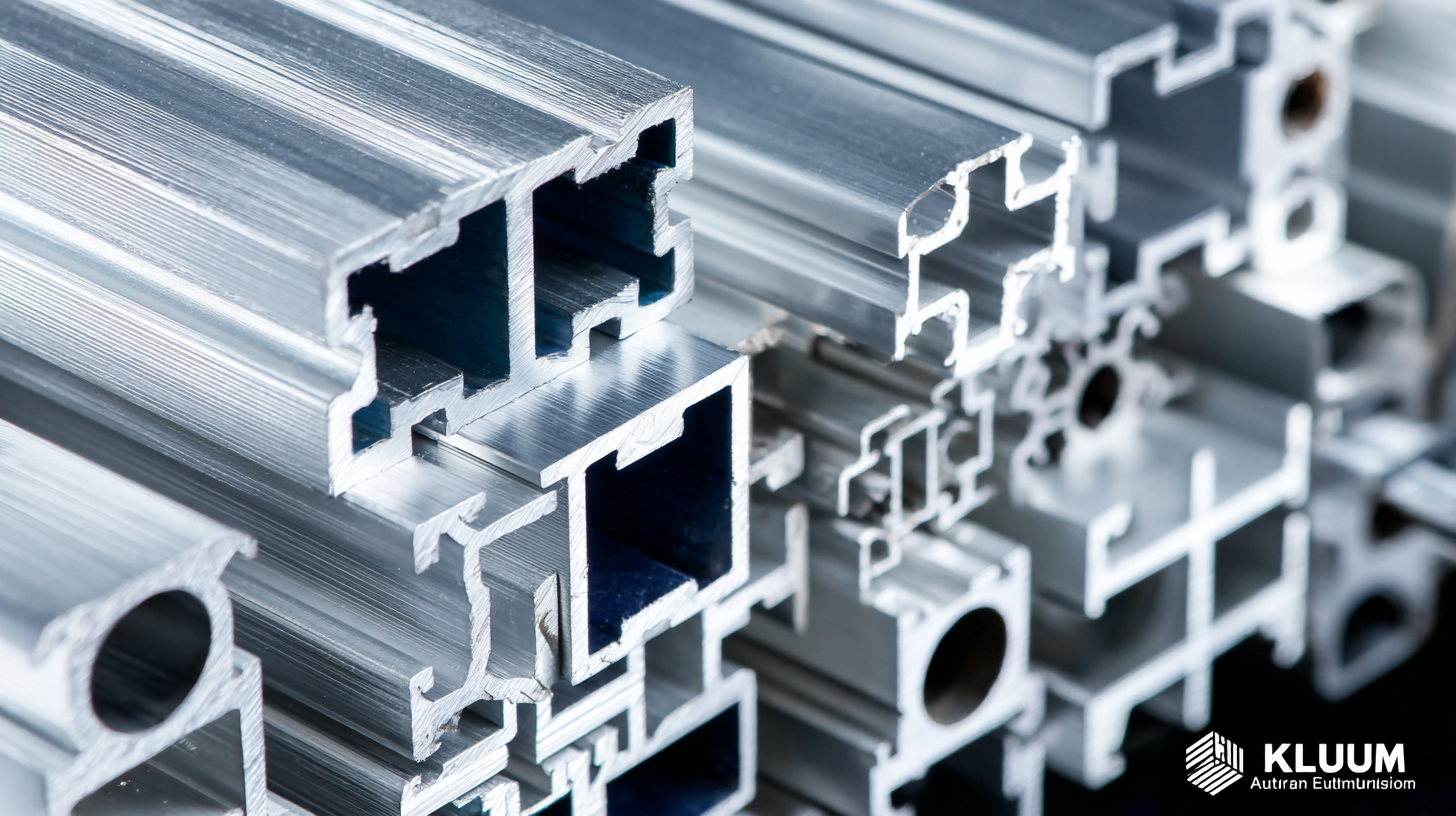

In the dynamic landscape of manufacturing, Aluminium Extrusion stands out as a pivotal process that fuels innovation across various industries, from aerospace to automotive and beyond. According to a report by MarketsAndMarkets, the global aluminium extrusion market is projected to reach USD 105.19 billion by 2025, growing at a CAGR of 5.6% from 2020 to 2025. This growth underscores the increasing demand for lightweight, durable, and versatile aluminium products. Selecting the right aluminium extrusion manufacturer is critical for businesses seeking effective solutions tailored to their specific needs. With many manufacturers vying for attention, particularly from top factories in China, it becomes essential to identify those that not only offer quality but also reliability and trust. This guide will delve into the essential criteria for selecting top aluminium extrusion manufacturers, ensuring that your projects are supported by expertise and excellence.

