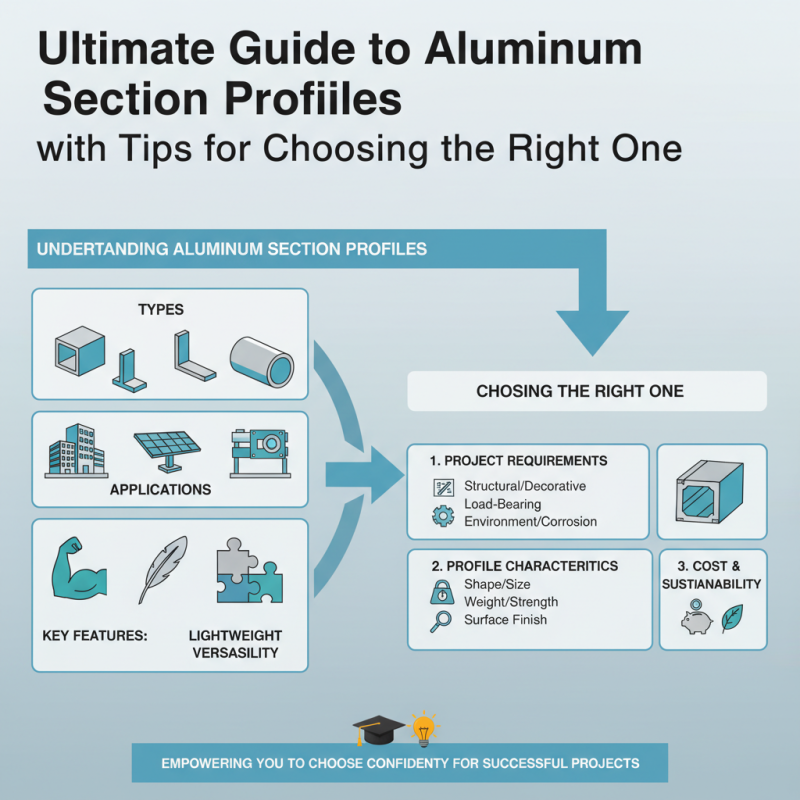

In the world of construction and manufacturing, selecting the right materials is crucial for the success and longevity of a project. Among these materials, Aluminum Section Profiles stand out as an increasingly favored choice due to their versatility, strength, and lightweight characteristics. With a myriad of options available, navigating the variety of aluminum profiles can be overwhelming, especially for those new to the industry. This ultimate guide is designed to demystify Aluminum Section Profiles, providing insights into their types, applications, and key features that make them ideal for various projects.

Understanding the specific requirements of your project is essential in making an informed choice about aluminum profiles. From structural framing to decorative elements, each application demands a unique set of characteristics that different aluminum sections can provide. Throughout this guide, we will share valuable tips and criteria to consider when choosing the appropriate Aluminum Section Profiles, ensuring that you select the options best suited to your needs. Whether you're a seasoned professional or a novice, this guide aims to equip you with the knowledge necessary to confidently choose the right aluminum profiles for your endeavors, paving the way for successful and sustainable construction solutions.

Aluminum section profiles are integral in various industries, offering versatility in applications ranging from construction to manufacturing. Understanding these profiles involves recognizing their structural efficiency and lightweight properties, which significantly contribute to reducing costs and enhancing performance. According to a recent industry report by Grand View Research, the global aluminum profile market was valued at approximately $79 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of around 8% through 2030. This growth signifies the increasing preference for aluminum in large-scale applications, including architectural frameworks and automotive parts.

When selecting the right aluminum section profile, consider the specific application requirements such as load-bearing capacity and environmental resistance. For instance, profiles with thicker walls offer increased durability for heavy-duty applications. Tip: Always refer to the latest material specifications and mechanical properties—this will ensure the chosen profile aligns correctly with performance requirements. Furthermore, it's crucial to factor in the finishing process, as anodizing or powder coating can enhance corrosion resistance and surface finish, further extending the lifespan of the product.

