. This experimentation phase can save time and materials in the long run.

Finally, don't overlook the importance of preparation. Start with a well-cleaned and primed surface to ensure that your wood grain finish adheres properly. Investing time in surface prep can make a significant difference in the durability and appearance of your finished project.

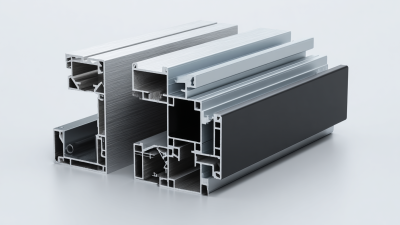

Achieving a realistic wood grain effect on aluminum surfaces can significantly enhance the aesthetic appeal of any project. Various techniques have emerged in the industry, supported by data from the Coatings Industry Association, which reveals that over 60% of consumers prefer finishes that mimic natural materials like wood.

For instance, the use of digital printing technology has transformed how we apply wood grain designs, allowing for intricate and highly detailed patterns that can be reproduced consistently. These techniques not only provide a striking appearance but also offer durability that surpasses traditional wood finishes.

Another effective method involves the application of specialized wood grain transfer films, which have been shown to maintain their visual quality over extended periods. According to a recent market analysis by Smithers Pira, the global demand for wood grain finishes in metal products is projected to grow at a rate of 5.7% annually through 2025. This trend underscores the importance of mastering wood grain techniques for manufacturers seeking to remain competitive. By leveraging these innovative methods, artisans and manufacturers can create visually stunning aluminum tube projects that stand out in a crowded marketplace while catering to consumer preferences for organic aesthetics.

When working with wood grain aluminum projects, protecting and maintaining the finish is essential to ensure their longevity and aesthetic appeal. One of the most crucial tips is to regularly clean your pieces using a soft cloth and a gentle cleanser. This will help remove dirt and grime that can accumulate over time, potentially dulling the wood grain effect. Additionally, consider applying a protective sealant specifically designed for aluminum surfaces. This not only shields the material from environmental elements but also enhances its color vibrancy.

Furthermore, for projects exposed to outdoor conditions, such as patio furniture, weatherproofing strategies are vital. Using furniture covers can protect against rain and UV damage, while storing items indoors during harsh weather can significantly extend their lifespan. Regularly checking for signs of wear and tear allows you to address issues early on, keeping your aluminum projects looking fresh and new. By staying proactive with maintenance and protective measures, you can enjoy the beauty of your wood grain aluminum pieces for years to come.

| Tip | Description | Benefits |

|---|---|---|

| Choose Quality Materials | Select high-grade wood grain aluminum tubes for durability. | Increased longevity and resistance to wear and tear. |

| Proper Surface Preparation | Clean and sand surfaces before applying finishes. | Better adhesion of coatings and paints. |

| Use Protective Coatings | Apply a clear sealant to protect the finish. | Prevents fading and damage from environmental factors. |

| Regular Maintenance | Inspect and clean your projects regularly to prolong their life. | Ensures sustained aesthetics and functionality. |

| Storage Considerations | Store items in controlled environments away from extreme weather. | Maintains structural integrity and appearance. |

Wood grain aluminum tubes represent a unique fusion of aesthetics and practicality, making them a favored choice in modern design and construction projects. According to a report by a leading industry research firm, the global market for aluminum products is projected to reach $160 billion by 2025, with a significant surge in demand for innovative finishes such as wood grain. This trend is driven by the growing consumer interest in alternatives that offer the beauty of natural wood alongside the durability and low maintenance of aluminum. Designers and architects are increasingly adopting these tubes for handrails, furniture, and decorative elements, capitalizing on their ability to blend seamlessly with various materials and styles.

In particular, the application of wood grain aluminum tubes extends beyond mere aesthetics. Their lightweight yet robust nature makes them suitable for structural purposes while reducing overall project costs. As noted in a recent construction materials report, the adoption of aluminum components can lead to a reduction in labor and material costs by up to 25%. Moreover, with advancements in wood grain printing technology, manufacturers can accurately replicate a myriad of wood textures and colors, allowing for greater design flexibility. This versatility is paving the way for innovative architectural solutions, bridging the gap between natural beauty and engineering efficiency in a wide array of projects.