In recent years, the construction and manufacturing industries have increasingly recognized the importance of effective thermal management, particularly in the context of rising energy costs and environmental concerns. According to a report by MarketsandMarkets, the global heat insulation materials market is expected to reach $73.2 billion by 2027, driven by a surge in demand for energy-efficient building solutions.

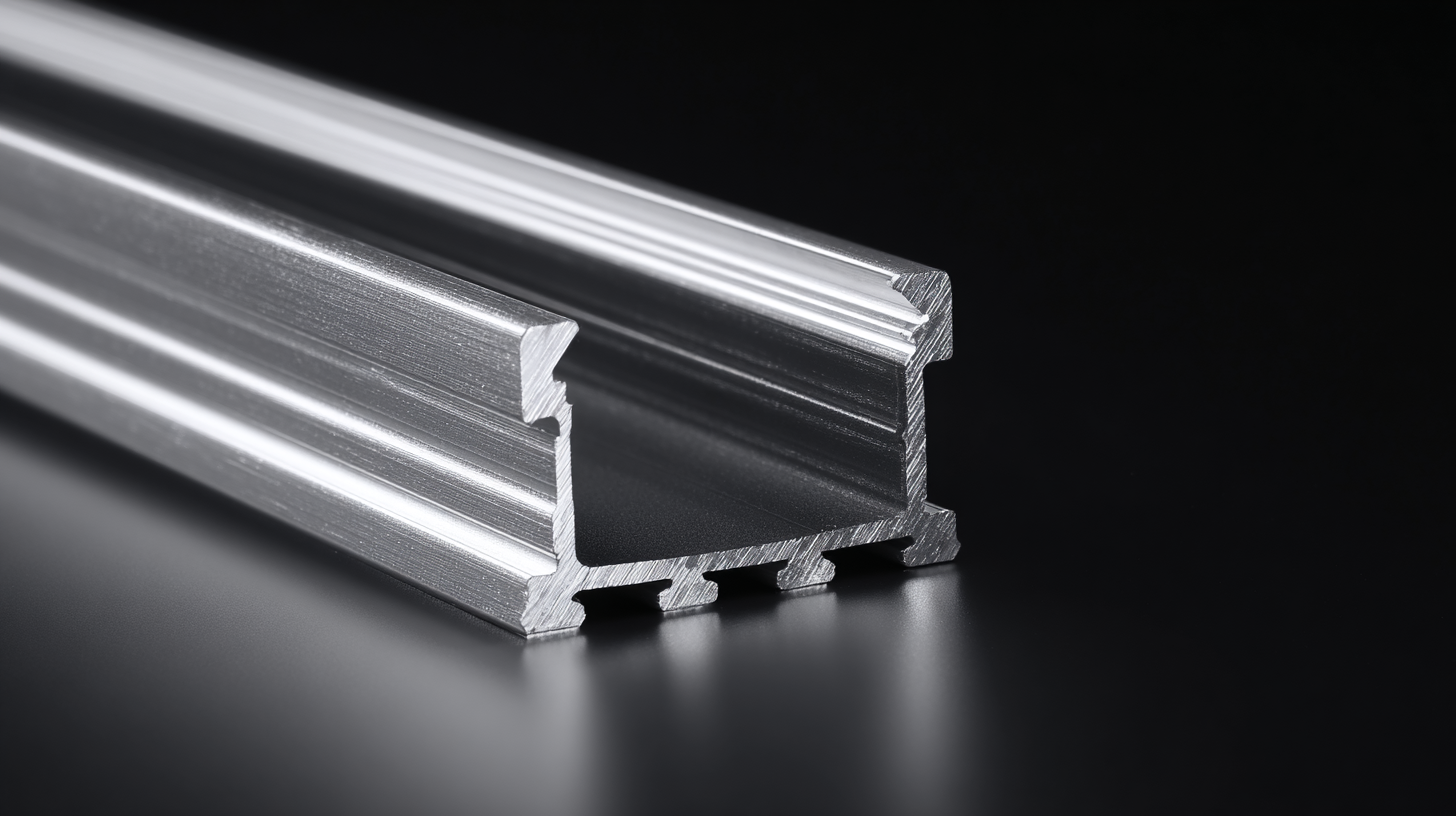

Among these solutions, Heat Insulation Aluminum Profiles have emerged as a preferred choice due to their lightweight properties, durability, and exceptional thermal performance. As architects and builders strive to meet stringent energy efficiency standards, selecting a high-quality manufacturer of these profiles is crucial.