Aluminium extrusion is an essential process widely utilized across various industries, including automotive, construction, and electrical applications. As the market for aluminium extrusion continues to grow, understanding key concepts becomes increasingly vital for businesses seeking effective solutions. According to recent industry reports, the aluminium extrusion market is projected to reach a value of $44.7 million by 2025, expanding to $63.1 million by 2033, with a compound annual growth rate (CAGR) of 4.4%. This growth signals a robust demand for high-quality aluminium extrusions, driven by advancements in manufacturing techniques and materials technology.

Additionally, the aluminium extrusion sector is witnessing significant developments, such as the recent recertification of numerous plants under the Aluminium Stewardship Initiative (ASI) performance standards. These certifications highlight the industry's commitment to sustainable practices and high-quality production, which are crucial for manufacturers looking to stay competitive. Furthermore, the emergence of new players in the market, specifically in the aluminum extrusion tooling segment, indicates a healthy innovation environment, providing clients with diverse options to meet their specific needs. This evolving landscape reinforces the importance of selecting top aluminium extrusion manufacturers equipped to deliver effective and tailored solutions.

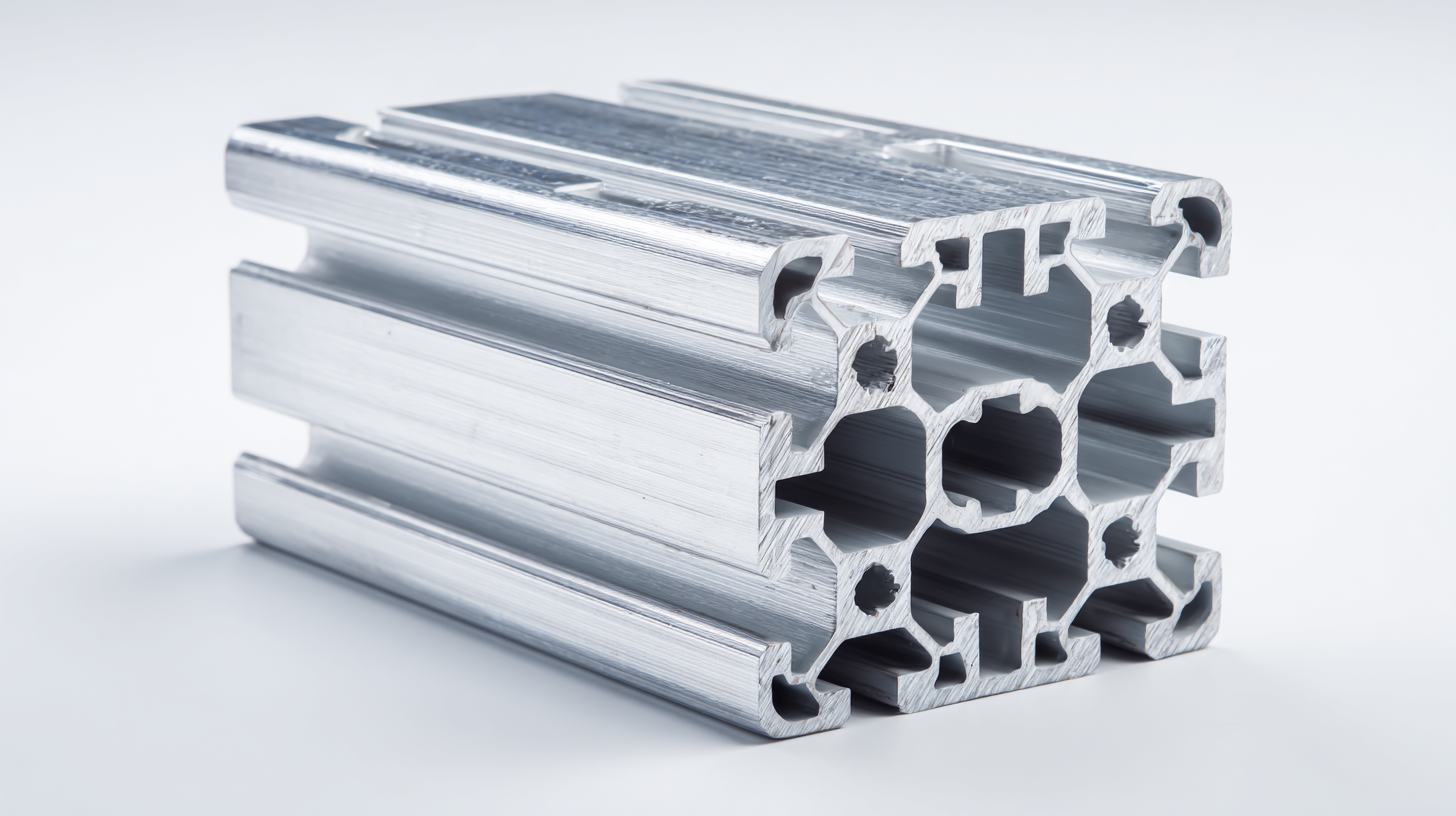

When selecting aluminium extrusion manufacturers, several critical factors should be taken into account to ensure optimal performance and product quality. Firstly, evaluate the manufacturer's experience and expertise in the industry. According to a report by the Aluminium Association, companies with over 15 years in the business are more likely to implement advanced processes and maintain high-quality standards, resulting in products that meet specific customer requirements. This experience often translates into better production efficiency and lower error rates.

Another essential consideration is the manufacturer's production capacity and technology. A survey conducted by Grand View Research indicates that the global aluminium extrusion market is projected to reach USD 93.43 billion by 2025, driven by demand in sectors like automotive and construction. Potential manufacturers should possess modern machinery and techniques to meet this growing demand efficiently. Additionally, assessing the supplier's ability to offer custom solutions is vital, as tailored products can enhance the overall performance of your applications, leading to a more competitive edge in the market.

When selecting an aluminium extrusion manufacturer, evaluating their capabilities is crucial to ensure they meet your specific needs. Quality is paramount; look for manufacturers that utilize stringent quality control processes and adhere to industry standards. Certifications like ISO 9001 can indicate a commitment to quality management systems, ensuring that you receive products that meet your specifications and are built to last. Additionally, consider the types of materials they use. Reputable manufacturers should offer high-grade aluminium options that enhance durability and functionality.

