In today's global marketplace, the demand for high-performance building materials is continually on the rise, particularly in the realm of insulation and energy efficiency. Among the leading solutions in this field are Thermal Break Aluminum Profiles, which have gained significant attention for their exceptional thermal insulation properties and sleek aesthetic appeal.

As a quality-focused manufacturing powerhouse, China has positioned itself at the forefront of this industry, exporting top-tier thermal break aluminum profiles to countries worldwide. This blog will delve into the intricacies of China's manufacturing capabilities, exploring how adherence to stringent quality standards, innovative production techniques, and commitment to sustainability have propelled these factories to the global forefront.

Join us as we uncover the secrets behind the success of these manufacturers, who are not only meeting the rising demand but also setting trends in modern architectural design.

In the realm of global manufacturing, the significance of adhering to quality standards cannot be overstated, particularly in the production of thermal break aluminum profiles. As China emerges as a powerhouse in this industry, its commitment to quality benchmarks is pivotal for ensuring that products not only meet domestic requirements but also satisfy international markets. This focus on quality involves rigorous testing and compliance with various international standards, allowing manufacturers to bolster their reputation and reliability.

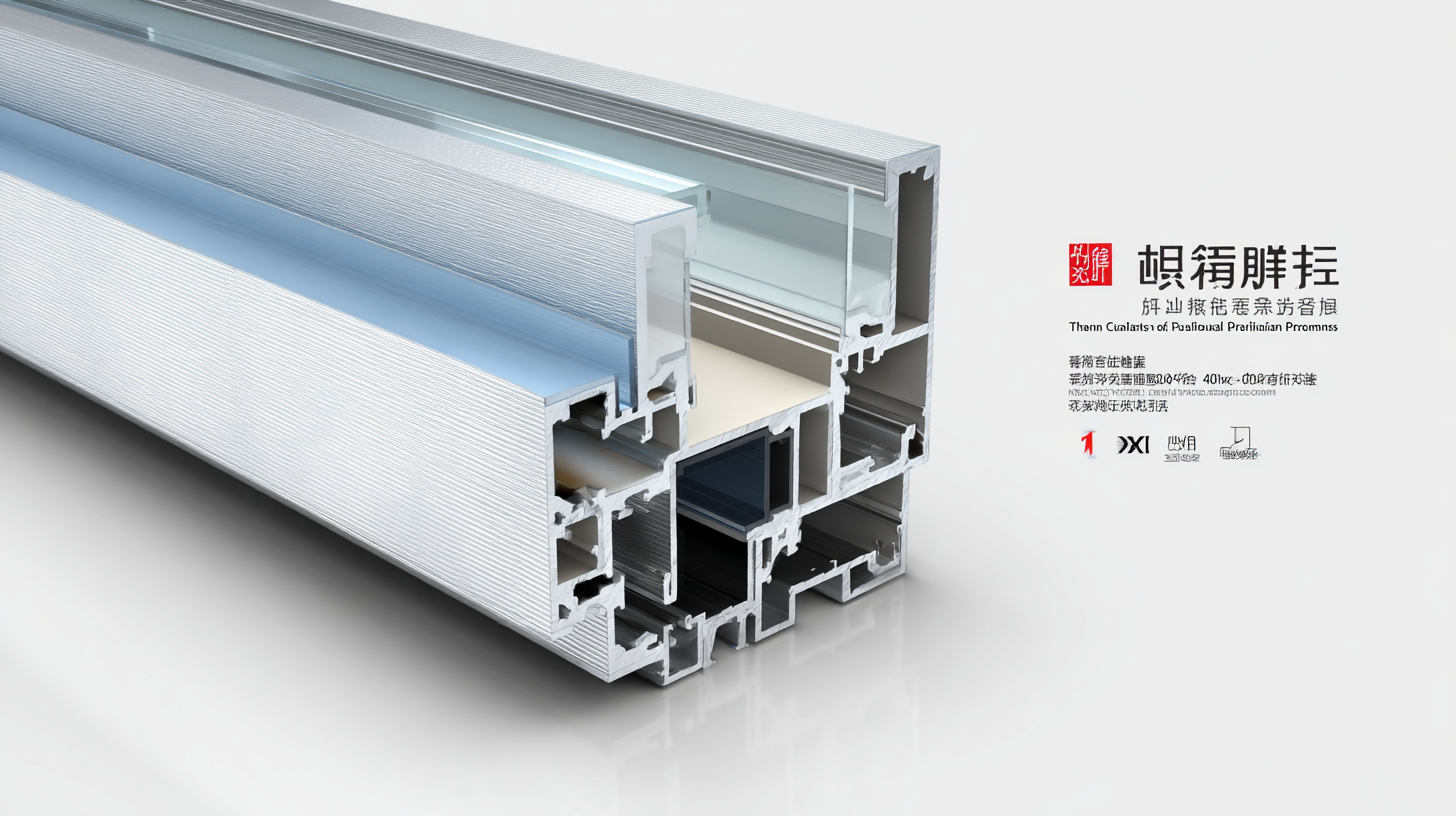

Moreover, quality standards play a crucial role in enhancing the technical performance of thermal break aluminum profiles. These profiles are essential for improving energy efficiency in buildings, and any lapse in quality could result in subpar insulation and increased energy costs for consumers. By prioritizing stringent quality control processes, Chinese manufacturers are not only contributing to sustainable practices but are also empowering their clients with products that promise durability and effectiveness. As global demand for such high-performing materials increases, the emphasis on quality in Chinese manufacturing remains a key asset in gaining a competitive edge on the world stage.

In recent years, China's manufacturing sector has seen remarkable technological advancements that have significantly enhanced production efficiency and quality, especially in the production of thermal break aluminum profiles. These innovations encompass state-of-the-art machinery, automation, and data-driven processes that streamline operations. By integrating smart technology into the manufacturing process, companies can monitor production in real-time, minimizing errors and optimizing resource utilization.

Tip: Embracing automation can drastically reduce production time and improve precision. Consider investing in robotic systems for tasks such as welding and assembly to keep up with the growing demand for high-quality aluminum profiles.

Moreover, advancements in materials technology have led to the development of stronger and more durable aluminum alloys. These improved materials not only increase the thermal efficiency of products but also extend their lifespan, offering greater value to customers on a global scale.

Tip: Regularly update your material suppliers and stay informed about the latest trends in aluminum alloys. This will ensure that your products remain competitive in the international market by meeting the highest standards of quality and performance.

