In the realm of architectural design and construction, the importance of Thermal Break Aluminum Extrusion has gained significant traction due to its exceptional energy efficiency and structural integrity. According to a recent report by MarketsandMarkets, the global market for aluminum extrusions is projected to reach USD 100 billion by 2024, with thermal break applications playing a crucial role in this growth. The incorporation of thermal break technology not only enhances insulation but also contributes to sustainability by reducing energy consumption in buildings. As energy regulations become more stringent and the demand for eco-friendly solutions rises, sourcing high-quality Thermal Break Aluminum Extrusion has become imperative for manufacturers and builders alike. This blog will explore top strategies for effectively sourcing these critical components, ensuring that industry professionals can make informed decisions that align with both performance and environmental goals.

Thermal break aluminum extrusion is a pivotal component in modern architecture, designed to minimize heat transfer and enhance energy efficiency. One significant property of this material is its ability to reduce thermal bridging, which is crucial in maintaining indoor temperature stability. According to the U.S. Department of Energy, properly installed thermal break systems can enhance a building's energy efficiency by up to 40%, significantly lowering heating and cooling costs. This thermal efficiency not only contributes to sustainability goals but also promotes a comfortable living environment.

In addition to energy efficiency, thermal break aluminum extrusions offer durability and aesthetic flexibility. These materials are resistant to corrosion and weathering, which ensures longevity even in harsh climates. Industry reports, such as those from the Aluminum Association, indicate that the use of architectural aluminum can decrease maintenance costs by nearly 30% compared to traditional materials. With the growing emphasis on sustainable building practices, understanding these key properties and benefits of thermal break aluminum extrusion is essential for manufacturers and architects aiming to achieve high performance in their projects.

