Selecting the right Extrusion Aluminum Profiles is crucial for project success. The global aluminum extrusion market is projected to reach $40 billion by 2025. This rapid growth underscores the importance of making informed decisions.

Choosing the right profiles impacts both functionality and overall cost. Various industries, from automotive to construction, rely on these materials. However, many companies overlook key factors when selecting extrusion profiles. Subpar choices may lead to performance issues or increased expenses.

Understanding the specifications, tolerances, and finishing options is vital. Each profile can significantly affect assembly and durability. It is essential to address common pitfalls during this decision-making process. Seek improvements by analyzing past selections and outcomes. The quality of Extrusion Aluminum Profiles shapes not only the product but also influences the business's reputation.

Extrusion aluminum profiles are versatile in their applications. They are used in construction, manufacturing, and even consumer goods. These profiles come in various shapes and sizes, allowing for different uses. For example, a T-slot design can create simple frameworks. On the other hand, curved profiles may be suitable for aesthetics in modern architecture.

Choosing the right profile involves understanding specific needs. Consider the environment where it will be used. Profiles in outdoor settings must resist corrosion. The weight of the profile matters too. A lighter profile may suffice in non-load-bearing applications. However, for structural supports, strength becomes essential.

Envision the end use. What are the requirements? Is flexibility important? Reflecting on these aspects can lead to better decision-making. A profile that looks appealing may not always be functional. Balancing design with practical use is crucial. There may be times when you overlook essential factors, leading to regrets later. Learning from these experiences can refine future choices.

This chart illustrates the popularity of different aluminum profile applications based on industry needs. The data indicates the percentage of usage across various sectors such as construction, automotive, and electronics, assisting in understanding market trends.

Choosing the right aluminum alloy is crucial for extrusion projects. Different alloys have distinct characteristics that affect performance and durability. For instance, the 6061 alloy is known for its excellent corrosion resistance and weldability. It is widely used in structural applications. In contrast, 6005 is preferred for its higher strength and is often found in architectural features.

Industry reports suggest that nearly 60% of extrusion applications rely on 6061 and 6063 alloys. These two alloys provide flexibility in design while ensuring structural integrity. However, not all projects fit these profiles perfectly. Some projects may require alloys such as 7075 for higher strength-to-weight ratios. Yet, choosing a more complex alloy could complicate the extrusion process.

In addition, factors like heat treatment and formability play vital roles in alloy selection. Overlooking these aspects can lead to increased costs and production delays. Many engineers report encountering challenges when trying to match project specifications with available materials. Often, compromises must be made. Finding the right balance between cost, strength, and corrosion resistance is an ongoing challenge in the industry.

When selecting extrusion aluminum profiles, evaluating the design and structural requirements is crucial. The strength and durability of aluminum profiles can vary based on their design. According to a study by the Aluminum Association, around 20% of structural failures in aluminum applications arise from inadequate design considerations. Choosing the right profile requires careful analysis of load-bearing capacity.

Consider the specific application and environmental conditions. A profile used in a coastal area may need better corrosion resistance. Data shows that aluminum tailored for coastal environments can maintain integrity longer than standard profiles. Engineers often use software tools to simulate stresses, ensuring that the selected profile meets safety standards. However, reliance on simulations alone can lead to oversights.

It’s also essential to assess weight restrictions. Lightweight profiles may be beneficial for transport and installation, yet can compromise strength. Balancing weight and performance can prove challenging. In some cases, manufacturers recommend profiles that exceed minimum strength requirements for added safety. Ultimately, a reflective approach to design requirements can enhance the reliability and usability of aluminum profiles in various applications.

