In recent years, the construction and industrial sectors have increasingly recognized the importance of energy-efficient materials, with studies revealing that buildings account for approximately 40% of global energy consumption. Among the various choices available, "Broken Bridge Aluminum Profiles" stand out for their superior thermal insulation and durability. According to a report by the Aluminum Association, the use of aluminum profiles can significantly enhance energy efficiency, reducing heating and cooling costs by up to 30%. These profiles not only contribute to sustainability but also ease installation and enhance aesthetic appeal, making them an ideal choice for modern architecture. As we delve into the specific advantages of Broken Bridge Aluminum Profiles, it becomes clear why they are increasingly favored for a wide range of projects, from residential structures to commercial developments, offering both performance and cost-effectiveness in today's competitive market.

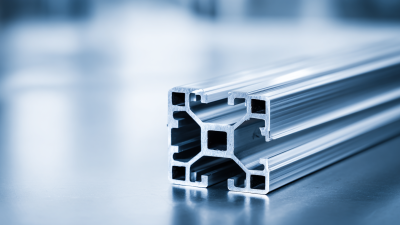

When it comes to thermal insulation efficiency in building projects, broken bridge aluminum profiles stand out as an optimal choice. These profiles are specifically designed to minimize heat transfer, making them ideal for energy-efficient construction. According to a report by the American Architectural Manufacturers Association (AAMA), aluminum windows with thermal breaks can achieve a reduction in whole-window U-values by up to 50% compared to traditional aluminum frames. This significant improvement translates into lower energy costs and a more comfortable indoor environment.

Moreover, the benefits of broken bridge aluminum profiles extend beyond just thermal efficiency. A study from the National Institute of Standards and Technology (NIST) highlights that buildings utilizing high-performance thermal barrier materials can experience energy savings of approximately 30% annually. By incorporating broken bridge technology, architects and builders can meet or exceed these standards while providing durability and aesthetic appeal. This makes broken bridge aluminum profiles not only a smart investment but also a responsible choice for environmentally conscious design.

When considering materials for construction projects, durability and maintenance are paramount. Broken Bridge Aluminum Profiles stand out due to their robust structure and resistance to environmental wear and tear. These profiles are specifically designed with thermal breaks, which significantly enhance their insulation properties. This feature not only contributes to energy efficiency but also reduces the likelihood of condensation, minimizing potential damage over time.

Furthermore, Broken Bridge Aluminum Profiles require minimal maintenance compared to traditional materials. Unlike wood or steel, which can suffer from rot, rust, or corrosion, aluminum profiles are naturally resistant to these issues. Their surface is treated to withstand harsh weather conditions, requiring only occasional cleaning to maintain their aesthetic appeal. This low-maintenance requirement not only saves time and costs over the lifespan of a building but also makes Broken Bridge Aluminum Profiles a smart, long-term investment for any construction project.

When embarking on your next construction project, the choice of materials can significantly impact both initial costs and long-term savings. Broken Bridge Aluminum Profiles stand out as a cost-effective solution, especially for those considering energy efficiency. These aluminum profiles can enhance insulation in buildings, leading to reduced energy consumption and, consequently, lower utility bills over time. In regions like Northwest China, where rural homes often lack proper energy-saving features, investing in high-quality materials like Broken Bridge Aluminum Profiles can greatly improve energy performance.

**Tip:** When selecting materials for your project, consider the thermal efficiency they provide. Choosing options that minimize heat transfer can lead to a more comfortable living environment and decreased energy costs.

Additionally, Broken Bridge Aluminum Profiles are not only durable but also require minimal maintenance, which translates into further savings in repair and replacement costs. Their longevity ensures that you will not have to reinvest in materials frequently, a common issue in self-built structures that often fall short in energy performance.

**Tip:** Look for products that offer a warranty or guarantee, as this can provide peace of mind and added value. Investing in durable materials can help you avoid unexpected expenses in the future.

| Factors | Description | Long-Term Savings |

|---|---|---|

| Durability | Resistant to corrosion and weathering, ensuring longevity. | Reduces costs of replacements and repairs. |

| Energy Efficiency | Improves insulation properties, lowering heating and cooling costs. | Saves up to 30% on energy bills. |

| Lightweight | Easier handling and installation, reducing labor costs. | Decreases time on site, saving on project duration. |

| Low Maintenance | Requires minimal upkeep compared to other materials. | Lowers maintenance costs over time. |

| Recyclability | Made from recyclable materials, promoting sustainability. | Potential savings from recycling programs. |

| Thermal Break | Prevents heat transfer, enhancing energy efficiency. | Reduces energy costs significantly. |

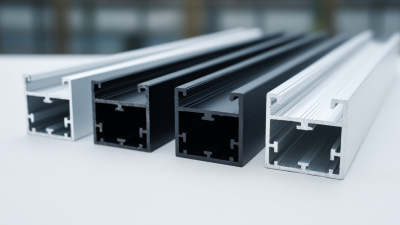

When embarking on your next architectural project, the design flexibility offered by

Broken Bridge aluminum profiles plays a crucial role in meeting aesthetic and functional requirements.

These profiles can be customized to fit diverse design specifications, allowing for innovative solutions in energy-efficient construction. According to the

Aluminum Association, using aluminum can result in energy savings of up to

30% over the lifespan of a structure, particularly when optimized with custom profiles that enhance insulation and thermal performance.

When embarking on your next architectural project, the design flexibility offered by

Broken Bridge aluminum profiles plays a crucial role in meeting aesthetic and functional requirements.

These profiles can be customized to fit diverse design specifications, allowing for innovative solutions in energy-efficient construction. According to the

Aluminum Association, using aluminum can result in energy savings of up to

30% over the lifespan of a structure, particularly when optimized with custom profiles that enhance insulation and thermal performance.

One of the standout features of Broken Bridge aluminum profiles is their ability to accommodate complex shapes and sizes without compromising structural integrity. This characteristic not only broadens the design possibilities but also supports sustainable architecture by utilizing lightweight materials that minimize resource consumption. By integrating these profiles, architects can leverage cutting-edge design technologies to create striking facades while reducing environmental impact.

Tips: When considering aluminum profiles for your project, always consult with suppliers about their customization capabilities. A detailed consultation process can reveal unique solutions tailored to your specific design challenges. Additionally, explore options that incorporate thermal breaks to boost energy efficiency, as studies show that a well-designed thermal break can significantly enhance a building's overall performance.

When considering materials for construction and design projects, sustainability is a vital factor that cannot be overlooked.

Broken Bridge Aluminum Profiles stand out as an eco-friendly choice due to their energy-efficient properties and recyclability.

The innovative design of these profiles minimizes energy loss, providing excellent thermal insulation and reducing the energy required for heating or cooling spaces.

This not only contributes to lower utility bills but also lessens the overall carbon footprint of a building.

Moreover, Broken Bridge Aluminum Profiles are made from recyclable materials, making them an environmentally responsible option.

When the profiles reach the end of their life cycle, they can be recycled and repurposed without losing their structural integrity.

This cycle of use and reuse not only conserves natural resources but also reduces waste in landfills.

By choosing these aluminum profiles, you are not only investing in

temporary building solutions but also contributing to a sustainable future, allowing projects to integrate

seamlessly with the global push for greener practices.