In the quest for energy efficiency and superior thermal performance, selecting the right materials is crucial, and one of the standout choices in modern construction is the Heat Insulation Aluminum Profile. These innovative profiles not only provide structural integrity but also enhance energy conservation by minimizing thermal bridges, making them ideal for a variety of applications. As more industries recognize the importance of sustainable practices, understanding the factors that influence the selection of heat insulation aluminum profiles becomes increasingly vital. This ultimate guide aims to equip you with comprehensive insights into the various types, features, and benefits of these profiles, ensuring that your projects are not only efficient but also environmentally friendly. Whether you are an architect, contractor, or DIY enthusiast, this guide will help you make informed decisions that align with your project needs and sustainability goals.

When selecting heat insulation aluminum profiles, it's essential to understand the various types available in the market to maximize energy efficiency in your projects. Key categories include standard thermal break profiles, enhanced thermal break profiles, and hybrid profiles. According to a report by the Aluminum Association, the adoption of advanced thermal insulation solutions has been shown to improve energy efficiency by up to 30%, making them a valuable investment.

Tips: When evaluating insulation efficiency, look for profiles that utilize materials with low thermal conductivity, such as polyurethane foam. This feature can significantly reduce heat transfer, optimizing the overall insulation performance.

Additionally, consider custom profiles that cater to specific project requirements. A study from the Global Aluminum Market indicates that architects are increasingly opting for bespoke designs, as they not only meet functional demands but also enhance aesthetic appeal. Choosing the right profile can lead to substantial long-term savings on heating and cooling costs, reinforcing its importance in the design process.

Tips: Always check the insulation values (e.g., U-values) for each profile, as these numbers reveal the efficiency of the aluminum profile in preventing heat loss or gain. A lower U-value indicates better insulation performance.