Tip: Engaging in discussions with suppliers can provide insights into the latest advancements in aluminum profiles, as they can offer expertise on which profiles will meet design aspirations and budget constraints. By thoroughly understanding the applications and utilizing informed approaches to selection, businesses can maximize the benefits of aluminum section profiles effectively.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Common Applications | Notes |

|---|---|---|---|---|

| Square Tube | 20 x 20 | 0.7 | Frameworks, Furniture | Easy to cut and join |

| Rectangular Tube | 40 x 20 | 1.1 | Construction, Automotive | High strength-to-weight ratio |

| L-Shape Profile | 30 x 30 | 0.9 | Supports, Brackets | Versatile and durable |

| T-Profile | 40 x 40 | 1.5 | Structural beams, Fences | Ideal for heavy loads |

| Channel | 100 x 50 | 2.0 | Carrying loads, Railings | Provides good rigidity |

When selecting aluminum section profiles, several key factors play a crucial role in determining the best fit for your project. One primary consideration is the intended application of the profile. Whether for structural support, architectural design, or custom fabrication, understanding the specific needs of your project will help narrow your options. Profiles come in various shapes, sizes, and thicknesses, so evaluating load-bearing requirements and compatibility with other materials is essential for achieving the desired performance.

Another important factor is the environmental conditions the aluminum will be exposed to. If your project will be subject to harsh weather, corrosive elements, or extreme temperatures, selecting the right alloy and finish becomes critical. Anodized or powder-coated finishes can enhance durability and corrosion resistance, ensuring the longevity of the profiles in challenging environments. Additionally, budgetary considerations and manufacturing capabilities should also be taken into account, as these aspects can significantly influence the overall feasibility and cost-effectiveness of the chosen aluminum section profiles.

Aluminum section profiles are widely used in various industries due to their lightweight, durability, and corrosion resistance. Understanding the common types and their features is essential for selecting the right one for your project. One of the most prevalent types is the square and rectangular tube profile, characterized by its robust design that allows for significant load-bearing capabilities. According to a report from the Aluminum Association, these profiles are often favored in structural applications due to their excellent strength-to-weight ratio, making them a cost-effective solution over alternatives like steel.

Another common profile is the T-slot, which offers versatility in assembly and is particularly popular in modular construction and manufacturing setups. T-slot profiles enable easy adjustments and adaptations, which is crucial in dynamic production environments. A study by Miller and Associates indicates that the use of T-slot profiles can reduce assembly time by up to 30%, enhancing overall productivity. Additionally, L-shaped sections are often utilized for structural support and frames, providing stability while allowing for easy attachment to other components.

When choosing an aluminum section profile, it is important to consider factors like load requirements, environmental conditions, and the specific applications. For example, anodized finishes can enhance corrosion resistance, making certain profiles more suitable for outdoor applications. Understanding these features not only facilitates better decision-making but also ensures optimal performance and longevity of the materials used in various constructions.

When it comes to fabricating and installing aluminum section profiles, adhering to best practices is crucial for achieving structural integrity and longevity. According to a recent industry report by the Aluminum Association, projects that follow established fabrication protocols can reduce post-installation adjustments by up to 30%. This remarkable statistic highlights the importance of using precision tools and trained personnel to ensure each section is cut, welded, and finished according to specifications.

One of the key tips for successful aluminum section installation is to maintain a clean working environment. Contaminants such as dust and oils can adversely affect the bonding process when joining sections. Additionally, selecting the right fasteners is essential; non-corrosive materials like stainless steel are recommended to ensure longevity and strength in various environments. It's advisable to conduct a thorough inspection of all components before installation to avoid costly rework later.

Another vital aspect is the consideration of thermal expansion. Aluminum can expand and contract significantly with temperature changes, which can lead to issues if not properly accounted for in the design. Allowing for expansion gaps in the installation can prevent structural stress and potential failure. Following these best practices not only enhances the durability of the installation but also ensures compliance with safety standards prevalent in the industry.

To ensure the longevity of aluminum section profiles, proper maintenance plays a crucial role. Regular cleaning is essential to prevent the accumulation of dirt and debris, which can cause surface corrosion over time. A simple solution of mild soap and water, applied with a soft cloth or sponge, can effectively remove grime without scratching the surface. It is advisable to rinse thoroughly with clean water to avoid residue and maintain the aesthetic appeal of the aluminum.

In addition to regular cleaning, inspecting aluminum section profiles for signs of wear or damage is important. Look for any scratches, dents, or areas of discoloration that could indicate potential issues. If such signs are detected, timely touch-ups or repairs can prevent further deterioration. Moreover, applying a protective coat or sealant can enhance the profile’s resistance to environmental factors, such as moisture and UV exposure. By following these maintenance tips, users can extend the lifespan of their aluminum section profiles and keep them looking new for years to come.