In today's rapidly evolving manufacturing landscape, the significance of selecting the right Aluminium Extrusion Profile for your project cannot be understated. According to research conducted by the Freedonia Group, the global aluminium extrusion market is expected to reach a value of $60 billion by 2024, driven by growing demand across various sectors such as construction, automotive, and aerospace. This demand highlights the critical role that appropriate aluminium profiles play in ensuring structural integrity, weight efficiency, and design versatility. Given that every project comes with its own unique challenges, understanding the nuances of different aluminium extrusion profiles is essential for engineers and designers alike. This guide aims to provide a comprehensive overview of the key considerations, best practices, and industry insights needed to make informed decisions when selecting the ideal aluminium extrusion profile that meets your specific requirements.

Selecting the right aluminium extrusion profile is crucial for the success of any project, and understanding the basics is the first step towards making an informed decision. Aluminium extrusion, a process where aluminium is shaped into a desired cross-sectional profile, allows for lightweight yet strong components that can be tailored to specific applications. According to a report by the Aluminum Association, the global aluminium extrusion market is projected to reach approximately $48 billion by 2026, indicating a growing reliance on these profiles in various industries, including construction, automotive, and consumer goods.

When assessing aluminium extrusion profiles for your project, factors such as strength-to-weight ratio, corrosion resistance, and thermal conductivity come into play. For instance, the North American Aluminium Extruders Council states that aluminium’s strength-to-weight ratio can be up to three times greater than that of steel, making it an ideal choice for applications requiring both durability and weight savings. Additionally, the versatility in design and the ease with which aluminium can be machined or assembled further enhance its appeal. Understanding these fundamentals will empower project managers and engineers to choose profiles that best align with their project objectives, ensuring optimal performance and longevity.

When selecting the right aluminium extrusion profile for your project, there are several key factors to consider that can significantly influence your end results. First and foremost, you should evaluate the intended application of the profile. Different projects may require distinct mechanical properties, such as strength, flexibility, or weight. For instance, profiles used in structural applications need to be robust, while those for decorative purposes might prioritize aesthetics and finish. Understanding the specific demands of your project ensures that you choose an extrusion that can uphold necessary performance standards.