Technology also plays a vital role in the manufacturing process. Advanced machinery and state-of-the-art techniques can significantly impact production efficiency and precision. Manufacturers that invest in the latest extrusion and processing technologies are likely to produce higher quality extrusions with better surface finishes and tolerances. Furthermore, inquire about their capacity to handle varying sizes of orders, from small prototypes to large-scale productions. This flexibility can be essential for businesses looking to scale operations without compromising on quality or lead times.

Customization plays a pivotal role in aluminium extrusion solutions, making it essential for manufacturers to prioritize tailored options when addressing client needs. Unlike standard products, custom extrusions allow companies to specify their exact requirements, from profile dimensions to material properties and surface finishes. This level of personalization ensures that the final products not only meet performance specifications but also fit seamlessly into specific applications, thus enhancing overall efficiency and functionality.

Moreover, the benefits of customized aluminium extrusions extend beyond mere aesthetics; they can significantly impact production timelines and cost-effectiveness. By working closely with clients to develop bespoke designs, manufacturers can streamline their production processes, reducing lead times and minimizing waste. This collaborative approach fosters innovation, enabling clients to explore unique designs that can lead to competitive advantages in their respective markets.

Ultimately, choosing a manufacturer adept at providing custom solutions is vital for businesses seeking to optimize their operations and differentiate themselves in an increasingly competitive landscape.

When it comes to sourcing aluminum extrusions, building long-term partnerships with manufacturers is essential for achieving consistent quality and reliability. Establishing a strong relationship can streamline the procurement process and enhance collaboration on product development. Consider starting with an in-depth assessment of potential manufacturers. Research their production capabilities, quality control processes, and past performance with similar projects.

Tip: Always request samples before making bulk purchases. This allows you to evaluate the quality and consistency of their products firsthand. Pay attention to their responsiveness and willingness to accommodate custom requests, which can indicate their commitment to a successful partnership.

Communication is another vital aspect of a long-term relationship with your manufacturer. Regular dialogue helps align expectations and can lead to unforeseen improvements in your projects. Setting clear objectives and timelines from the beginning will facilitate a smoother collaboration and allow both parties to address issues proactively.

Tip: Utilize project management tools to keep track of progress and maintain open lines of communication. Establish regular check-ins to ensure any challenges are addressed promptly, fostering trust and transparency between your teams. This proactive approach will not only strengthen your partnership but also lead to more effective solutions tailored to your needs.