In the construction industry, the versatility of a Wooden Aluminium Round Tube is often underestimated. As experts suggest, this innovative material combines the warmth of wood with the strength of aluminum. According to Dr. Emily Hart, a leading material scientist, "The Wooden Aluminium Round Tube is reshaping modern architecture by offering both aesthetic appeal and structural integrity."

This hybrid product's unique properties enable it to be used in various applications, from roofing to interior design elements. It brings a natural feel to urban settings while maintaining durability. Homebuilders are increasingly opting for the Wooden Aluminium Round Tube to create sustainable yet stylish structures.

However, the journey of integrating this material into construction is not without challenges. Some may question the balance between aesthetics and functionality. As Dr. Hart points out, “Finding the right blend can be an ongoing experiment.” Designers often face limitations in optimizing its use. The growth of the Wooden Aluminium Round Tube industry invites reflection on how we approach innovation in construction.

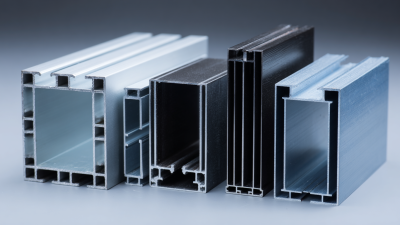

A wooden aluminium round tube combines two materials: wood and aluminium. This hybrid design offers unique advantages. The outer layer, typically made from wood, provides aesthetic appeal and warmth. The inner aluminium structure adds strength and durability. This combination makes it suitable for various applications in construction.

In construction, wooden aluminium round tubes serve as support structures. They can be used for railings, frames, or decorative pillars. The natural look of wood complements modern designs. Besides, the lightweight nature of aluminium makes installation easier. Balancing beauty and function, these tubes are increasingly popular.

Tip: When selecting wooden aluminium round tubes, consider the intended use. Ensure the dimensions meet your project needs. Also, check for quality and finish. A well-finished tube reduces maintenance.

It's important to note that not all wooden aluminium tubes are created equal. Variations in wood grain or aluminium quality may impact performance. Inspect these details carefully before use. Remember, small imperfections in the material can affect overall strength. Prioritize quality for safety and longevity in construction projects.

Wooden Aluminium Round Tubes combine the strength of aluminum with the classic warmth of wood. The structure typically features an aluminum core enveloped in a wooden layer, providing durability and aesthetic appeal. According to a report by the International Journal of Construction Materials, these tubes can withstand significant stress, making them suitable for various applications in construction.

The composition of Wooden Aluminium Round Tubes allows for versatility. The aluminum core contributes to lightweight properties and resistance to corrosion. The wooden exterior offers traditional visual appeal, allowing architects to integrate these materials into designs that require a natural look. Some industry experts estimate that the use of these tubes can reduce overall construction weight by up to 30%. However, the reliance on specific wood types can lead to inconsistencies in appearance and durability.

While Wooden Aluminium Round Tubes present advantages, there are drawbacks to consider. The bonding of wood to aluminum can be sensitive to temperature changes, leading to potential expansion issues. Additionally, sourcing high-quality wood can be challenging, impacting availability. Data from the Global Construction Industry Report highlights that over 40% of construction projects face delays due to material inconsistencies, indicating the importance of careful material selection and quality assurance in projects using these hybrid tubes.

Wooden aluminium round tubes combine the aesthetics of wood with the durability of aluminium. This unique blend offers several advantages in construction. Their lightweight nature makes them easy to handle. Builders can transport and maneuver these tubes with minimal effort. The visual appeal of wood also allows for creative designs in various architectural styles.

Another benefit is strength. These tubes provide significant structural support. They resist bending and warping, unlike traditional wood. This reliability makes them ideal for load-bearing applications. However, using wooden aluminium tubes may present challenges. The fabrication process can be complex, requiring skilled workers. Improper installation could compromise their effectiveness.

Moreover, these tubes can be more expensive than conventional materials. Budget constraints might limit their use on certain projects. The decision to use wooden aluminium round tubes should involve careful consideration. Nonetheless, when used appropriately, they can enhance both function and beauty in construction.

Wooden aluminium round tubes combine the natural aesthetics of wood with the durability of aluminum. They are uniquely versatile in construction projects. One of their most common applications is in interior design. Designers often use these tubes as structural elements in open spaces, allowing for an airy feel, blending functionality with style.

In outdoor constructions, wooden aluminium round tubes are popular for railings and support structures. Their resistance to weather makes them ideal for gardens and patios. At times, the finish may wear off in harsh climates, requiring maintenance and occasional refinishing. This reality checks the initial perception of low upkeep.

Moreover, they work well in furniture design, offering creative support for tables and chairs. However, improper coupling with other materials can lead to instability. A careful examination of joint techniques is crucial. So, while wooden aluminium round tubes have great potential, they pose challenges that require thoughtful solutions.

Wooden aluminium round tubes are gaining popularity in construction due to their unique combination of strength and lightweight properties. However, maintenance is crucial for preserving their functionality and appearance. Regular inspections should be conducted to detect any signs of wear or damage. According to industry reports, up to 30% of structural failures happen due to inadequate maintenance practices.

Cleaning is equally important. When dirt accumulates, it can lead to corrosion in the aluminium layers. A simple mixture of mild soap and water, applied with a soft cloth, can keep the tubes looking new. However, DIY cleaning may sometimes scratch the finish, highlighting the need for professional care. Maintenance schedules should ideally be documented, but many contractors overlook this step, leading to unexpected costs.

For those involved in construction, understanding these needs is vital. The longevity of wooden aluminium round tubes can exceed ten years with proper care. Yet, the reality is that many sites fail to adhere to recommended maintenance practices. Awareness of this gap may lead to changes in project management. Regular training for workers on the importance of maintenance can significantly reduce the risk of structural failure.

| Dimension | Weight (kg/m) | Material Type | Common Applications | Maintenance Tips |

|---|---|---|---|---|

| 20mm x 15mm | 0.45 | Wood-Aluminium Composite | Frame construction, furniture design | Clean regularly, avoid moisture |

| 25mm x 20mm | 0.55 | Wood-Aluminium Composite | Support beams, wall panels | Seal with varnish, inspect for damage |

| 30mm x 25mm | 0.70 | Wood-Aluminium Composite | Railings, decorative accents | Avoid abrasive cleaners, store properly |

| 40mm x 35mm | 0.90 | Wood-Aluminium Composite | Structural supports, exterior design | Regular inspection, buff out scratches |