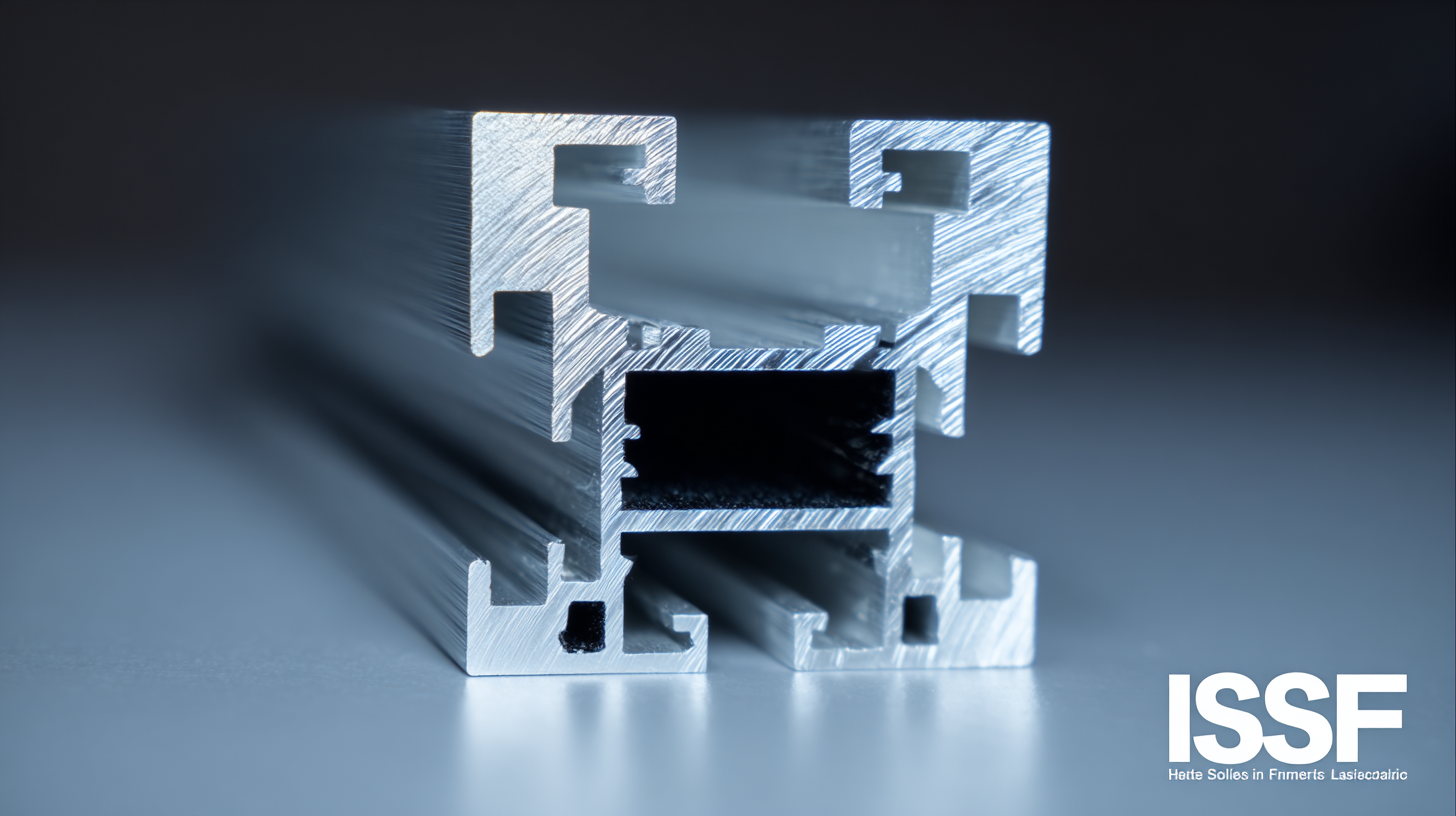

When selecting heat insulation aluminum profiles for construction projects, several common issues can significantly impact performance and efficiency. One major problem is thermal bridging, where heat flows through the materials, undermining their insulating effectiveness. According to a report by the Aluminum Association, approximately 30% of energy loss in buildings can be attributed to thermal bridging. This issue is particularly critical in regions with extreme temperature variations, making it vital for architects and builders to choose profiles designed with superior thermal break technologies.

Another prevalent issue is moisture infiltration, which can lead to mold growth and structural damage. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlighted that improperly sealed aluminum profiles can allow up to 20% more moisture into structures compared to properly insulated options. Consequently, it's essential to opt for profiles with advanced sealing capabilities and integrated drainage systems to mitigate these risks. Addressing these challenges not only enhances durability but also improves energy efficiency, vital for sustainability in modern construction.

| Profile Type | Thermal Conductivity (W/m·K) | Common Applications | Potential Issues |

|---|---|---|---|

| Standard Insulation Profile | 1.5 | Residential Windows | Condensation Risk |

| Low-E Insulated Profile | 0.5 | Commercial Buildings | Higher Cost |

| Thermal Break Profile | 0.7 | Industrial Applications | Complex Installation |

| Extruded Composite Profile | 0.6 | High-End Design | Durability Concerns |

When selecting heat insulation aluminum profiles, it’s vital to prioritize quality to ensure optimal performance in insulation. Quality profiles are designed with energy efficiency in mind, often featuring multi-chamber designs that create air pockets for better thermal insulation. According to industry reports, high-performance aluminum profiles can reduce heat loss by up to 30% compared to standard alternatives. This reduction is critical, especially in projects like garage renovations where maintaining a comfortable temperature is paramount during colder months.

Materials play a significant role in the effectiveness of heat insulation profiles. Selecting profiles that are specifically engineered to resist conduction and convection can result in substantial long-term savings on heating bills. Recent tests indicated that well-insulated spaces could save homeowners an average of 15-25% on their energy expenditures. Additionally, it’s essential to ensure that the profiles comply with safety standards, especially after incidents like the Grenfell Tower tragedy, where improper materials were used. Opting for fire-resistant and durable materials not only enhances safety but also contributes to the longevity of your projects.

