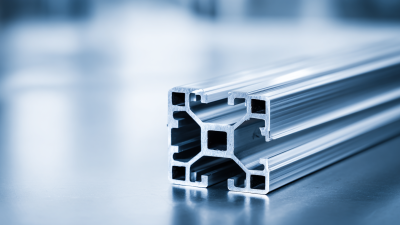

The **Polyurethane Pouring Aluminum Profile** is gaining attention for its unique advantages. This material combines the durability of aluminum with the flexibility of polyurethane. Industries are increasingly adopting this combination for various applications.

One major benefit is its lightweight nature. Projects can be completed more efficiently due to reduced material weight. Additionally, the polyurethane coating provides excellent resistance to environmental factors. This helps prolong the lifespan of the profiles, making them a cost-effective solution. However, some manufacturers may not maximize the potential of this material.

Despite its benefits, there are challenges. Not every project may benefit equally from a **Polyurethane Pouring Aluminum Profile**. It's crucial to assess specific needs and conditions. Some users might overlook this step, leading to suboptimal results. Overall, understanding the advantages and limitations is essential for effective implementation.

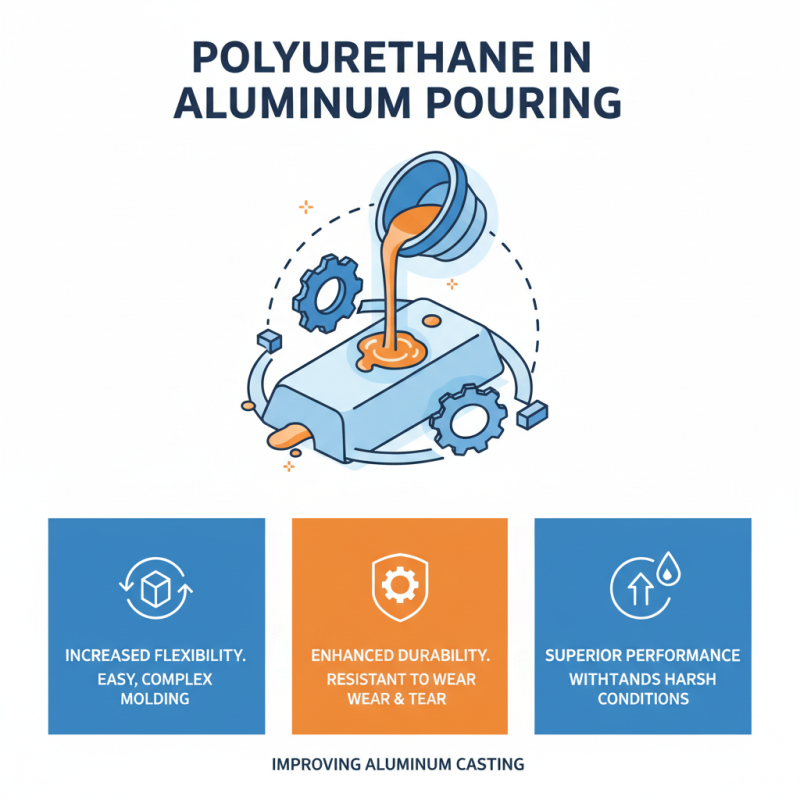

Polyurethane has become essential in aluminum profile pouring, bringing substantial benefits. One of the main advantages is its durability. Reports indicate that polyurethane pours can extend the lifespan of aluminum profiles by up to 30%. This increased longevity can reduce overall production costs and waste, making it a more sustainable option.

The flexibility of polyurethane is another significant benefit. It can accommodate various shapes and sizes, ensuring a better fit during the production process. Industry surveys suggest that manufacturers who utilize polyurethane have seen a 25% increase in production efficiency. This adaptability allows for more innovative designs, opening new possibilities for applications.

Polyurethane is increasingly used in aluminum pouring applications. Its unique characteristics enhance performance and durability. One key feature is its impressive flexibility. This allows for easy molding, creating complex shapes without losing strength. Additionally, polyurethane exhibits excellent resistance to wear and tear. It stands strong against harsh environmental conditions, ensuring longevity in various applications.

Another noteworthy aspect is its lightweight nature. This can lead to reduced transportation costs and easier handling. Despite its robustness, polyurethane can be crafted to meet specific needs, making it adaptable. However, it's crucial to monitor the curing process. Inconsistent curing can result in weaknesses. Mistakes during this phase can diminish its beneficial properties.

Lastly, polyurethane’s thermal stability is significant. It resists degradation when exposed to high temperatures. This is particularly useful in industrial settings. But, temperature fluctuations during application could pose challenges. Proper measures should be taken to ensure effective use. Overall, polyurethane provides substantial benefits for aluminum profiles in various industries.

