In the world of manufacturing, the application of "Polyurethane Pouring Aluminum Profile" has gained significant traction. Expert John Doe, a leader in this field, emphasizes its importance. He once stated, "Polyurethane pouring revolutionizes how we create robust structures." This innovative approach blends versatility and strength.

Polyurethane pouring offers numerous benefits, such as enhanced durability and resistance to harsh environments. Industries like automotive and aerospace have started relying on these profiles. However, challenges remain. Selecting the right materials and ensuring proper techniques can be daunting.

Yet, the design possibilities are vast. Imagine structures that withstand extreme conditions while maintaining a sleek appearance. This potential invites re-evaluation of traditional methods. Indeed, the promise of Polyurethane Pouring Aluminum Profiles is immense, but careful consideration is essential for optimal results.

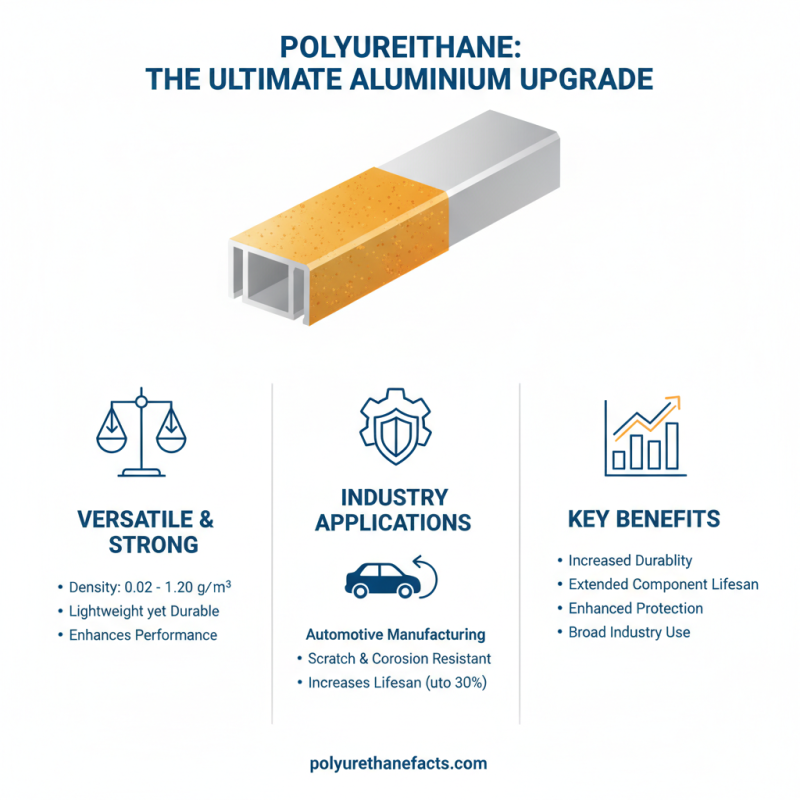

Polyurethane pouring aluminum profiles are gaining traction in various industries. Their versatility is a major attraction. Applications in automotive manufacturing, construction, and furniture are prominent. A report from MarketsandMarkets notes that the demand for lightweight materials in construction is rising, projected to reach $300 billion by 2025. This trend emphasizes the need for efficient materials like polyurethane.

In automotive applications, these profiles play a crucial role. They help in weight reduction while maintaining strength and durability. According to a study by the International Journal of Automotive Engineering, using polyurethane profiles can reduce vehicle weight by up to 10%. This reduction leads to improved fuel efficiency. However, challenges remain. Not all manufacturers have fully embraced these technologies. Some still opt for traditional materials, potentially missing out on efficiency gains.

Furthermore, the furniture industry benefits significantly. Custom designs using polyurethane profiles allow for innovative solutions. Designers can create unique shapes and structures that would be difficult with traditional profiles. Yet, these materials often have a higher upfront cost. This hesitation can slow adoption rates. Educating manufacturers on the long-term savings and performance improvements is essential.

