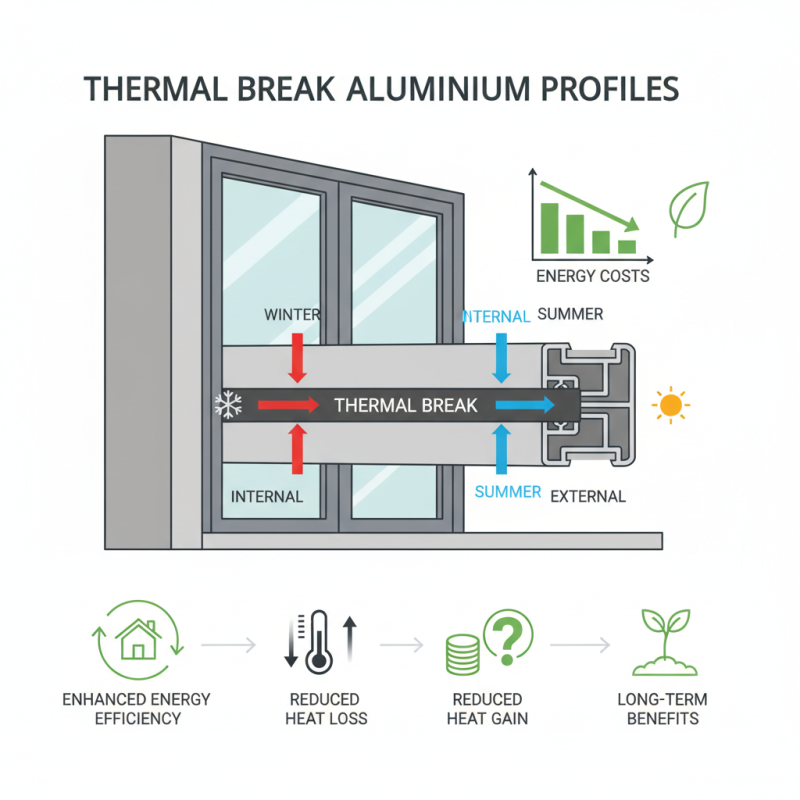

Thermal Break Aluminium Profiles are essential in modern architecture. They offer enhanced energy efficiency and comfort in buildings. By separating the internal and external environments, these profiles minimize heat transfer.

In regions with extreme climates, the importance of Thermal Break Aluminium Profiles becomes clear. They help reduce energy costs, making buildings more sustainable. The design involves a non-conductive section that acts as a barrier. This barrier prevents heat loss during winter and heat gain in summer.

However, it is crucial to remain critical of their limitations. Some may overlook the upfront costs associated with these profiles. Understanding their long-term benefits is essential for making informed decisions. Ultimately, Thermal Break Aluminium Profiles represent a blend of innovation and practicality in construction.

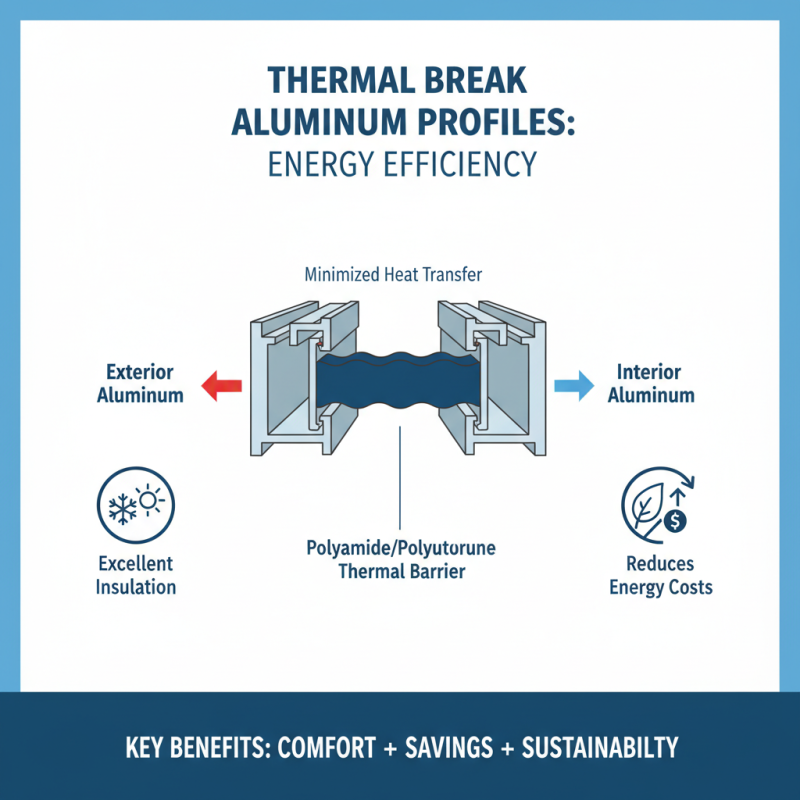

Thermal break aluminium profiles are an innovation in building materials. They serve a critical role in energy efficiency. These profiles are designed with a barrier that separates the conductive aluminium. This barrier prevents heat transfer, enhancing insulation.