Polyurethane profiles offer remarkable durability and performance advantages, especially in the construction industry. Research from the American Institute of Architects points out that structures using polyurethane show over over 30% less wear and tear compared to traditional materials. This difference translates to lower maintenance costs and longer lifespans for buildings and infrastructure.

Enhanced impact resistance is one notable benefit. Testing indicates that polyurethane can endure severe weather and physical stress better than other polymers. For instance, profiles made from polyurethane can withstand temperatures ranging from -40°F to 180°F without losing integrity. However, the challenge lies in ensuring proper installation to maximize these benefits. Misalignment during fitting can compromise performance.

The long-term performance of polyurethane profiles is also noteworthy. Studies reveal that these materials retain their properties even after years of exposure to UV light and moisture. Reports suggest that buildings utilizing polyurethane can expect enhanced energy efficiency due to better insulation properties. Despite these advantages, some engineers remain skeptical, focusing on potential issues such as initial cost and installation complexity.

When comparing polyurethane to other materials for aluminum profiles, several key advantages arise. Polyurethane offers superior insulation properties, making it an ideal choice for energy-efficient applications. According to industry data, polyurethane can provide approximately 50% better thermal efficiency than traditional materials like PVC or EPDM. This makes it particularly valuable in sectors demanding tight temperature control.

Additionally, polyurethane is known for its excellent durability and flexibility. Reports indicate that polyurethane can withstand extreme weather conditions, resisting abrasions and chemical exposure better than alternatives. Moreover, its lightweight nature simplifies handling and reduces transportation costs. However, while benefiting from these properties, we must also consider the environmental impact. The production of polyurethane can have significant carbon footprints, necessitating ongoing advancements in sustainable practices.

Cost is another critical factor. While polyurethane's performance is exceptional, the initial investment may be higher compared to materials like standard aluminum or steel. This reality can pose challenges for budget-conscious projects. Analyzing total lifecycle costs is essential to justify this decision. It is vital to balance performance with sustainability and cost to ensure optimal material selection.

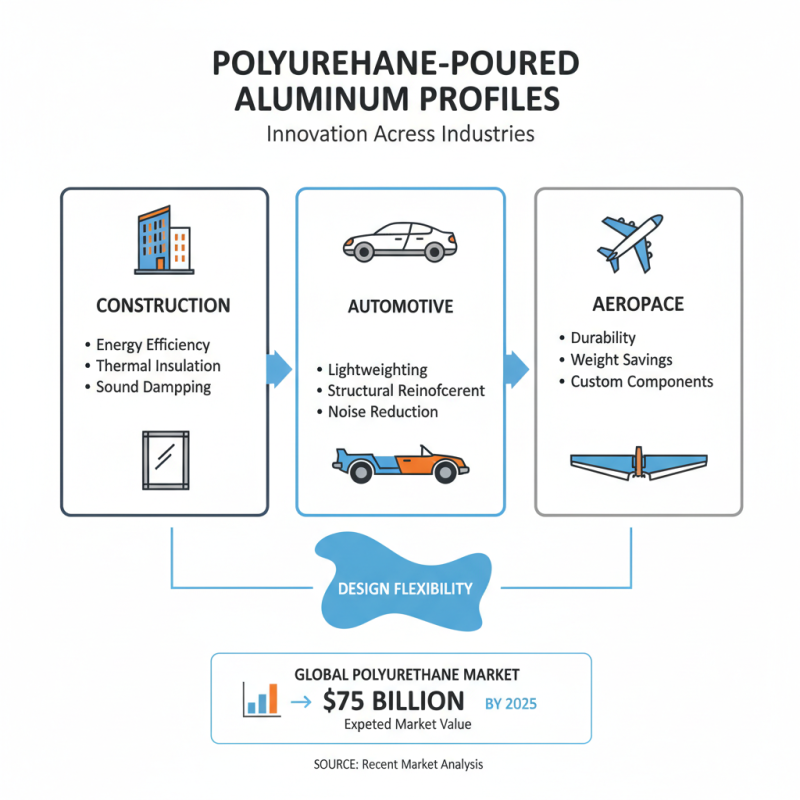

Polyurethane pouring aluminum profiles are gaining traction across various industries. They are particularly popular in construction, automotive, and aerospace sectors. The flexibility in design is a major advantage. According to a recent market analysis, the global polyurethane market is expected to reach $75 billion by 2025, driven by demand in these industries.

Construction projects often utilize these profiles for insulation and weatherproofing. They can be molded into complex shapes, making them ideal for unique architectural designs. The automotive industry benefits from their lightweight properties, enhancing fuel efficiency. A report from Industry Research states that lightweight materials are projected to account for 25% of total car weight by 2030.

Challenges remain, though. The production process can be intricate and requires precision. Any error in the pouring process may lead to defects. These defects can compromise the strength and durability of the profiles. Additionally, not all companies have adopted these materials. Understanding how to balance costs and benefits is crucial for wider adoption.