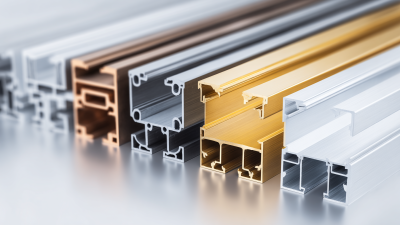

In the quest for energy-efficient buildings, architects and builders are increasingly turning to innovative materials that enhance thermal performance. One such solution is Thermal Break Aluminium Profiles, which play a critical role in minimizing heat transfer and improving insulation.

According to a report by the International Energy Agency (IEA), buildings account for nearly 40% of global energy consumption, making energy efficiency a top priority in construction practices. These advanced profiles incorporate a non-conductive material that separates interior and exterior aluminium, resulting in significantly lower U-values, which measure heat transfer efficacy.

The use of Thermal Break Aluminium Profiles not only boosts energy savings—reported to be up to 20% in some applications—but also contributes to environmentally sustainable design by reducing dependencies on heating and cooling systems. This blog will explore why these profiles are becoming the material of choice for energy-efficient buildings, outlining their benefits and applications in modern architecture.

The use of Thermal Break Aluminium Profiles not only boosts energy savings—reported to be up to 20% in some applications—but also contributes to environmentally sustainable design by reducing dependencies on heating and cooling systems. This blog will explore why these profiles are becoming the material of choice for energy-efficient buildings, outlining their benefits and applications in modern architecture.

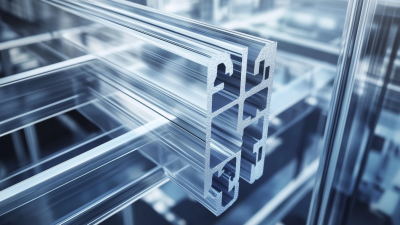

The concept of thermal break technology in aluminum profiles is a key player in enhancing energy efficiency in buildings. This technology involves creating a barrier between the interior and exterior frames, typically using a non-conductive material. This barrier minimizes heat transfer, effectively reducing energy loss during both heating and cooling seasons. As a result, buildings equipped with thermal break aluminum profiles experience improved insulation, leading to lower energy bills and a reduced carbon footprint. Such advancements not only contribute to individual comfort but also align with global sustainability goals.

In the broader context of energy efficiency, innovations in materials such as these are crucial for future-oriented designs. For instance, advancements in the recycling technology of other energy solutions, like photovoltaic solar panels, echo similar themes of sustainability and efficiency. Both thermal break aluminum profiles and improved recycling processes underscore the importance of responsible material management in the construction and energy sectors. As the demand for sustainable building practices grows, the integration of cutting-edge technologies in materials will become increasingly vital to achieving energy-efficient and eco-friendly structures.

Thermal break aluminium profiles have gained immense popularity in energy-efficient architecture, thanks to their revolutionary design and impressive benefits. One of the most significant advantages is their enhanced thermal performance, which helps to minimize heat transfer. By incorporating a thermal break, these profiles effectively reduce the energy loss that often occurs in traditional framing systems, ensuring that buildings stay warmer in winter and cooler in summer. This energy efficiency not only leads to a comfortable indoor environment but also significantly lowers energy bills over time.

Another crucial benefit is the increased durability and longevity of the materials used. Thermal break aluminium frames are resistant to weathering, corrosion, and general wear and tear, making them a cost-effective choice in the long run. Moreover, they require minimal maintenance, which is a significant advantage for both builders and homeowners looking for sustainable solutions. The aesthetic flexibility of thermal break aluminium profiles allows architects to create visually stunning designs while maximizing energy efficiency, making them a perfect fit for modern environmentally conscious buildings.

Thermal break aluminium profiles have become a crucial component in the quest for energy efficiency in modern buildings. These innovative profiles significantly reduce heat transfer between the interior and exterior environments, providing insulation that keeps indoor temperatures stable. By incorporating a non-conductive material in the middle of the aluminium frame, thermal break profiles effectively minimize thermal bridging, which is a common cause of energy loss. This design ensures that less energy is required for heating and cooling, leading to lower energy bills and a reduced carbon footprint.

Furthermore, the benefits of thermal break aluminium profiles extend beyond energy savings. They enhance the overall comfort of living spaces by maintaining consistent indoor temperatures and reducing drafts. This not only creates a more pleasant environment for occupants but also contributes to improved air quality by minimizing the need for excessive heating or cooling systems. As buildings evolve towards more sustainable and energy-efficient standards, the adoption of thermal break aluminium profiles is poised to play a vital role in shaping a greener future for architecture and construction.

When it comes to building energy-efficient structures, the choice of materials plays a crucial role. Thermal break aluminium profiles stand out when contrasted with traditional materials such as wood, steel, and unbroken aluminium. The defining feature of thermal break technology is its ability to minimize thermal bridging, which occurs when heat transfers through the material, leading to energy losses. In contrast, traditional materials often exhibit significant thermal conductivity, allowing heat to escape in winter and penetrate indoors during summer. As a result, buildings constructed with thermal break aluminium profiles offer superior insulation, contributing to reduced energy consumption and lower utility bills.

In addition to thermal performance, the durability and maintenance of materials are critical factors in construction. Traditional materials can be susceptible to weathering and require regular upkeep, which can be both time-consuming and costly. On the other hand, thermal break aluminium profiles are designed to withstand the elements, providing long-term performance without the need for extensive maintenance. Their resistance to corrosion and fading also ensures that energy-efficient buildings remain aesthetically pleasing over time. This combination of energy efficiency and low maintenance makes thermal break aluminium profiles an increasingly preferred choice for modern constructions aiming to meet sustainability goals.

| Criteria | Thermal Break Aluminium Profiles | Traditional Materials |

|---|---|---|

| Thermal Conductivity (W/mK) | 1.5 | 5.0 |

| Energy Efficiency Rating | A+ | B |

| Durability (Years) | 50+ | 30 |

| Maintenance Frequency (Years) | 10 | 5 |

| Weight (kg/m²) | 4.5 | 7.0 |

| Cost (per m²) | $75 | $50 |

Thermal break aluminium profiles have emerged as a revolutionary solution in modern building design, offering innovative applications that amplify energy efficiency and enhance aesthetic appeal. These profiles create a thermal barrier by separating the internal and external elements of windows, doors, and facades. This separation reduces heat transfer, thus minimizing energy consumption for heating and cooling, which is vital in today’s quest for sustainable architecture. By employing these profiles, architects can maintain comfortable indoor environments while reducing carbon footprints.

In addition to energy savings, thermal break aluminium profiles provide design flexibility that can accommodate a variety of architectural styles. Their sleek, modern design allows for expansive glazing options, maximizing natural light while maintaining structural integrity. Recently, these profiles have been utilized in creative ways, such as in curtain wall systems and innovative shading devices, which not only enhance building aesthetics but also optimize energy performance. As construction trends shift towards greener practices, thermal break aluminium stands out as a key material that supports both functionality and design sophistication, making it a go-to choice for energy-efficient buildings.