Typically, thermal break profiles feature a nylon or polyurethane insert. This insert is placed between two pieces of aluminium. By doing this, the inner and outer sections remain at different temperatures. As a result, homes and buildings become more energy-efficient. Increased comfort is a notable outcome. Yet, the complexity of installation can raise challenges. If not done correctly, effectiveness diminishes.

Another aspect to consider is the durability of thermal break profiles. While they are designed to last, exposure to elements may impact performance over time. Regular maintenance is necessary to ensure their efficiency. Users sometimes overlook this aspect, leading to potential heat loss. Thus, being aware of these factors is crucial for sustainable building practices.

Thermal break aluminium profiles offer excellent insulation properties. They are designed with a non-conductive material separating two aluminium sections. This unique design minimizes heat transfer between indoors and outdoors. Generally, polyamide or polyurethane serves as the thermal break material, ensuring energy efficiency.

The composition of these profiles plays a crucial role in their performance. The outer aluminium skin provides strength and durability. Meanwhile, the inner core holds the thermal break insert. This combination ensures structural integrity while reducing energy loss.

However, not all thermal break profiles are equal. Manufacturing quality can vary. Poorly designed profiles may allow for thermal bridges. This can lead to condensation and mold issues. It's vital to assess the quality of materials used. Selecting profiles with good insulation properties is essential for long-term efficiency.

Thermal break aluminium profiles are designed to improve energy efficiency. They feature a layer of insulating material between two metal sections. This design minimizes heat transfer, helping keep spaces cooler in summer and warmer in winter.

The technology enhances comfort in buildings. By reducing the need for heating and cooling, it saves energy. You might notice less condensation on windows. This indicates improved insulation. Buildings can achieve lower energy bills with thermal break installations. However, some may overlook proper installation practices. Poor fitting can compromise energy efficiency. Buyers should consider details carefully.

In addition, awareness of maintenance is essential. Over time, seals and insulators can wear out. Regular checks can prevent future issues. It’s not just about installation; ongoing care matters too. Energy-efficient solutions like these can lead to sustainable living. Yet, the path to perfect implementation is complex and requires attention.

Thermal break aluminium profiles have gained popularity in the construction industry. These profiles reduce heat transfer, improving energy efficiency. They consist of two aluminium sections separated by a non-conductive material. This design minimizes thermal bridging and condensation.

In buildings, these profiles are used in windows and doors. They help maintain indoor temperatures, making spaces more comfortable. Additionally, they reduce energy costs, offering long-term savings for homeowners. Many architects appreciate the aesthetic appeal, as these profiles can be designed in various finishes.

However, not all thermal break aluminium profiles are created equal. Some may not perform well in extreme climates. It's essential to consider local weather conditions when selecting these materials. A balance between energy efficiency and durability must be sought, requiring careful planning and reflection during the design phase.

Thermal break aluminium profiles offer energy efficiency and comfort in buildings. They act as insulators, reducing heat transfer. This function helps maintain a stable indoor temperature. However, the effectiveness of thermal break systems depends on proper maintenance.

Regular inspection is vital. Look for signs of wear or damage. Small cracks can lead to larger issues. Clean the frames to prevent dirt accumulation. Dust can affect the insulation over time. Consider using a soft cloth and mild detergent. Avoid abrasive materials that may scratch the surface.

Tips for enhancing durability: Apply weatherstripping around the edges to minimize air leaks. Ensure good drainage systems are in place to prevent water buildup. Reseal joints when necessary. Proper maintenance prolongs the life of thermal break systems significantly. Keep records of inspections and repairs to track the health of your profiles. Over time, this can make a difference.

| Dimension | Description | Benefits | Maintenance Tips | Durability Rating |

|---|---|---|---|---|

| U-Value | Indicates thermal efficiency of profiles. | Improved energy efficiency and reduced heating costs. | Regular cleaning and inspection for cracks. | 5-20 years depending on use. |

| Material Composition | Aluminium with polymer inserts. | Corrosion resistance and optimal insulation. | Check seals and replace if needed. | 10-30 years based on environmental factors. |

| Weight | Lightweight compared to traditional materials. | Easier handling and installation. | Inspect for dents or damages. | 15-25 years with proper care. |

| Aesthetic Options | Variety of colors and finishes available. | Enhances building design and property value. | Regularly clean to maintain finish. | 10 years for color retention. |