The manufacturing and construction industries are undergoing a transformative phase, driven by innovation and the need for sustainable materials. A notable advancement lies in the utilization of Aluminum Handle Extrusions, which offer unparalleled strength, lightweight properties, and corrosion resistance, making them ideal for a variety of applications. According to a recent market report by Allied Market Research, the global aluminum extrusion market is projected to reach $77.8 billion by 2027, growing at a CAGR of 5.5% from 2020 to 2027. This rise is fueled by the escalating demand in construction and automotive sectors, where Aluminum Handle Extrusions play a critical role in enhancing product performance and longevity. As the world increasingly turns to reliable Chinese manufacturing, the consistent quality of these extrusions stands out, affirming their importance in creating durable and efficient solutions for modern engineering challenges.

The manufacturing and construction industries are witnessing a transformative shift towards efficiency and sustainability, with aluminum handle extrusions at the forefront. These extrusions are not only lightweight and durable but also demonstrate exceptional versatility, making them ideal for various applications. Emerging trends highlight the focus on reducing waste and optimizing resource use. By utilizing advanced extrusion techniques and innovative designs, manufacturers can minimize energy consumption and enhance product lifespan, contributing to a more sustainable future.

Moreover, the trend of incorporating recycled materials into aluminum handle extrusions is gaining momentum. This practice not only decreases the reliance on virgin materials but also lowers the carbon footprint associated with production processes. Manufacturers are increasingly adopting eco-friendly practices by sourcing aluminum scrap, further enhancing recycling efforts within the industry. As companies strive to meet sustainability goals, the importance of aluminum handle extrusions as an efficient, eco-conscious choice is becoming increasingly clear, paving the way for greener manufacturing practices.

In the construction industry, cost-effectiveness is a critical factor influencing material selection, and aluminum handle extrusions are proving to be more advantageous compared to traditional materials like steel and plastic. One of the key benefits of aluminum extrusions is their lightweight nature, which not only reduces transportation costs but also eases handling and installation on-site. Additionally, aluminum's resistance to corrosion and durability ensures that structures maintain their integrity over time, minimizing the need for frequent replacements or repairs.

Furthermore, the versatility of aluminum handle extrusions allows for innovative designs and applications in various construction projects. As manufacturers increasingly prioritize sustainable materials, aluminum stands out due to its recyclability and lower environmental impact during production compared to other metals. The ongoing advancements in aluminum processing technology further enhance its appeal, making it a smart, cost-effective choice for builders seeking to balance quality with budget constraints while contributing to a more sustainable construction future.

The performance metrics of aluminum handle extrusions are crucial in evaluating their strength and durability, particularly in manufacturing and construction applications. These metrics involve rigorous testing to assess the mechanical properties, such as tensile strength and impact resistance. Recent advancements in construction technologies, especially in concrete 3D printing, emphasize the importance of optimizing material formulations that enhance structural integrity. By integrating high-performance aluminum extrusions in these innovative systems, manufacturers can achieve not only lightweight designs but also increased load-bearing capabilities.

The advent of advanced manufacturing techniques, including optimized printing processes, sheds light on the importance of rheological properties and microstructure analyses. These components are integral for ensuring that aluminum extrusions meet the rigorous demands of modern construction. As the industry progresses, staying informed about these metrics will enable manufacturers to continuously innovate and refine their products for superior performance.