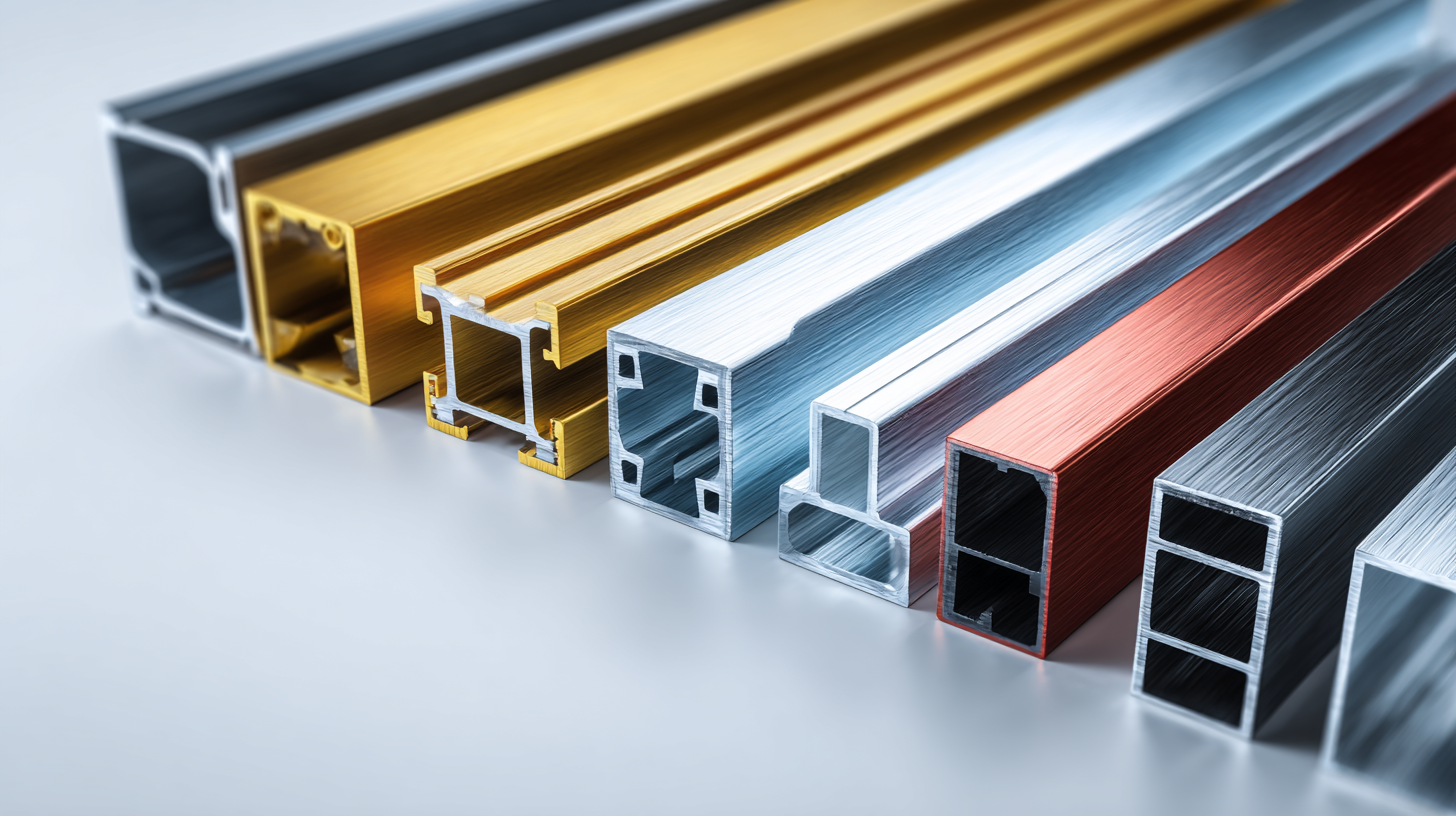

Another crucial consideration is the fabrication and machining capabilities of the aluminium profile. Assess the complexity of your design and whether the extrusion can accommodate features like bends or cuts without compromising its integrity. Additionally, consider the finishing processes required, such as anodizing or powder coating, which can enhance corrosion resistance and overall appearance. Finally, keep in mind the cost-effectiveness of the chosen profile. Balancing high-quality material and manufacturing efficiency will ultimately lead to a successful project execution while staying within budget constraints.

