As the construction and design industries increasingly prioritize aesthetic appeal alongside functionality, Wood Grain Aluminum Tubes have emerged as a sought-after solution. These innovative materials blend the durability of aluminum with the natural beauty of wood grain finishes, making them ideal for a variety of projects ranging from residential buildings to commercial spaces. According to a recent market analysis by the Aluminum Association, the adoption of wood grain finishes in aluminum products has seen a 25% increase in the past five years, highlighting a growing trend in eco-friendly design solutions.

Industry expert Dr. Johnathan Reed, a leading figure in architectural materials research, emphasizes the value of this trend: “Wood Grain Aluminum Tubes not only offer remarkable resilience but also enable designers to achieve a warm, organic look that was previously unattainable with traditional metal tubing.” This versatility allows architects and builders to work creatively while maintaining structural integrity, making Wood Grain Aluminum Tubes an essential component of modern construction and design.

Incorporating Wood Grain Aluminum Tubes into your projects not only enhances their visual appeal but also aligns with sustainable practices that are increasingly demanded by consumers. With ongoing innovations and the rising popularity of these materials, understanding their benefits is crucial for anyone engaged in architectural design and construction.

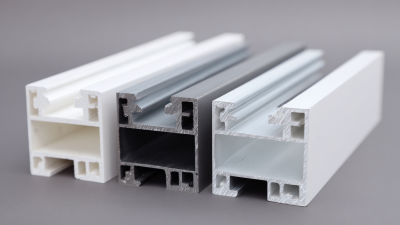

Wood grain aluminum tubes offer a unique blend of aesthetic appeal and practical functionality, making them an enticing choice for a variety of projects. Defined as aluminum tubes finished with a wood-like appearance, these products combine the lightweight properties of aluminum with the visual warmth and richness typically associated with natural wood. This innovative material is becoming increasingly popular in architectural and design applications, as it allows for the creation of structures that are both stylish and durable.

Recent industry reports highlight that the use of aluminum in construction continues to rise, with the market expected to reach $300 billion by 2025. This surge is attributed to aluminum's corrosion resistance and lightweight nature, further enhanced by the wood grain finish that appeals to eco-conscious consumers seeking sustainable design options. Projects like the installation at Cochin International Airport showcase the successful integration of traditional aesthetics with high-performance materials, signaling a shift towards multifunctional design solutions in urban development. Such advancements not only enhance the visual elements of a project but also contribute to its overall longevity and efficiency, solidifying the role of wood grain aluminum tubes in modern construction.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Made from aluminum, which offers high resistance to corrosion and weathering. | Long-lasting performance with minimal maintenance. |

| Aesthetic Appeal | Available in various wood grain finishes that mimic the look of natural wood. | Enhances the visual appeal of projects without the drawbacks of actual wood. |

| Lightweight | Aluminum is much lighter than traditional wood. | Easier handling and transportation for construction projects. |

| Eco-Friendly Options | Recyclable materials used in production. | Reduces environmental impact compared to conventional materials. |

| Versatility | Can be used in various applications including furniture, framing, and signage. | Suitable for a wide range of projects and designs. |

Wood Grain Aluminum Tubes have emerged as a popular choice in construction due to their aesthetic appeal and durability. One of the key advantages of using these tubes is their ability to mimic the natural appearance of wood while providing the strength and longevity of aluminum. According to a 2022 market report by TechNavio, the global aluminum market is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2025, driven in part by innovations such as wood grain finishes that combine the best features of both materials.

Another significant benefit is their resistance to environmental factors. Unlike traditional wood, which can warp, crack, or rot over time, wood grain aluminum tubes are resistant to moisture, pests, and UV rays. This property not only prolongs the lifespan of structures but also reduces maintenance costs. The Aluminum Association reported that materials with wood grain finishes can last up to 20 years longer than untreated wood, offering a more sustainable choice for architects and builders aiming for long-term project viability. Thus, integrating wood grain aluminum tubes into construction projects not only enhances visual design but also contributes to more sustainable building practices.

Wood grain aluminum tubes have gained popularity across various industries due to their aesthetic appeal and functional advantages. One of the primary applications is in the construction sector, where these tubes mimic the natural look of wood while offering enhanced durability and resistance to environmental factors. Architects and designers often integrate wood grain aluminum in window frames, railings, and cladding, providing a warm, rustic appearance without the maintenance challenges associated with real wood.

Additionally, wood grain aluminum tubes are widely used in furniture design. Their lightweight yet sturdy nature makes them ideal for creating table legs, shelving units, and decorative elements that require both style and strength. In the outdoor furniture market, these tubes stand out due to their resistance to weathering, ensuring that the furniture maintains its visual appeal over time while withstanding the elements. This versatility positions wood grain aluminum tubes as an excellent choice for both residential and commercial projects.

Wood grain aluminum tubes are becoming an increasingly popular choice for construction and design projects due to their unique combination of durability and aesthetic appeal. When comparing these modern materials to traditional options such as wood or vinyl, several key benefits emerge. Wood grain aluminum provides the warm, natural look of wood while maintaining the structural integrity that aluminum offers. This makes it less prone to warping, rotting, or fading, which are common issues associated with traditional wood.

In addition to the aesthetic advantages, wood grain aluminum is often more environmentally friendly than traditional materials. As the industry shifts towards sustainable building products, many manufacturers are now exploring plastic alternatives to traditional siding materials, which also presents opportunities for innovation in aluminum design. While wood and vinyl can suffer from size limitations and maintenance concerns, wood grain aluminum tubes can be produced in a variety of shapes and sizes, catering to diverse project requirements. The versatility and longevity of wood grain aluminum mean it provides a compelling choice for both residential and commercial applications, ensuring that projects look great for years to come without the hassle of intensive upkeep.

As we advance into 2025 and beyond, the aluminum industry is witnessing a significant shift towards sustainable materials, particularly in the form of wood grain aluminum tubes. According to a report by MarketsandMarkets, the global market for wood grain finish products is projected to reach approximately $8.8 billion by 2026, growing at a CAGR of 6.5%. This growth is driven by an increasing demand for innovative and eco-friendly construction materials that combine aesthetics with durability.

The wood grain aluminum tube stands out for its ability to mimic natural wood without the associated maintenance issues. This innovation is particularly appealing in architectural applications where aesthetics and longevity are crucial. Furthermore, a study conducted by Smithers Pira indicates that consumers are increasingly preferring products with a lower carbon footprint, with 75% of respondents saying they would choose eco-friendly materials for their building and construction projects. This trend signals that wood grain aluminum tubes not only meet consumer preferences but also align with global sustainability goals, making them a viable choice for future construction projects.