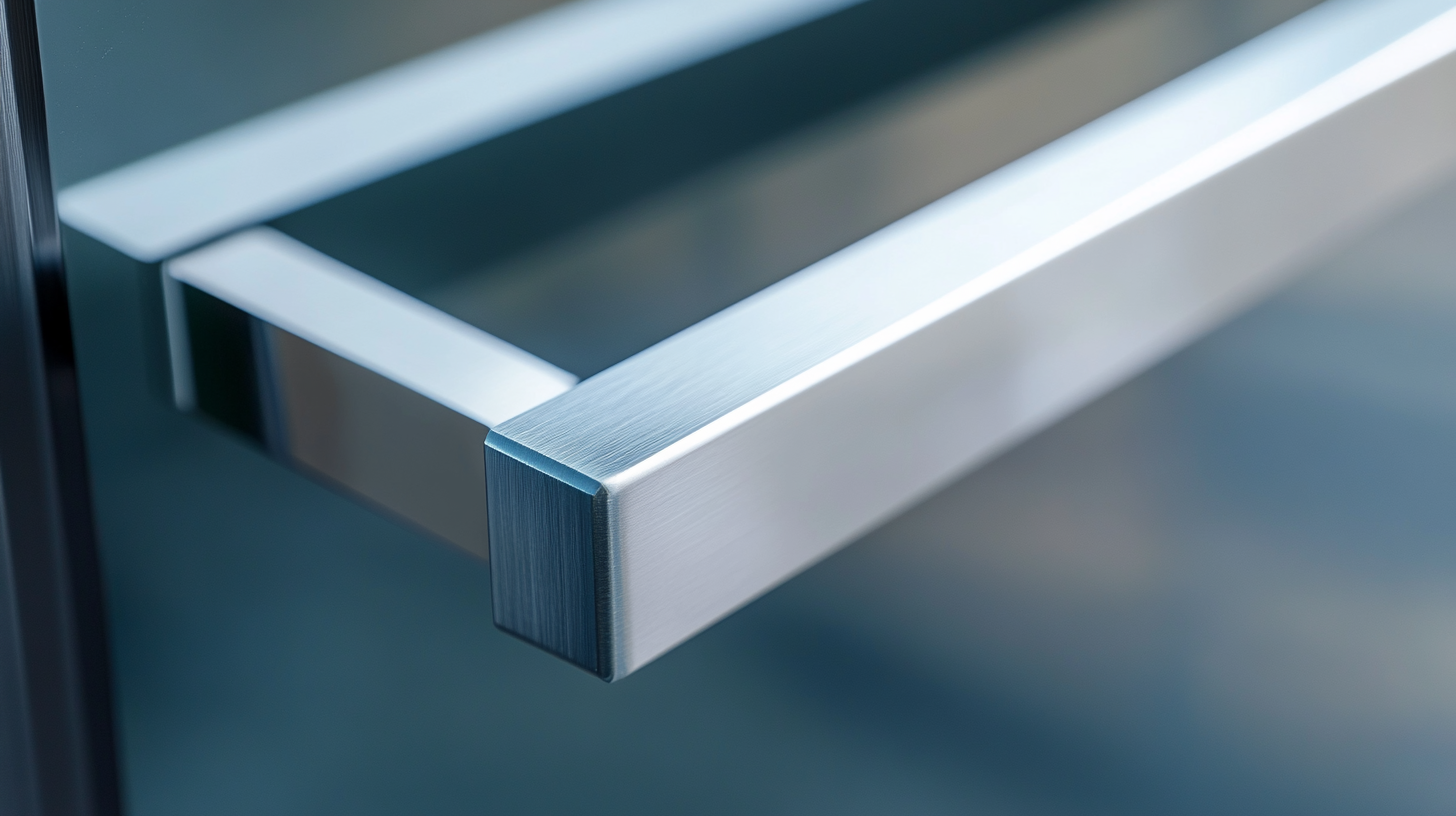

Aluminum handle extrusions are transforming the manufacturing and construction industries with their versatility and innovative applications. One notable trend is their use in ergonomic tools and equipment, where lightweight yet robust aluminum handles enhance user comfort and efficiency. These extrusions can be easily shaped and customized to fit different tool designs, allowing manufacturers to create products that meet specific ergonomic standards. As a result, users benefit from reduced strain during extended use, making aluminum handles the preferred choice for power tools, gardening implements, and various handheld devices.

Beyond tools, aluminum handle extrusions are finding unique applications in construction, particularly in modular building systems. The lightweight nature of aluminum allows for easier transportation and assembly of components, which speeds up the construction process. For instance, these extrusions are being utilized in panel systems, window frames, and doors, where strength and durability are paramount. By integrating aluminum handles into these systems, builders not only improve functional performance but also enhance aesthetic appeal. This innovation showcases the ability of aluminum extrusions to bridge the gap between functionality and design in modern construction projects.

The advancements in aluminum handle extrusion technologies are poised to reshape the manufacturing and construction industries significantly. As these applications evolve, innovative uses are surfacing, particularly in automation and product design. The lightweight yet durable nature of aluminum not only enhances efficiency but also reduces costs in production processes. Companies are increasingly adopting sophisticated aluminum extrusion techniques that allow for intricate designs, improving both functionality and aesthetic appeal.

Looking to the future, projections for aluminum handle extrusion technologies suggest a trend toward integration with 3D printing techniques. As the 3D printing metals market expands, aluminum is expected to play a pivotal role due to its favorable properties.

The synergy between traditional manufacturing methods and emerging technologies is likely to lead to higher customization levels, rapid prototyping, and ultimately more sustainable practices. As companies focus on reducing waste and increasing production efficiency, aluminum handle extrusions will remain at the forefront of innovations in construction and manufacturing sectors.