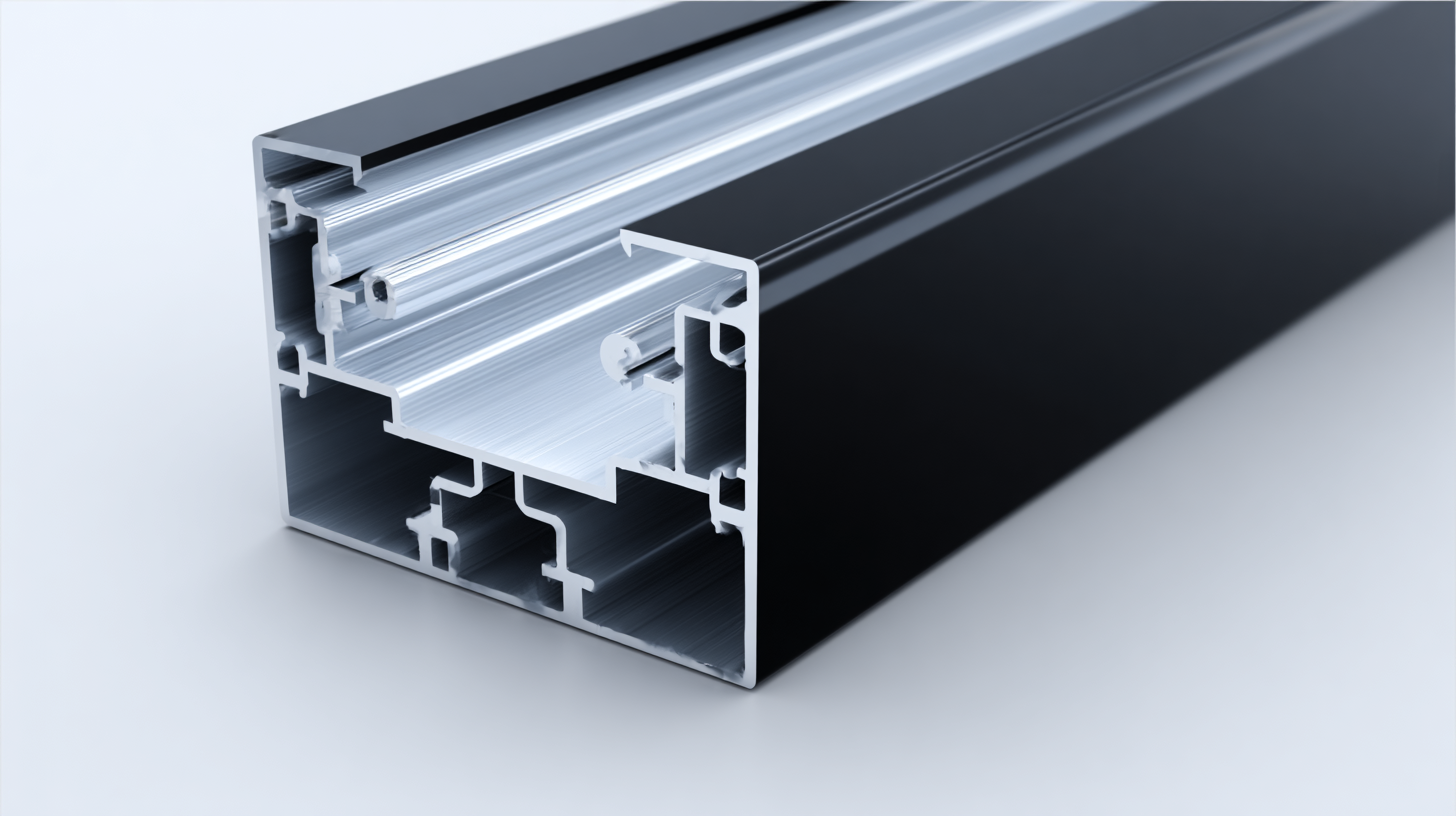

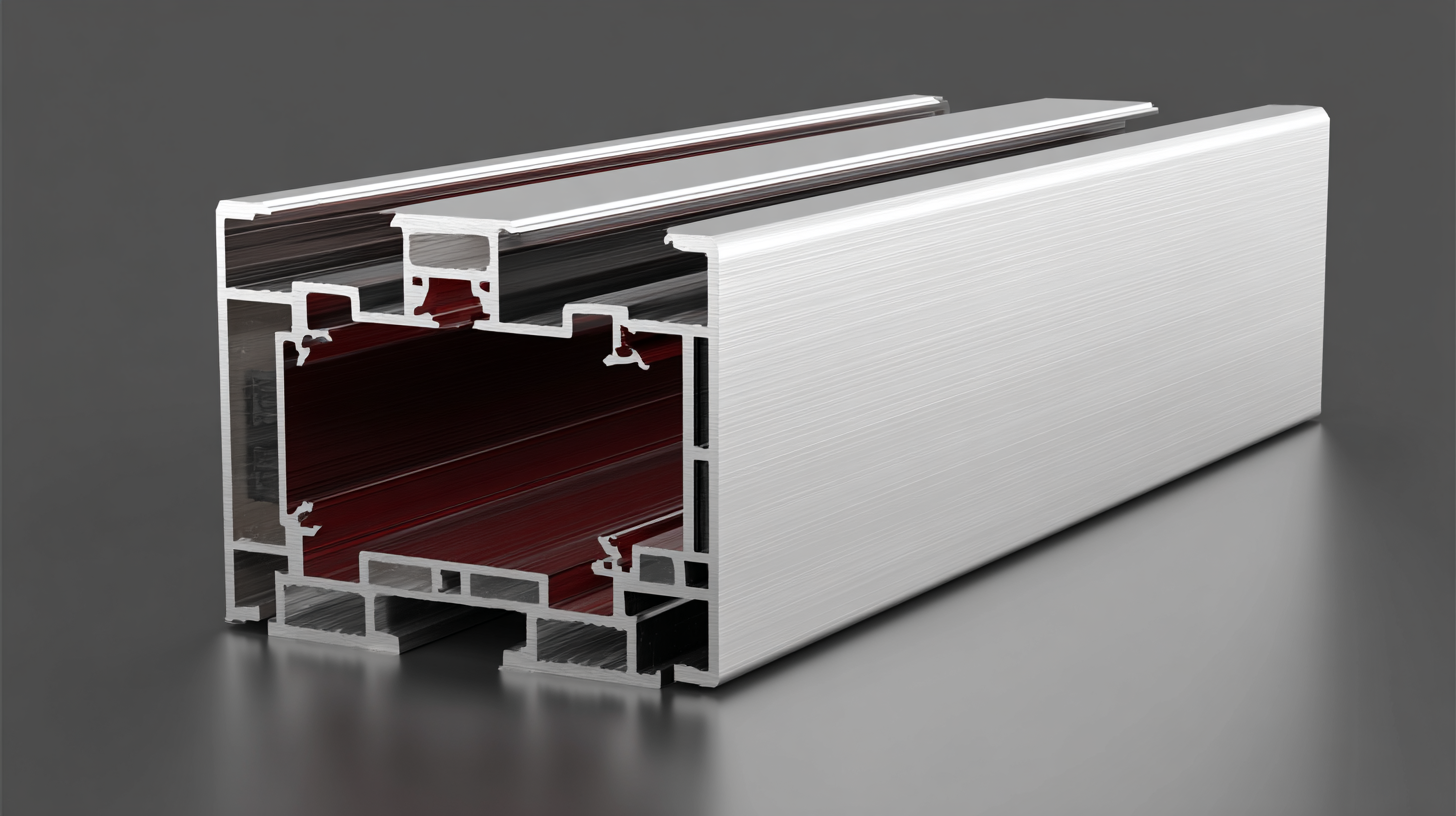

When sourcing high-quality thermal break aluminum products, it’s essential to understand the different types available in the market. The primary categories include

standard thermal break systems, which typically feature a polyamide or polyurethane barrier, and

enhanced systems that provide superior insulation properties. Knowing the specific requirements of your project

will help you select the right type, ensuring optimal performance and energy efficiency.

Tip: Always assess the thermal performance ratings and certifications of the products you're considering.

Look for materials that meet recognized standards, as this indicates a commitment to quality and reliability.

Another important factor to consider is the versatility of the thermal break aluminum products. Some systems are designed for residential applications, while others

cater to commercial buildings requiring robust structural integrity. Identifying the intended application will guide you in selecting the most suitable options.

Tip: Engage with suppliers to discuss your project needs; they can often provide insights into the best product

types and any upcoming innovations that might enhance your choices. This proactive approach will ensure you make informed decisions tailored to your specific needs.

Thermal break aluminum extrusion has become an essential component in various industries, particularly in construction and manufacturing. This technology provides significant insulation benefits, reducing thermal conductivity and enhancing energy efficiency. According to a recent report by the U.S. Department of Energy, buildings are responsible for nearly 40% of the nation's energy consumption, underscoring the need for effective thermal management solutions. The incorporation of thermal break aluminum extrusion in window frames, curtain walls, and facades can result in energy savings of up to 30%, making it a critical element for sustainable building practices.

In the automotive sector, thermal break aluminum extrusion plays a vital role in lightweighting and improving energy efficiency. A study by the International Aluminum Institute indicates that using aluminum components in vehicle design can reduce vehicle weight by approximately 50%, contributing to improved fuel efficiency and reduced emissions. Additionally, the aerospace industry is integrating this technology for its thermal and structural benefits, particularly in aircraft components where weight reduction and energy efficiency are paramount. The versatility and performance of thermal break aluminum extrusion are redefining standards across these diverse sectors, making it an indispensable material for modern engineering and design challenges.