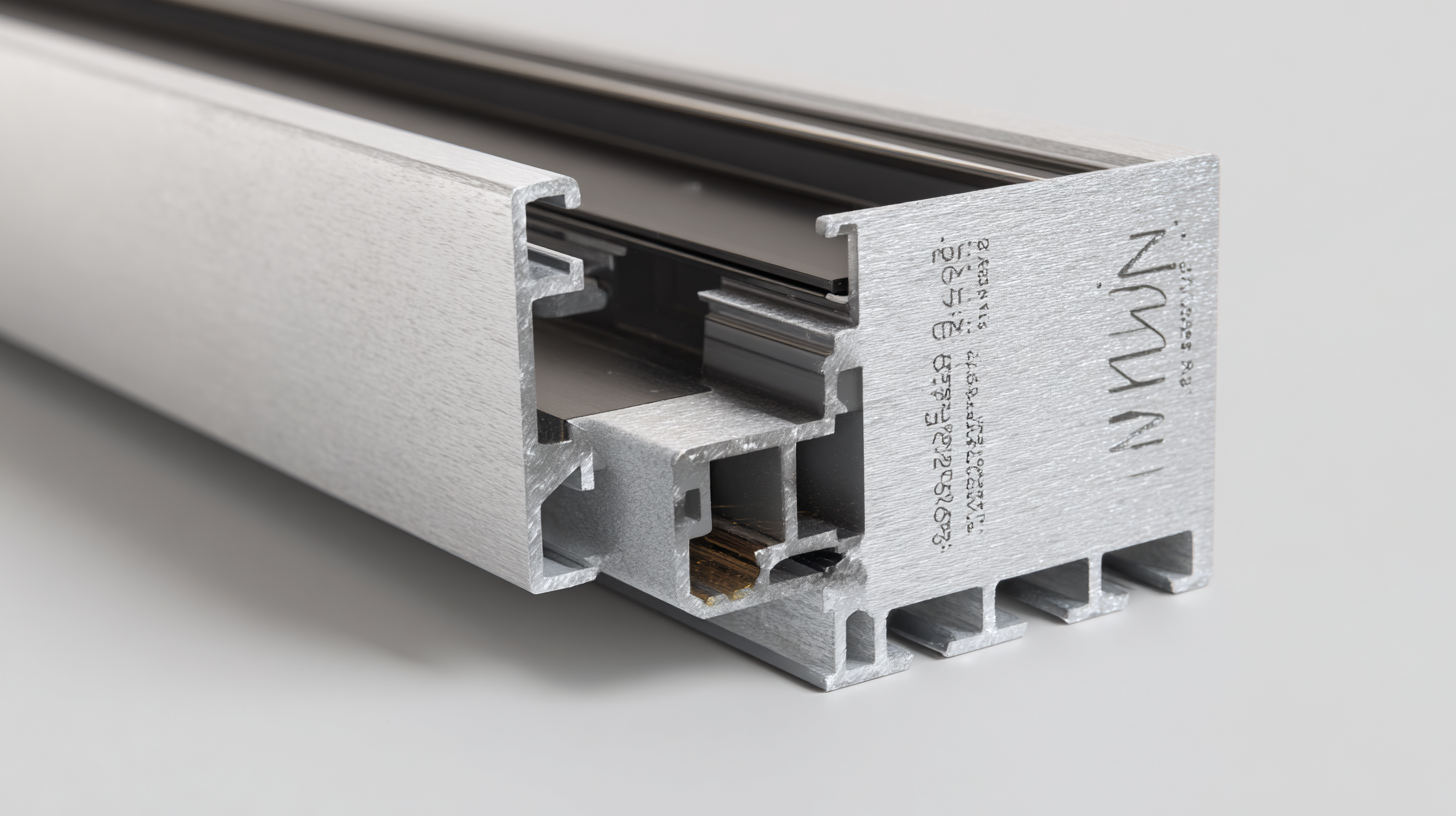

When installing heat insulation aluminum profiles, it is crucial to adhere to best practices to ensure optimal performance and longevity. According to a report by the Aluminum Association, properly installed insulation can enhance energy efficiency by up to 30%. This is significant in reducing heating and cooling costs for residential and commercial buildings. To achieve the best results, ensure that the profiles are free from any contaminants such as dust and grease which could disrupt the sealing process.

**Tips:** Always use a high-quality sealant specifically designed for aluminum profiles. This will not only improve insulation performance but also extend the lifespan of the installation. Additionally, it’s essential to allow for thermal expansion by incorporating expansion joints in your installation plan. Experts recommend planning joints every 10 feet to accommodate material shifts due to temperature changes.

Furthermore, ensure all joints are properly aligned and secure. Misalignment can lead to heat loss and ultimately result in increased energy consumption. The Institute of Thermal Insulation suggests that maintaining precise alignment and tight seals around gaps can improve insulation effectiveness by as much as 20%. Implementing these best practices will significantly enhance the overall efficiency of your project.

When choosing heat insulation aluminum profiles for your projects, it's crucial to balance cost against performance. Aluminum profiles are an essential component in various applications, providing not only structural integrity but also thermal efficiency. The initial purchase price can be tempting, but investing in higher-quality profiles can significantly reduce long-term energy costs. Therefore, understanding the thermal conductivity ratings and insulation properties of the profiles is vital in making an informed decision.

Furthermore, the intended application dictates the performance requirements. For instance, profiles used in industrial settings may require enhanced insulation properties to meet strict energy efficiency regulations. In contrast, residential applications might prioritize aesthetics alongside insulation performance. Comparing different products in terms of energy savings, durability, and potential maintenance costs ensures that you select a profile that not only fits your budget but also meets or exceeds performance expectations. Ultimately, making an informed choice leads to better overall value and sustainability in your projects.