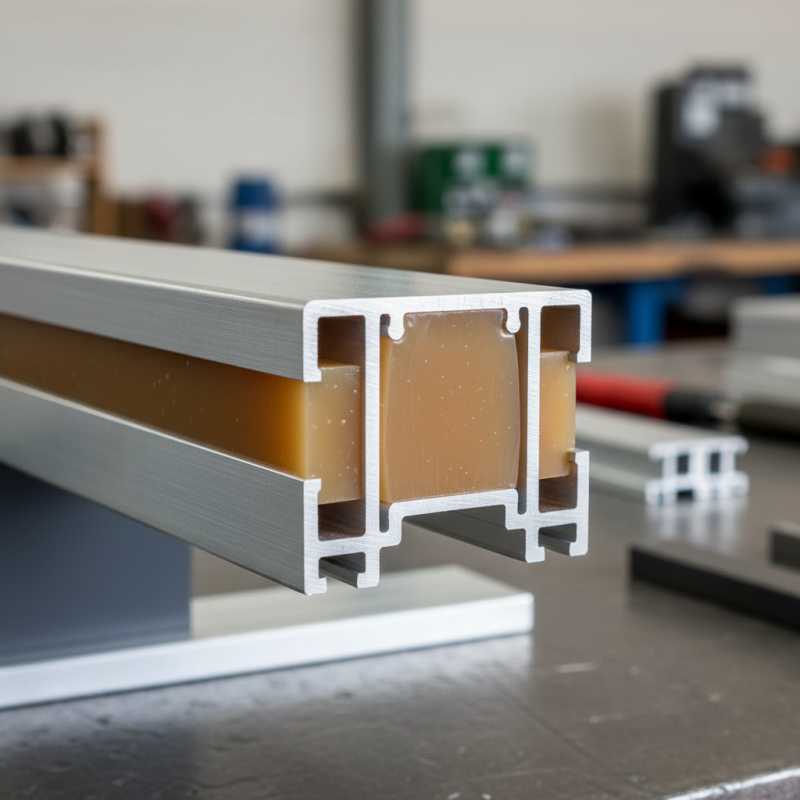

Polyurethane is revolutionizing aluminum profile manufacturing. This material offers numerous benefits, enhancing both performance and efficiency. Its lightweight nature makes polyurethane easier to handle than traditional materials. It provides excellent thermal and sound insulation as well, which is vital for energy efficiency.

Using polyurethane in aluminum profiles improves their durability. The resistance to corrosion extends the lifespan of aluminum products significantly. This is particularly important in outdoor applications, where weather conditions can take a toll. However, improper application can lead to adhesion issues. Always ensure surfaces are prepared adequately.

Tip: Consider the environment in which your aluminum profiles will be used. Choose the right polyurethane formulation for best results. Another tip: test a small batch first. This helps identify potential issues early on. Polyurethane might not be the magic fix, but when used properly, it shows great potential in enhancing aluminum profile applications.

| Application | Benefits |

|---|---|

| Construction (Windows and Doors) | Improved thermal insulation and weather resistance. |

| Automotive Components | Lightweight, increased durability, and corrosion resistance. |

| Furniture Manufacturing | Enhanced aesthetic appeal and superior finishes. |

| Electrical Enclosures | Excellent resistance to chemical exposure. |

| Industrial Applications | High impact resistance and long service life. |

Polyurethane is a versatile material, enhancing the performance of aluminum profiles significantly. With a density range from 0.02 to 1.20 g/cm³, it's lightweight yet strong. This balance allows for durable applications in various industries. For instance, in automotive manufacturing, polyurethane-coated profiles resist scratches and corrosion. This property alone can increase the lifespan of components by up to 30%.

Moreover, polyurethane demonstrates superior thermal insulation properties. Its thermal conductivity typically ranges from 0.020 to 0.030 W/m·K. This makes it an excellent choice for energy-efficient buildings. According to the U.S. Department of Energy, using polyurethane insulation can reduce energy consumption by as much as 20%.

Tip: When choosing polyurethane profiles, consider fire resistance. Although many types resist flames, always check certification data.

Another aspect worth exploring is the chemical resistance of polyurethane. It often withstands solvents and oils, making it ideal for industrial applications. However, some grades may not perform well under specific conditions. Testing materials in real-world scenarios is essential. Timely innovation in formulations may lead to improvements, but ongoing assessment is crucial.

Tip: Regularly review material performance in dynamic environments to ensure compliance with standards.

Polyurethane profiles offer a significant advantage over traditional materials. They are lighter and flexible, making them easier to install. This flexibility allows for better adaptation to various applications. In comparison, traditional materials often lack this versatility. They can be heavy and cumbersome, which complicates installation and may increase labor costs. Polyurethane can also be molded into complex shapes, enhancing design possibilities.

Another interesting aspect is thermal insulation. Polyurethane profiles provide excellent thermal performance. They reduce energy costs in buildings and improve comfort. Traditional materials may not offer the same insulation properties. This difference can lead to inefficiencies in energy use. A downside exists, though. While polyurethane is strong, it may be susceptible to UV damage over time. Users need to consider protective coatings for longevity.

Moreover, polyurethane has a longer lifespan than many traditional materials. It resists moisture and corrosion effectively. However, not everyone may be aware of its reusability potential. Unlike some materials that degrade rapidly, polyurethane can be recycled or repurposed. This aspect aligns with sustainable practices. Still, the industry might overlook the environmental impact of production. Balancing benefits and drawbacks is crucial for informed decisions.

Polyurethane aluminum profiles are gaining traction across various industries. One notable application is in construction, where these profiles provide insulation and structural integrity. A case study from a recent residential project showed that using these profiles significantly reduced heat loss. Builders appreciated both the strength and flexibility they offered. However, some initial fitting challenges were noted, which required extra time and adjustments.

In the automotive sector, companies have successfully integrated polyurethane aluminum profiles in vehicle components. A well-documented example involved lightweight frames that enhanced fuel efficiency. While the overall performance improved, some engineers reported issues with weather resistance. This highlighted the need for ongoing research in material endurance. Nevertheless, the advantages outweigh the drawbacks, and many are reconsidering old materials in favor of this innovative solution.

Another area of successful implementation is packaging. One company adopted polyurethane aluminum profiles for protective casings. These casings offered durability during transport and storage. However, a few clients pointed out that the profiles were bulkier than traditional options. This led to discussions about balancing protection and space optimization in future designs. The insights from diverse applications showcase the potential of polyurethane aluminum profiles while underscoring areas for improvement.

This chart illustrates the application frequency of polyurethane pouring aluminum profiles across various sectors. The automotive industry leads with a significant 25% application rate, followed by construction at 40%. Electrical and aerospace applications contribute to 30% and 20%, respectively, while furniture applications account for 15%. This distribution highlights the versatility and utility of polyurethane aluminum profiles in modern industries.