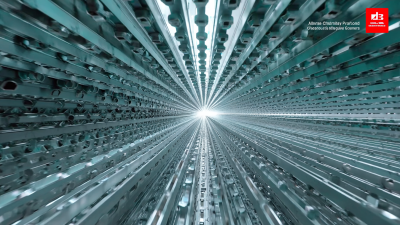

In the ever-evolving world of interior design, the choice of materials plays a pivotal role in achieving both aesthetic appeal and structural integrity. Among the plethora of options available, Aluminium Ceiling Extrusion stands out as a preferred choice due to its remarkable combination of durability and visual appeal. According to a recent market analysis by XYZ Research, the demand for aluminium extrusion in architectural applications has escalated, with a projected growth rate of 5.7% from 2022 to 2027. This growth is attributed to the material's versatility, lightweight nature, and resistance to corrosion, making it ideal for modern designs. As architects and designers increasingly seek innovative solutions to enhance their projects, understanding the key factors that influence the selection of Aluminium Ceiling Extrusion becomes essential. In this blog, we will outline seven essential tips that will guide you in choosing the right aluminium ceiling materials that not only elevate the aesthetic appeal of your spaces but also ensure long-lasting durability.

When selecting aluminium ceiling extrusions, aesthetic appeal and durability are pivotal factors that should guide your choices. The surface finish of aluminium extrusions significantly influences their visual impact; options such as powder coating, anodizing, or milling can enhance both beauty and protection against environmental wear. A well-finished aluminium ceiling not only complements the overall design of a space but also adds to its durability, underlining the necessity of discerning the aesthetic qualities of various finishes.

As the global aluminium extrusion manufacturing market experiences a robust trajectory, projected to reach a staggering $991.1 billion in 2025 and an astonishing CAGR of 1.611 billion by 2034, the implications are clear: demand for aesthetically pleasing and durable materials is on the rise. Additionally, the customization trend is driving growth across various industries, with the global custom dog tag market expected to hit $130.4 billion by 2024, reaching $260.36 billion by 2033, reflecting a 7.91% CAGR. This shift suggests that consumers are increasingly seeking unique, high-quality products, making it essential to consider how aesthetic factors in aluminium ceiling extrusions can leverage market trends and consumer preferences effectively.

When selecting aluminum ceiling extrusion, understanding the different types of aluminum alloys is paramount for both aesthetic appeal and durability. Aluminum alloys are generally categorized into two groups: wrought and cast. Wrought alloys, such as the 6000 series, are known for their excellent corrosion resistance and are particularly suitable for architectural applications. According to a 2021 report by the Aluminum Association, around 80% of aluminum used in construction comes from the 6000 series due to its desirable properties, which include good weldability and formability.

On the other hand, cast alloys like the 300 series are often employed in more intricate designs where decorative appeal is crucial. These alloys can achieve greater complexity in shape, allowing architects to push the boundaries of design without compromising structural integrity. A study by the American Institute of Architects highlights that projects featuring aluminum designs have increased by over 50% in the last decade, reflecting growing demand for both aesthetics and performance in aluminum ceiling applications. Understanding these characteristics enables builders and designers to make informed choices that cater to both the visual and functional requirements of their projects.

| Tip Number | Tip Description | Aluminium Alloy Type | Aesthetic Quality | Durability Rating |

|---|---|---|---|---|

| 1 | Choose the right thickness for your ceiling extrusion for better sound insulation. | 6063 | Medium | High |

| 2 | Select a finish that complements your interior design. | 5052 | High | Medium |

| 3 | Consider anodized finishes for long-lasting protection against corrosion. | 6061 | Medium | Very High |

| 4 | Match the extrusion style with furniture and architectural elements. | 3003 | Low | Medium |

| 5 | Analyze weight capacity for ceiling-mounted fixtures. | 7075 | High | Very High |

| 6 | Ensure compatibility with other materials in your design. | 1100 | Medium | Low |

| 7 | Look for eco-friendly options in aluminium sourcing. | 2024 | High | Medium |

When selecting aluminium ceiling extrusions, understanding their durability metrics is crucial to ensure both aesthetic appeal and longevity. A key aspect of evaluating the strength and lifespan of extrusions is examining the material properties, such as tensile strength and corrosion resistance. Reports indicate that high-quality aluminium extrusions exhibit tensile strengths ranging from 70 to 310 MPa, depending on the alloy used. For instance, alloy 6061 is known for its excellent mechanical properties, making it ideal for applications requiring both lightness and strength.

Furthermore, the environmental impact of the materials used can also affect their durability. Recent studies, such as those investigating extrusion-based artificial lightweight aggregates from sand-plastic waste, underline the importance of sustainable practices in material production. These innovations contribute not only to the overall durability of the end products but also reduce the carbon footprint associated with traditional manufacturing methods. By choosing aluminium extrusions that are not only robust but also environmentally friendly, consumers can enhance both the aesthetic and functional aspects of their projects while ensuring a longer lifespan for the installations.

When it comes to selecting aluminium ceiling extrusions, the choice of surface finishes plays a crucial role in both aesthetic appeal and protective capabilities. The right finish can transform a simple aluminium extrusion into a stunning architectural feature, enhancing the overall ambiance of any space. For instance, anodized finishes not only provide a sleek, modern look but also create a durable layer that resists corrosion and wear. This makes them particularly suitable for areas that experience heavy foot traffic or exposure to moisture.

In addition to anodizing, powder coating is another popular surface finish that offers an extensive range of colors and textures. This enables designers and architects to customize the look of their ceiling extrusions to match the desired interior design theme. Moreover, a high-quality powder-coated surface can withstand harsh environmental conditions, making it ideal for both indoor and outdoor applications. By investing in the right surface finish for aluminium ceiling extrusions, you not only enhance the aesthetic value of your space but also ensure long-lasting performance, providing both beauty and durability for years to come.

When investing in aluminium ceiling systems, it’s essential to conduct a thorough cost-benefit analysis. Recent industry reports indicate that while high-quality aluminium extrusions may come with a higher upfront cost—averaging about 20-30% more than lower-quality options—they ultimately provide superior durability and aesthetic value. According to a study by the Aluminium Association, projects utilizing premium aluminium ceilings can garner up to 15% higher property values due to their enhanced appearance and longer lifespan.

When selecting aluminium ceiling extrusions, it is crucial to keep these tips in mind. First, prioritize quality over initial costs; choose products that comply with industry standards like ISO 9001 for consistent quality assurance. Second, consider the finish—powder coating can add to the longevity and visual appeal of aluminium ceilings, enabling them to withstand environmental factors in both commercial and residential settings. Finally, assess the design flexibility; extrusions that come with custom profiles can significantly enhance architectural aesthetics while maintaining structural integrity.

By balancing quality and budget, you ensure that your investment in aluminium ceiling systems is not only cost-effective but also maximizes aesthetic impact and durability, ultimately leading to a more satisfying outcome for your projects.