This blog explores innovative alternatives in the market, emphasizing the necessity of comparing different manufacturers to ensure the best selection for project needs, ultimately enhancing energy efficiency and sustainability in construction.

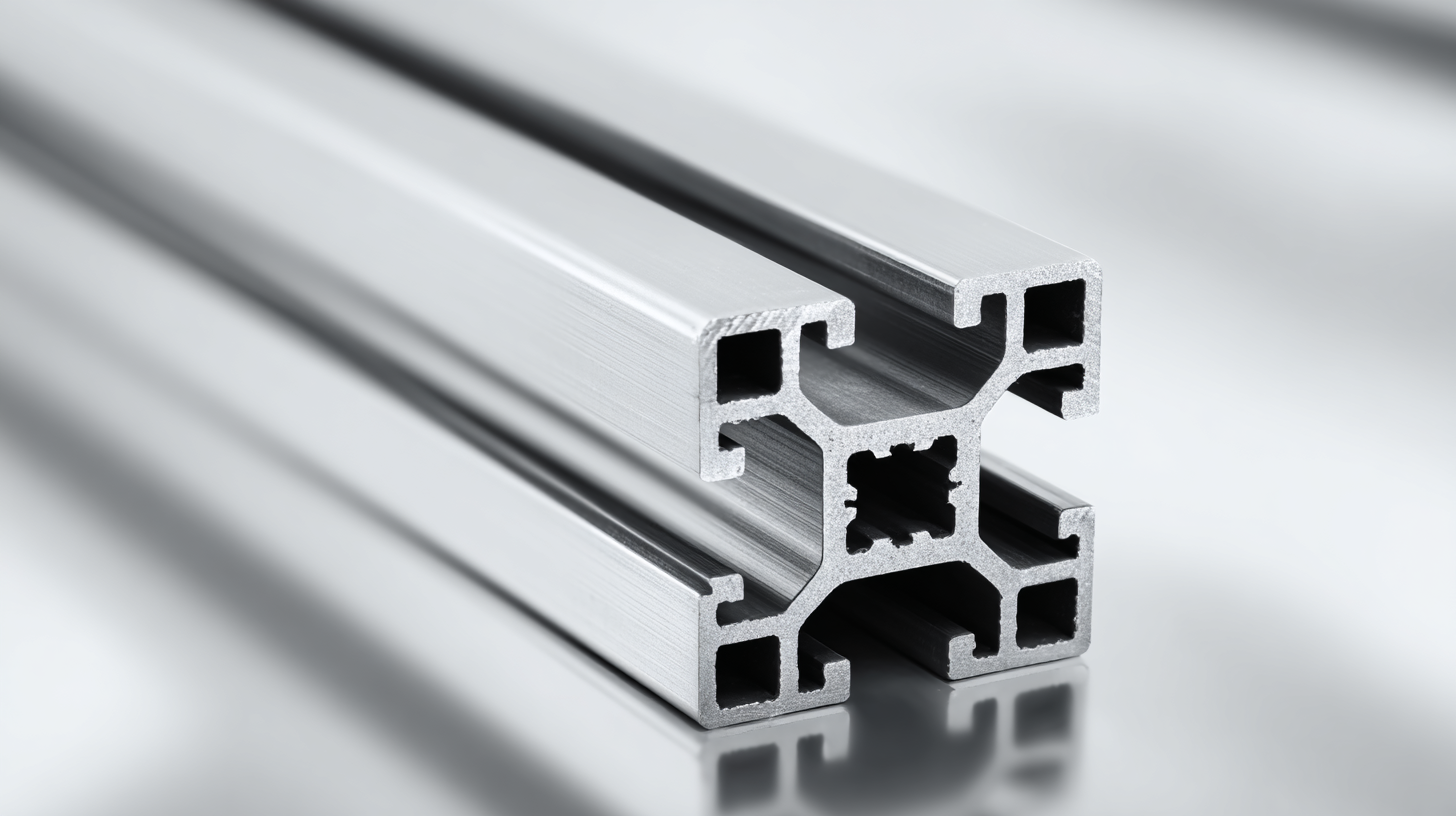

In recent years, the quest for enhanced thermal performance in aluminum profiles has led to the exploration of innovative materials that push the boundaries of traditional heat insulation. While aluminum is known for its strength and lightweight properties, it often falls short in terms of thermal efficiency. To counter this, manufacturers are now integrating advanced polymers and composites into their designs. These materials not only improve heat insulation but also work synergistically with aluminum to create more effective and energy-efficient profiles.