When evaluating aluminum extrusion products, the performance difference between thermal break and non-thermal break options is striking. Thermal break aluminum extrusions incorporate an insulating material between the exterior and interior frames, significantly reducing heat transfer. This results in enhanced energy efficiency, particularly in climates with extreme temperatures. The reduced thermal conductivity not only helps maintain comfortable indoor conditions but also lowers heating and cooling costs, making these products particularly appealing for residential and commercial buildings.

On the other hand, non-thermal break aluminum extrusions are typically more affordable and certain designs may even have higher structural integrity. However, their lack of thermal insulation can lead to increased heat loss in winter months and heat gain during summer. This inefficiency can result in higher energy bills and less comfort over time. Ultimately, the choice between thermal break and non-thermal break aluminum products should be guided by specific project requirements, including climate consideration and budget constraints. Understanding these differences can help in making informed decisions that align with overall performance and energy efficiency goals.

When sourcing high-quality thermal break aluminum extrusions, it is essential to adopt best practices that ensure product reliability and performance. One significant factor is evaluating the manufacturing process employed by the extruder. According to industry reports, over 70% of defects in aluminum extrusions can be traced back to inadequate manufacturing techniques. Engaging with suppliers who utilize advanced technology such as CNC machining and automated cutting can dramatically enhance the quality assurance of the final product.

Furthermore, performing rigorous assessments of the extruder’s material sources can significantly impact the thermal performance of the aluminum profiles. Research indicates that extrusions made from high-grade aluminum alloys can reduce thermal conductivity by nearly 50%, enhancing the energy efficiency of structures. It is also beneficial to review certifications and compliance with industry standards to verify that the products meet necessary regulations.

The top aluminum extrusion companies prioritize these criteria, making them key players in delivering superior thermal break solutions to the market.