The aluminum kitchen profiles market is poised for significant transformation, driven by innovative technology and a growing emphasis on sustainability. Recent industry reports indicate that the global aluminum kitchen profiles market is expected to reach USD 6.3 billion by 2027, growing at a CAGR of 4.8% from 2020 to 2027. This growth is fueled by rising consumer demand for lightweight, durable, and aesthetically pleasing kitchen solutions, alongside a shift towards eco-friendly materials.

As manufacturers increasingly harness cutting-edge technologies, such as advanced fabrication techniques and smart design integration, the efficiency and versatility of aluminum kitchen profiles continue to improve. Moreover, a shift in consumer preferences toward sustainable products underscores the need for eco-conscious manufacturing practices, making aluminum an appealing choice due to its recyclability and reduced carbon footprint. The intersection of innovation and sustainability is set to redefine the landscape of aluminum kitchen profiles, offering exciting possibilities for both manufacturers and consumers alike.

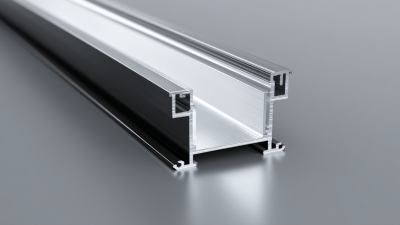

The advancements in aluminum processing technologies are steering the evolution of kitchen profiles towards greater efficiency and sustainability. Recent industry reports indicate that the global aluminum market is projected to grow by approximately 5.2% annually, fueled by innovative manufacturing techniques and the rising demand for energy-efficient solutions in residential and commercial spaces. The adoption of cutting-edge extrusion technologies is enabling manufacturers to create lightweight yet robust profiles, which not only enhance the aesthetic appeal of kitchens but also reduce energy consumption in production.

Furthermore, the opening of new facilities dedicated to green aluminum production demonstrates a commitment to sustainable practices within the industry. For instance, the launch of a new factory in India focused on producing environmentally friendly aluminum profiles reflects a paradigm shift towards sustainable sourcing and manufacturing processes. This aligns with projections that suggest a 30% increase in the demand for eco-friendly materials in the next five years, driven by consumer preferences for sustainable products. These innovations position aluminum kitchen profiles at the forefront of kitchen design, enhancing functionality while supporting eco-conscious initiatives.

| Technology Type | Description | Sustainability Impact | Market Adoption Rate (%) | Future Trends |

|---|---|---|---|---|

| Advanced Coating Technologies | Improves durability and aesthetics | Reduces environmental impact through lower maintenance | 75% | Increase in eco-friendly options |

| Aluminum Extrusion Process | Efficient shaping of aluminum profiles | Minimizes waste and enhances recyclability | 80% | Focus on energy-efficient machinery |

| Smart Manufacturing | Integrates IoT and AI in production | Reduces production energy consumption | 65% | Increasing automation and industry 4.0 |

| Recyclable Aluminum Alloys | Alloys specifically designed for recycling | Promotes circular economy | 70% | Broader acceptance in residential applications |

The role of sustainable practices in aluminum kitchen profile production is increasingly vital as the industry shifts towards greener solutions. Recent reports indicate that the global aluminum market is expected to witness substantial growth, driven by the rising demand for lightweight and durable materials in various applications, including kitchen profiles. A notable aspect of this growth is the emphasis on recycling and sustainability. For instance, aluminum can be recycled indefinitely without loss of quality, making it a perfect candidate for eco-friendly production methods.

Moreover, innovative technologies are being incorporated into aluminum production processes to enhance sustainability. Studies show that implementing advanced machinery can reduce energy consumption by up to 30% compared to traditional manufacturing methods. This advancement not only decreases the carbon footprint of aluminum kitchen profiles but also aligns with broader environmental goals.

As companies prioritize sustainable practices, the integration of recycled aluminum in new product lines further emphasizes the industry's commitment to eco-friendliness. With a strategic focus on these practices, the future of aluminum kitchen profiles looks promising, paving the way for a more sustainable and innovative kitchen environment.

As consumer awareness of environmental issues grows, the demand for eco-friendly aluminum solutions is experiencing a notable shift. This trend is not just limited to kitchen profiles but spans various markets, including packaging. For instance, the global market for customized dog tags is projected to reach $130.4 billion in 2024, driven in part by consumers preferring sustainable options. Similarly, the bottled water processing market is witnessing an increasing valuation due to advanced filtration and purification technologies, reflecting a broader consumer preference for sustainability in every sector.

The alcohol packaging market, expected to be valued at $69.2 billion in 2024, is another area where sustainability plays a critical role in driving growth. With consumers increasingly favoring sustainable packaging solutions, the compound annual growth rate (CAGR) for this sector is projected to surpass 4.7% from 2025 to 2034. Furthermore, the demand for sustainable materials in flexographic printing is set to rise, with an anticipated CAGR exceeding 14% from 2023 to 2032, highlighting a significant trend towards eco-conscious practices across various industries.

The kitchen design landscape is witnessing a transformative shift, particularly with the integration of aluminum profiles that marry aesthetics and functionality. Recent statistics indicate that the global aluminum market was valued at approximately $159 billion in 2022 and is projected to reach $189 billion by 2027, growth significantly driven by the demand for lightweight, durable, and sustainable materials in residential construction. As designers and homeowners increasingly prioritize eco-friendly options, aluminum's recyclability and energy efficiency make it a preferred choice in modern kitchens.

Innovative designs in aluminum kitchen profiles reflect this trend, showcasing sleek lines and minimalist flair that complement contemporary aesthetics while providing practical functionality. The use of aluminum not only allows for creative freedom in design but also enhances the durability of kitchen fixtures. In 2021, a survey revealed that 65% of homeowners consider sustainability as a crucial factor when renovating their kitchens. This indicates a growing awareness and demand for materials like aluminum that offer both performance and a smaller environmental footprint. By incorporating advanced technology, manufacturers are developing smarter aluminum profiles that ensure optimal space utilization, resilience against wear and tear, and ease of maintenance, setting a new standard in kitchen design.

The aluminum kitchen profile market is experiencing a notable transformation, driven by innovative technologies and growing sustainability concerns. The global market size for aluminum bottles is projected to reach $10.12 billion in 2024, with a remarkable growth trajectory that anticipates an increase to $16.56 billion by 2032. This reflects a robust compound annual growth rate (CAGR) as industries shift towards more sustainable packaging solutions.

One of the key factors influencing this growth is the integration of advanced manufacturing technologies that enhance the durability and aesthetic appeal of aluminum kitchen profiles. As the demand for eco-friendly products rises, manufacturers are focusing on improving the recyclability of aluminum, which already boasts a high recycling rate. The environmental impact is significant, with research indicating that recycling aluminum requires 95% less energy compared to producing new aluminum. This not only reduces carbon emissions but also positions aluminum as a viable option in environmentally conscious kitchen designs, catering to a market that increasingly values sustainability.

One of the key factors influencing this growth is the integration of advanced manufacturing technologies that enhance the durability and aesthetic appeal of aluminum kitchen profiles. As the demand for eco-friendly products rises, manufacturers are focusing on improving the recyclability of aluminum, which already boasts a high recycling rate. The environmental impact is significant, with research indicating that recycling aluminum requires 95% less energy compared to producing new aluminum. This not only reduces carbon emissions but also positions aluminum as a viable option in environmentally conscious kitchen designs, catering to a market that increasingly values sustainability.

As we look to the future, the synergy between innovative technology and sustainable practices will likely define the evolution of aluminum kitchen profiles, ensuring alignment with both consumer preferences and environmental responsibilities.