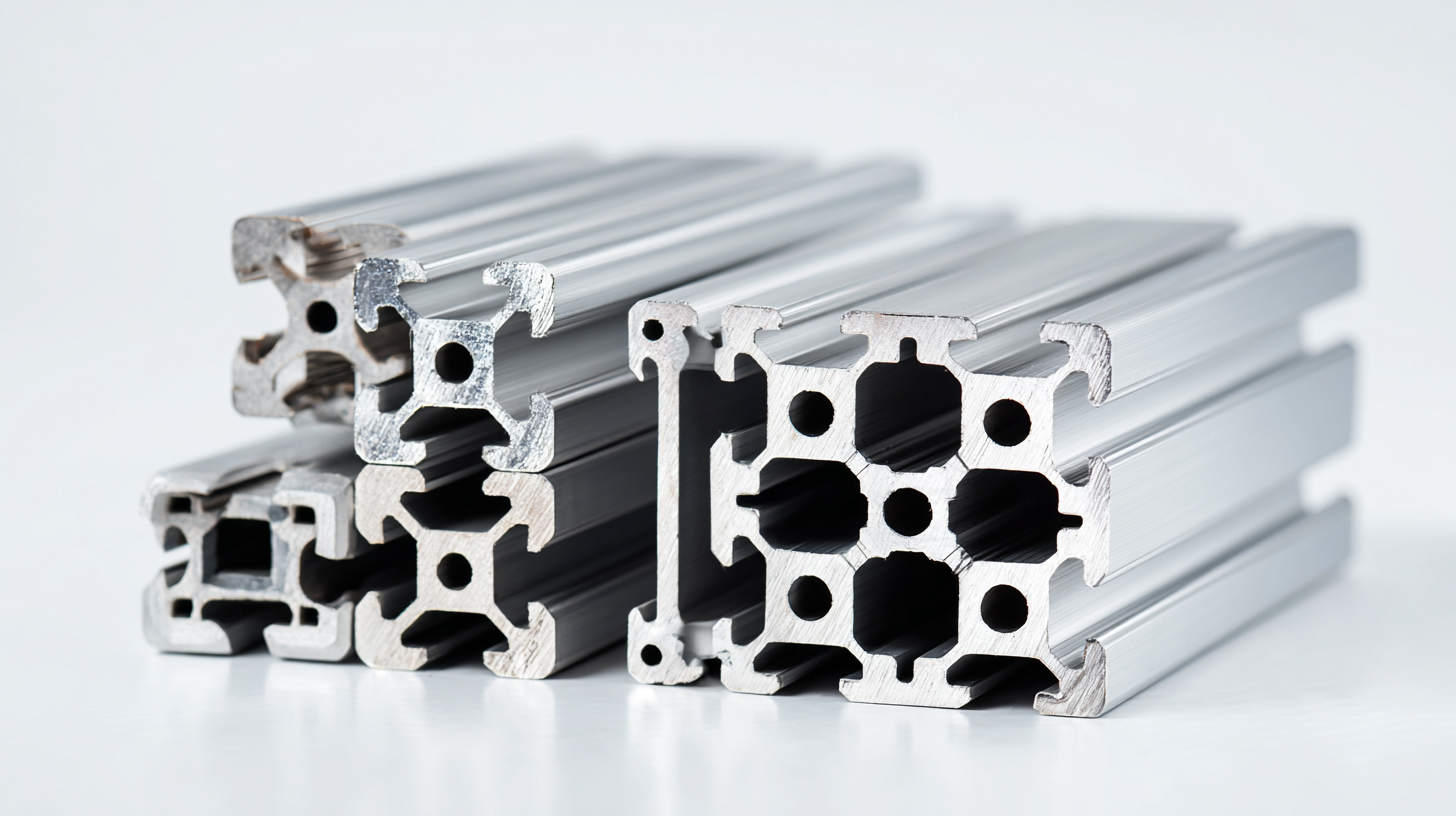

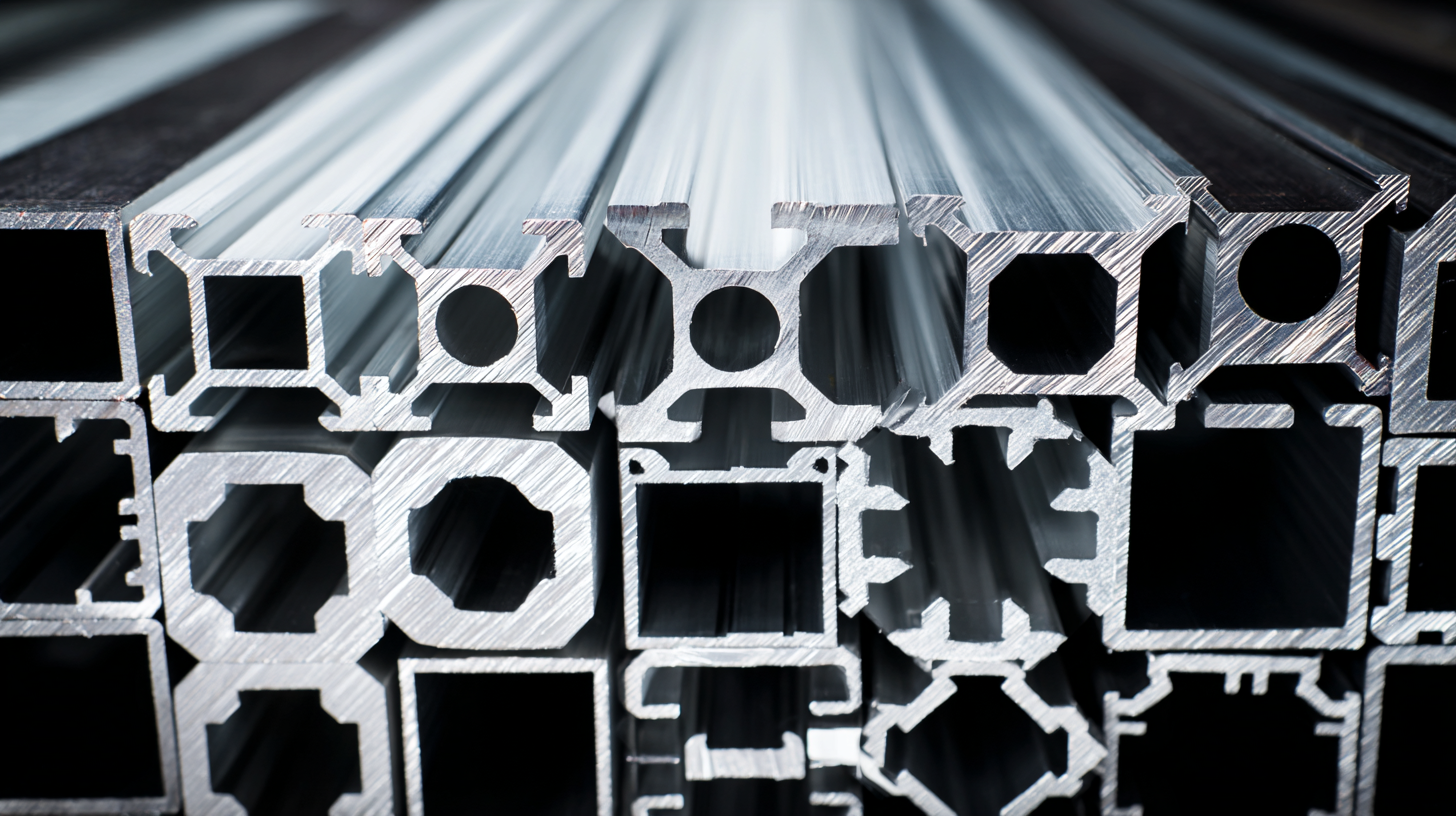

When selecting the right aluminium extrusion profile for your project, it's essential to understand the various types available and their specific applications. Aluminium extrusions can be broadly categorized into four key types: standard profiles, custom profiles, structural profiles, and architectural profiles. According to a 2021 report by the Aluminium Association, the demand for custom aluminium profiles has seen a significant increase, growing at a rate of 6% annually, as industries move towards more tailored solutions.

Standard profiles, including angles, channels, and tubes, often serve general-purpose applications, whereas structural profiles are designed for load-bearing applications in construction and manufacturing. Architectural profiles, on the other hand, are specifically crafted for aesthetic purposes, commonly used in facades and window frames, contributing to about 25% of the total aluminium extrusion market in recent years. This highlights the versatility of aluminium extrusions and their importance in modern engineering and design.

Moreover, advancements in technology, such as precision extrusion and surface treatment techniques, have enhanced the performance and appeal of these profiles. The global aluminium extrusion market size was valued at approximately $41.5 billion in 2022, with a projected compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, signaling a robust future for these applications across various industries. Understanding these profiles and their capabilities can significantly impact the success of your projects.

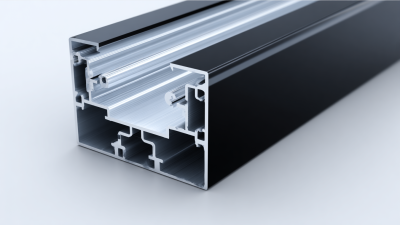

When selecting aluminium extrusion profiles for your project, evaluating the quality and durability of these materials is paramount. One of the key factors to consider is the alloy composition. Different alloys provide varying levels of strength, corrosion resistance, and suitability for specific applications. For instance, 6061 and 6063 aluminium alloys are popular choices; the former offers higher strength, while the latter is often used for architectural applications due to its excellent finish. It's essential to assess the specific needs of your project to choose an alloy that will perform effectively in its intended environment.