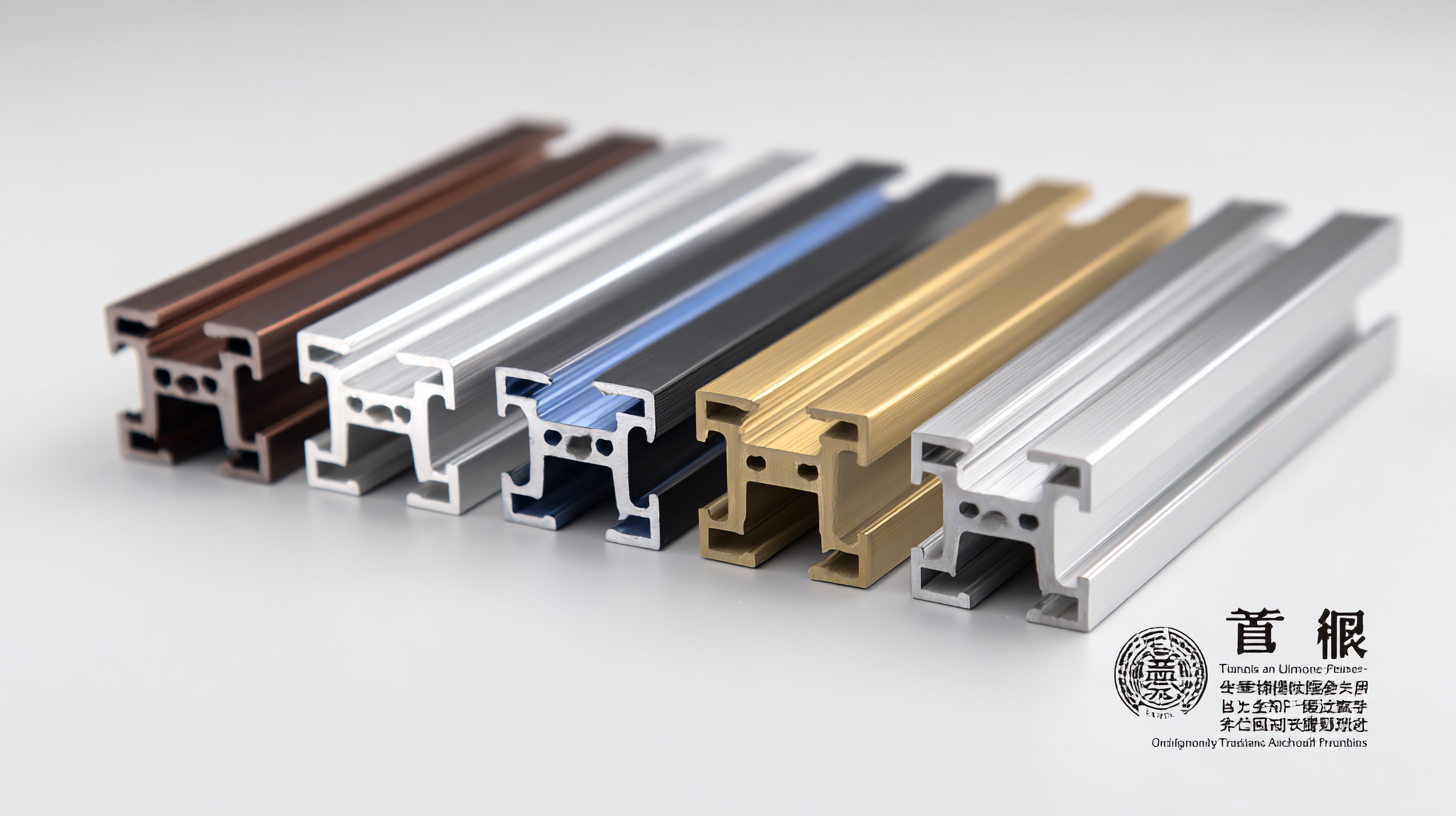

In recent years, the global market has witnessed a significant surge in demand for high-quality thermal break aluminum profiles. This shift is primarily driven by the construction industry's growing emphasis on energy efficiency and sustainable building practices. Thermal break aluminum profiles not only enhance the thermal performance of buildings but also provide durability and aesthetic appeal, making them an essential choice for architects and builders alike. As a result, manufacturers are prioritizing the development of innovative designs and techniques to meet this rising demand.

Chinese manufacturers, known for their robust production capabilities and technological advancements, are stepping up to fulfill the global need for premium thermal break aluminum profiles. By focusing on quality, manufacturers ensure that their products comply with international standards while also meeting the specifications and preferences of diverse markets. This quality-centric approach not only benefits the end-users in terms of performance and reliability but also positions Chinese manufacturing as a competitive force in the global marketplace for aluminum profiles. As market dynamics evolve, it is imperative for manufacturers to continue investing in their quality control measures and innovative solutions to maintain their leadership in this lucrative segment.

Sustainable practices in Chinese manufacturing have gained prominence, especially in the production of thermal break aluminum profiles for global export. As the world increasingly demands eco-friendly solutions, manufacturers in China are innovating their processes to reduce environmental impact. By implementing energy-efficient technologies and optimizing resource management, these companies are not only meeting international standards but also enhancing their competitive edge in the global market.

Sustainable practices in Chinese manufacturing have gained prominence, especially in the production of thermal break aluminum profiles for global export. As the world increasingly demands eco-friendly solutions, manufacturers in China are innovating their processes to reduce environmental impact. By implementing energy-efficient technologies and optimizing resource management, these companies are not only meeting international standards but also enhancing their competitive edge in the global market.