One notable innovation is the use of aerogels, which are incredibly lightweight and possess remarkable insulating properties. By incorporating aerogel layers within aluminum frames, builders can significantly reduce heat transfer, making homes and commercial buildings more energy-efficient. Additionally, the development of hybrid materials, which combine the benefits of both aluminum and insulating polymers, offers exciting prospects. These materials can be tailored for specific applications, improving heat resistance while maintaining the structural integrity of the profile. As the demand for energy-efficient solutions continues to grow, exploring these innovative alternatives promises to revolutionize the industry and set new standards in thermal insulation.

When exploring heat insulation solutions for buildings, a comparative analysis of traditional materials versus innovative alternatives reveals crucial insights into market trends and performance efficacy. The global building insulation materials market is set to grow significantly, driven by the increasing demand for energy-efficient solutions. Traditional insulation methods primarily focus on materials such as fiberglass and foam, which have been widely adopted for their thermal resistance properties. However, as the market evolves, innovative alternatives that offer enhanced energy conservation and sustainability features are gaining traction.

One notable development is the emergence of semi-transparent concrete, an exciting alternative that not only provides insulation but also serves aesthetic purposes. With a growing market projected to reach substantial values by 2033, these materials are pushing the boundaries of what insulation can achieve. Moreover, the introduction of advanced materials like those developed for electric vehicle battery components, which incorporate flame-retardant properties, demonstrates a commitment to safety and performance in insulation technology.

As industries adapt to rising energy costs and regulatory demands, the pursuit of better insulation solutions will undoubtedly continue to shape the construction landscape.

In recent years, the advancement of nano-insulation technologies has profoundly impacted the design of aluminum profiles, offering innovative alternatives for enhanced heat insulation. Traditional insulation methods have limitations in thermal performance and weight, which can hinder energy efficiency in various applications. By integrating nano-fibrillation techniques, researchers are developing highly expanded composite foams that exhibit outstanding thermal insulation properties, proving to be a game changer in aluminum profile applications.

These new composite foams, produced through advanced nano-fibrillation processes, significantly improve insulation without compromising structural integrity. Their microcellular structure allows for a reduction in thermal conductivity while maintaining a lightweight profile. As the demand for sustainable and energy-efficient building materials grows, utilizing these innovative insulation technologies in aluminum profiles can lead to more efficient designs that cater to modern energy standards. Embracing these advancements not only enhances the performance of aluminum structures but also aligns with global sustainability goals.

Sustainability is increasingly becoming a focal point in the building materials industry, particularly in the search for eco-friendly insulation solutions. Traditional aluminum profiles, known for their heat insulation properties, come with a significant carbon footprint. According to a report by the International Energy Agency (IEA), buildings account for 36% of global energy consumption and nearly 40% of CO2 emissions. This pressing issue has sparked the exploration of innovative alternatives that not only provide superior insulation but also align with sustainability goals.

One promising alternative is the use of recycled materials in the production of insulation profiles. For instance, high-density polyethylene (HDPE), made from 100% recycled plastic, is emerging as a viable solution, offering comparable thermal insulation while reducing waste. A study by the Environmental Protection Agency (EPA) highlights that using recycled materials in construction can reduce greenhouse gas emissions by up to 50%. Furthermore, bio-based insulation materials, such as cellulose and sheep's wool, have gained traction due to their natural properties and lower environmental impact, complementing the growing demand for sustainable building practices. By prioritizing these eco-friendly alternatives, the industry can address both energy efficiency and environmental challenges effectively.

As we delve into the future trends of heat insulation, particularly in aluminum applications, it’s essential to recognize the pivotal advancements that are shaping the industry. Recent innovations in materials science have highlighted the potential of cellulose-based aerogel composites, which are gaining traction due to their excellent thermal properties and sustainable sourcing. These composites can enhance the insulation capabilities of aluminum profiles, offering improved performance in energy efficiency and environmental sustainability.

Moreover, the exploration of aluminum as a solid thermal storage medium represents a significant stride forward. Coupled with novel battery thermal management systems, these technologies are being refined to extend energy storage applications in both residential and commercial settings. As the quest for better thermal insulation continues, industry stakeholders are urged to embrace these cutting-edge materials and methods, ensuring optimized solutions for a greener future. The dynamic intersection of these advancements not only promises enhanced thermal insulation but also a more sustainable approach to energy consumption in aluminum construction and beyond.