Another crucial aspect to evaluate is the manufacturing process of the aluminium profiles. High-quality extrusion involves controlled heating and cooling processes that promote uniformity and integrity within the final product. Techniques such as anodizing further enhance durability by creating a protective oxide layer that increases corrosion resistance and enhances surface hardness. Additionally, inspecting for any defects like surface irregularities or dimensional inaccuracies can help ensure that the profiles meet high-quality standards and will withstand the rigors of their intended use. Prioritizing these factors will lead to a successful selection of aluminium profiles that align with your project's requirements.

| Profile Type | Material Thickness (mm) | Weight (kg/m) | Yield Strength (MPa) | Surface Treatment | Applications |

|---|---|---|---|---|---|

| Square Tube | 3.0 | 4.0 | 220 | Anodized | Construction, Framing |

| Rectangular Tube | 4.0 | 6.5 | 235 | Powder Coated | Furniture, Automotive |

| Channel | 5.0 | 8.0 | 240 | Anodized | Railings, Supports |

| Angle | 3.5 | 5.0 | 250 | Mill Finish | Bracing, Frames |

| Round Tube | 2.5 | 3.5 | 210 | Brushed Finish | Piping, Handrails |

When budgeting for your aluminum extrusion project, understanding the costs associated with various aspects, including setup and processing, is crucial. Recent insights from an industry report outline the significant expenses tied to establishing an aluminum anodizing processing plant. The initial setup costs can vary widely, with estimates ranging from hundreds of thousands to millions of dollars depending on the scale and equipment chosen. This investment is essential for projects aiming for high durability and aesthetics in their aluminum profiles.

In addition to setup, operational costs must also be factored into your budget. These can include machinery maintenance, labor, and materials. The report notes that the automation of processes can lead to increased efficiency and reduced long-term costs, making it a worthy investment for many manufacturers. Understanding these elements will help you create a comprehensive budget, ensuring that your project not only meets technical specifications but also remains financially viable. Investing the time to analyze these costs can lead to better resource allocation and project success.