Furthermore, the adoption of recycled materials in the fabrication of aluminum profiles plays a significant role in sustainability. This practice not only conserves natural resources but also minimizes waste. Chinese manufacturers are increasingly focusing on transparency in their supply chains, ensuring that their sourcing of materials aligns with global sustainability goals. These efforts reflect a commitment to creating products that are not only high in quality but also supportive of a more sustainable future, appealing to eco-conscious consumers around the world.

In 2025, the competitive landscape for manufacturers globally is expected to shift dramatically, especially for those focusing on quality. Total Quality Management (TQM) will be pivotal in instilling a culture of excellence within manufacturing firms. By embracing TQM principles, businesses can enhance operational efficiency and significantly improve customer satisfaction through consistent product quality. This focused approach allows firms to foster loyalty and gain an edge in international markets, where quality is paramount.

**Tips:** Implementing TQM involves regular training sessions for employees to ensure they are equipped with the necessary skills to maintain high standards. Additionally, utilizing big data analytics can offer insights into production processes, helping to identify areas for improvement and streamline operations. Finally, cultivating a feedback loop with customers ensures that their needs are heard and addressed, further enhancing the perceived value of products.

As manufacturers adopt a service-oriented model in response to Industry 4.0, the integration of product development with service innovation becomes essential. Companies must remain adaptable, leveraging advanced technologies to meet evolving customer demands and stay ahead in the competitive manufacturing landscape. This approach not only improves quality but also sets a pathway for sustained growth in a rapidly changing market.