The Thermal Break Aluminum Profile is a crucial innovation in modern construction and design, serving as a vital solution for enhancing energy efficiency and insulation in buildings. As architects and builders strive to create structures that minimize thermal transfer, the use of this specialized aluminum profile has gained significant attention. By incorporating a thermal barrier within the aluminum frame, these profiles effectively reduce heat flow, thereby helping to maintain comfortable indoor temperatures and reducing energy consumption.

In an era where sustainability and energy efficiency are at the forefront of architectural considerations, understanding the importance of the Thermal Break Aluminum Profile becomes essential. It not only contributes to better thermal performance but also aids in compliance with increasingly stringent building codes and energy regulations. Moreover, the long-term benefits of using such profiles extend to improved occupant comfort and cost savings, making them an indispensable element in contemporary building practices. As we delve deeper into the significance of Thermal Break Aluminum Profiles, we will explore their composition, functionality, and the pivotal role they play in enhancing insulation in modern architecture.

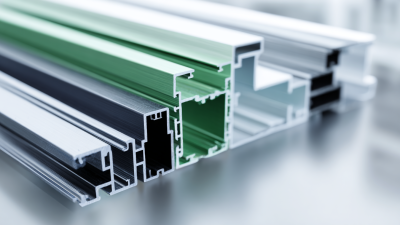

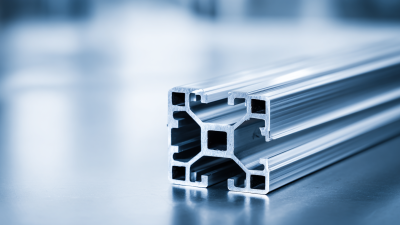

Thermal break aluminum profiles are essential components in modern construction, specifically designed to enhance insulation and energy efficiency. These profiles consist of two separate aluminum sections that are connected by a non-conductive material, usually a polymer. This innovative design minimizes thermal bridging, which occurs when heat transfers through the conductive metal, leading to energy loss. By utilizing thermal break technology, these profiles help maintain consistent indoor temperatures and reduce heating and cooling costs.

When considering thermal break aluminum profiles, it is important to understand their composition. The aluminum sections provide structural integrity and durability, while the thermal break material serves as a barrier to heat flow. Common materials used for the thermal break include polyurethane or polyamide, which possess low thermal conductivity. This combination effectively separates the interior from the exterior environments, significantly enhancing energy performance.

Tips: When selecting thermal break aluminum profiles for your project, look for options with high thermal resistance ratings. Additionally, ensure that they meet local energy efficiency standards, as these can vary by region. Proper installation is equally crucial; even the best profiles can underperform if not fitted correctly, so consider hiring experienced professionals to guarantee optimal results.

This bar chart displays the thermal conductivity values of different materials including standard aluminum, thermal break aluminum, wood, and PVC. Lower values of thermal conductivity indicate better insulation performance, making thermal break aluminum profiles essential for enhancing energy efficiency in buildings.

Thermal breaks play a crucial role in enhancing energy efficiency in buildings. These innovative features are designed to interrupt the flow of heat between the interior and exterior surfaces of a structure, significantly reducing thermal conductivity. This interruption is essential because it prevents unwanted heat transfer, which can lead to increased energy consumption for heating and cooling. By minimizing this transfer, thermal break aluminum profiles help maintain a stable indoor temperature, thus reducing the reliance on HVAC systems and lowering energy bills.

Incorporating thermal breaks into building design not only improves comfort but also contributes to a building's overall sustainability. By using materials that prevent heat loss, energy efficiency is improved, leading to a decreased environmental footprint. Buildings that effectively utilize thermal breaks can achieve better energy ratings, which is increasingly important in today’s market as energy conservation becomes a paramount concern.

As a result, thermal breaks are not just a structural enhancement; they are a vital component in the pursuit of energy-efficient and environmentally responsible architecture.

Thermal break aluminum profiles have gained significant popularity in modern architecture due to their superior insulation properties. These profiles are designed with an insulating material inserted between the interior and exterior components of aluminum frames, effectively reducing heat transfer. One of the primary advantages of using thermal break aluminum profiles is their ability to enhance energy efficiency in buildings. By significantly lowering thermal conductivity, these profiles help maintain stable indoor temperatures, reducing reliance on heating and cooling systems. This can lead to substantial energy savings over time, as well as a reduced carbon footprint.

Another key advantage of thermal break aluminum profiles is their contribution to improved comfort in living and working spaces. By minimizing cold and heat transfer, they prevent unpleasant drafts and temperature fluctuations, creating a more pleasant indoor environment. Additionally, these profiles are resistant to condensation, which can help mitigate moisture-related issues like mold growth and structural damage. The combination of enhanced insulation, increased comfort, and energy efficiency makes thermal break aluminum profiles an essential choice for architects and builders seeking sustainable and innovative building solutions.

Thermal break aluminum profiles are increasingly recognized for their vital role in construction, particularly when it comes to energy efficiency and insulation. These profiles are designed with an internal insulating material that minimizes heat transfer between the interior and exterior of a building. Consequently, they are particularly beneficial in applications where temperature control is essential, such as in residential and commercial buildings. By reducing thermal bridging, these profiles help maintain comfortable indoor temperatures while lowering energy consumption, making them a preferred choice for architects and builders aiming for sustainability.

In the construction sector, thermal break aluminum profiles find extensive application in windows, doors, and curtain walls. Their structural integrity combined with effective insulation properties makes them ideal for high-performance building envelopes, where aesthetics and functionality are both critical. For instance, in high-rise buildings, these profiles can significantly decrease the risk of condensation and mold growth, contributing to healthier indoor environments. Moreover, they are also employed in areas exposed to harsh weather conditions, ensuring durability while enhancing the overall energy efficiency of the building. As energy codes become stricter globally, the significance of these profiles will only continue to grow, promoting greener building practices.

When it comes to architectural designs and energy efficiency, the choice between thermal break and non-thermal break aluminum profiles is crucial. Thermal break aluminum profiles are designed with a non-conductive material that separates the internal and external Aluminum, significantly reducing heat transfer. According to a report by the Aluminum Association, buildings utilizing thermal break profiles can reduce energy consumption by over 30% compared to traditional aluminum systems. This energy efficiency translates not only into lower utility bills but also into a smaller carbon footprint, aligning with modern sustainability goals.

In contrast, non-thermal break aluminum profiles offer advantages in terms of cost-effectiveness and easier manufacturing. However, they fall short in thermal insulation performance. Research conducted by the American Architectural Manufacturers Association indicates that non-thermal break systems can lead to significant heat loss, contributing to higher energy usage and increased need for HVAC resources. The analysis reveals that while thermal break profiles may require a higher initial investment, their long-term benefits, including energy savings and enhanced comfort, make them the superior choice for eco-conscious construction projects. By opting for thermal break solutions, architects and builders can effectively address thermal bridging issues, thus ensuring a more efficient performance in both residential and commercial applications.