In the ever-evolving construction industry, sourcing high-quality materials is paramount to the success of any project. Among these materials, Building Aluminium Profiles have emerged as a versatile and sustainable choice, extensively utilized in various applications ranging from residential to commercial structures. According to a recent market report by Research and Markets, the global demand for aluminium profiles is expected to grow at a CAGR of 6.3% from 2022 to 2027, underscoring the increasing significance of this material in modern construction. Not only do these profiles offer superior strength-to-weight ratios, but advancements in manufacturing techniques have also enhanced their durability and aesthetic appeal. As architects and builders seek to optimize their projects, understanding how to effectively source Building Aluminium Profiles is crucial for achieving both economic and functional success.

The significance of high-quality aluminium profiles in building projects cannot be overstated. These profiles serve as essential structural components, providing strength, durability, and design flexibility to a myriad of applications. By using premium materials, builders can ensure that their projects withstand environmental challenges, such as corrosion and extreme weather conditions, thereby enhancing longevity and safety.

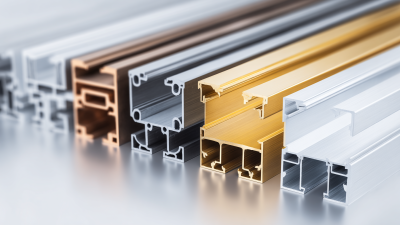

Moreover, high-quality aluminium profiles contribute to the overall aesthetic appeal of a building. The versatility of aluminium allows architects to craft innovative designs while maintaining structural integrity. This combination of functionality and aesthetics makes aluminium an increasingly popular choice in modern construction. Investing in high-quality profiles not only leads to superior performance but also reflects a commitment to excellence, ultimately resulting in projects that meet both the client’s expectations and industry standards.

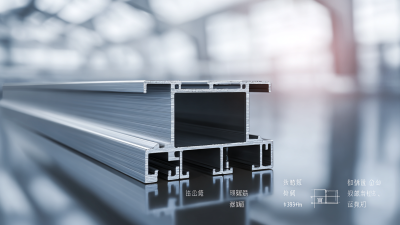

When sourcing high-quality building aluminium profiles for your projects, it's essential to focus on key specifications that ensure durability and performance. One crucial aspect to consider is the alloy composition of the aluminium. Look for profiles made from 6061 or 6063 alloys, as these offer excellent strength-to-weight ratios and corrosion resistance. These alloys are ideal for architectural applications, providing the structural integrity necessary for long-lasting performance.

Another important factor is the profile's surface treatment. Anodization not only enhances the aesthetic appeal but also improves the corrosion resistance of the aluminium, making it more suitable for outdoor use. In addition, check for specifications related to thickness and dimensional tolerances, as these will impact the profile's fit and durability in your construction. Ensuring that your supplier adheres to recognized industry standards can further guarantee the quality needed for your projects.

Tips: Always request product samples to evaluate the texture and finish, ensuring they meet your project’s visual and functional requirements. Additionally, consult with manufacturers about the specific application for which you need the profiles, as they can recommend the best products based on your needs. Taking these steps will help you source the best aluminium profiles for your construction projects.

When sourcing high-quality building aluminium profiles for construction projects, it is essential to engage with the top manufacturers and suppliers in the industry. The global aluminium sector is experiencing significant advancements, particularly in the extrusion market, where leaders are adopting innovative strategies to strengthen their market presence. Noteworthy developments include the expansion of manufacturing facilities, such as the recent announcement of a $4 billion plant set to open in the Port of Inola, which is projected to create over a thousand jobs. This represents a critical opportunity for builders to partner with leading suppliers and ensure a reliable source of quality materials.

In the current landscape, the aluminium profiles and accessories market is expected to grow dramatically, reaching approximately USD 123.44 billion by 2034. As industries globally adapt to new regulations and tariffs, like the recent increase in US tariffs on steel and aluminium imports, manufacturers are pivoting towards enhanced production capacities and innovative product offerings. By aligning with top suppliers that prioritize quality and sustainable practices, project managers can secure superior aluminium profiles that meet both aesthetic and structural requirements for modern construction projects.

Sourcing high-quality aluminium profiles for eco-friendly projects involves not just understanding the material but also embracing sustainable practices. The global green aluminium market is witnessing significant growth, driven by increasing demand for sustainable construction methods. As eco-conscious designs become mainstream, sourcing materials that align with environmental sustainability is crucial for any project.

Tip: When selecting aluminium profiles, prioritize suppliers who implement recycling processes and use renewable energy sources. Look for certifications that indicate compliance with environmental standards, ensuring that the material contributes positively to your project's green credentials.

Incorporating sustainable sourcing practices can also reduce costs in the long run. Green aluminium can lead to less energy consumption during production, making it a more efficient choice. By making informed decisions about suppliers and materials, project managers can align their goals with broader environmental objectives.

Tip: Establish long-term relationships with suppliers committed to sustainability; this can often lead to better pricing and priority access to the latest innovative products. Regularly assess and update your sourcing strategies to stay aligned with the evolving standards of the green building industry.

When it comes to sourcing high-quality building aluminium profiles, adopting cost-effective strategies is essential for both project budgeting and material integrity. One of the most effective ways to ensure you are getting quality profiles at a reasonable price is by conducting thorough supplier research. Look for manufacturers with a strong reputation within the industry and verify their certifications. Engaging directly with suppliers can also facilitate better negotiations, allowing you to secure discounts for bulk purchases or long-term contracts.

Another strategy worth considering is leveraging technology to streamline your procurement process. Online platforms and digital marketplaces can provide a wealth of options, enabling you to compare prices and specifications swiftly. Additionally, attending industry trade shows and exhibitions not only helps you connect with potential suppliers but also gives you the opportunity to evaluate product quality firsthand. By being proactive and utilizing these strategies, you can optimize your sourcing process and ensure that you are investing in aluminium profiles that meet your project's standards without overspending.