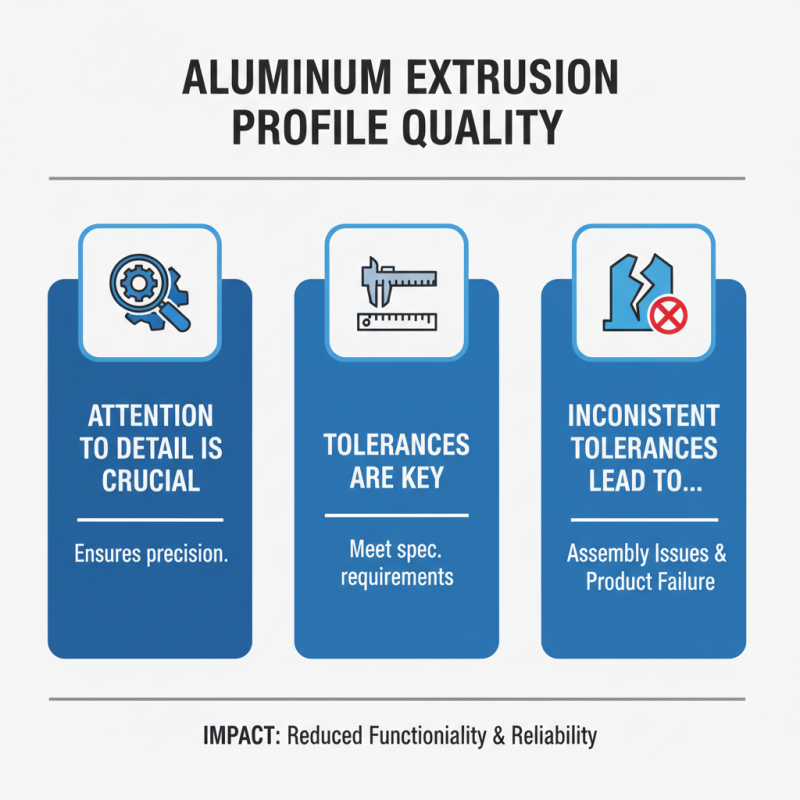

When assessing the manufacturing quality of extrusion aluminum profiles, attention to detail is crucial. Tolerances play a significant role in ensuring that the profiles meet specific requirements. Inconsistent tolerances can lead to assembly issues or final product failure, affecting overall functionality.

One tip is to review the supplier’s quality control processes. Reliable manufacturers often have stringent measures in place. These can include routine inspections and certifications. Additionally, consider the materials used in the extrusion process. High-quality aluminum alloys yield better performance and durability over time.

Examining surface finishes is another aspect. An uneven finish may indicate poor manufacturing. Defects like scratches or dents can compromise the integrity of the profiles. Always request samples for firsthand evaluation. This practice offers a tangible feel of the product’s quality. Remember, choosing the right profile requires vigilance in assessing both manufacturing quality and tolerances.

When planning an aluminum profile project, cost considerations are crucial. The price of aluminum fluctuates based on global market trends. Reports indicate that the average price per ton can range significantly, typically between $1,800 and $2,500. Projects must account for these variations.

Budgeting effectively involves more than just material costs. Fabrication, transportation, and labor can add 40-60% to the initial material expenses. This means a project estimated at $10,000 for materials could balloon to $14,000 or more, once all factors are considered.

Unexpected costs often emerge too. The complexity of the design can impact production time. Longer lead times can delay projects and increase costs. Reviewing your specifications and allowing flexibility might help avoid these pitfalls. Choosing profiles that can be easily produced and integrated into your designs may minimize risks and save money in the long run.

| Dimension | Material Thickness (mm) | Profile Type | Unit Cost (per meter) | Estimated Quantity | Total Cost Estimate |

|---|---|---|---|---|---|

| 20x20 | 1.5 | Square | $5.00 | 100 | $500.00 |

| 30x20 | 2.0 | Rectangular | $6.50 | 150 | $975.00 |

| 40x40 | 3.0 | Square | $8.00 | 80 | $640.00 |

| 50x25 | 2.5 | Rectangular | $7.00 | 120 | $840.00 |