Anodized aluminum profiles: durability and design

In the world of construction and manufacturing, Anodized Aluminum profiles stand out as a versatile and durable material. But what exactly is anodized aluminum profiles? And why is it so popular? Let’s take a deeper look.

Anodized aluminum Extrusions are aluminum extrusions that have been subjected to an electrochemical process called anodizing. This process forms a protective oxide layer on the surface of the aluminum, enhancing its resistance to corrosion, wear and discoloration. The anodizing process involves immersing the aluminum in a bath of electrolyte and passing an electric current through it, which causes the aluminum's natural oxide layer to thicken.

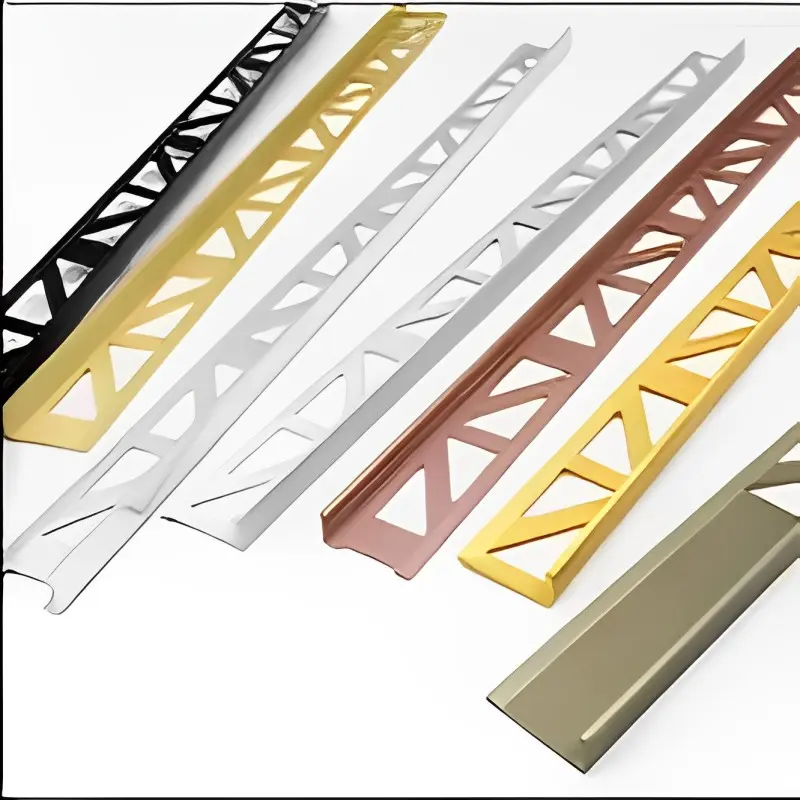

There are several ways to tell if aluminum is anodized. Visually, anodized aluminum has a distinctive look with a uniform color and a smooth, often shiny surface. Its color varies from classic silver to black, gold, gray, and many other custom colors. Anodized aluminum also has excellent color retention, maintaining its appearance over time even when exposed to adverse weather conditions. Additionally, the surface of anodized aluminum is harder than non-anodized aluminum, making it more resistant to scratches and abrasions. Using a multimeter to test the surface or performing a chemical test are other ways to tell if aluminum is anodized.

Anodized aluminum profiles have a range of excellent properties. They have excellent corrosion resistance, making them suitable for both indoor and outdoor applications. Anodized aluminum surfaces are also UV resistant, preventing fading and discoloration caused by sunlight exposure. In addition, anodized aluminum is lightweight and strong, with a high strength-to-weight ratio, which is particularly beneficial in structural applications.

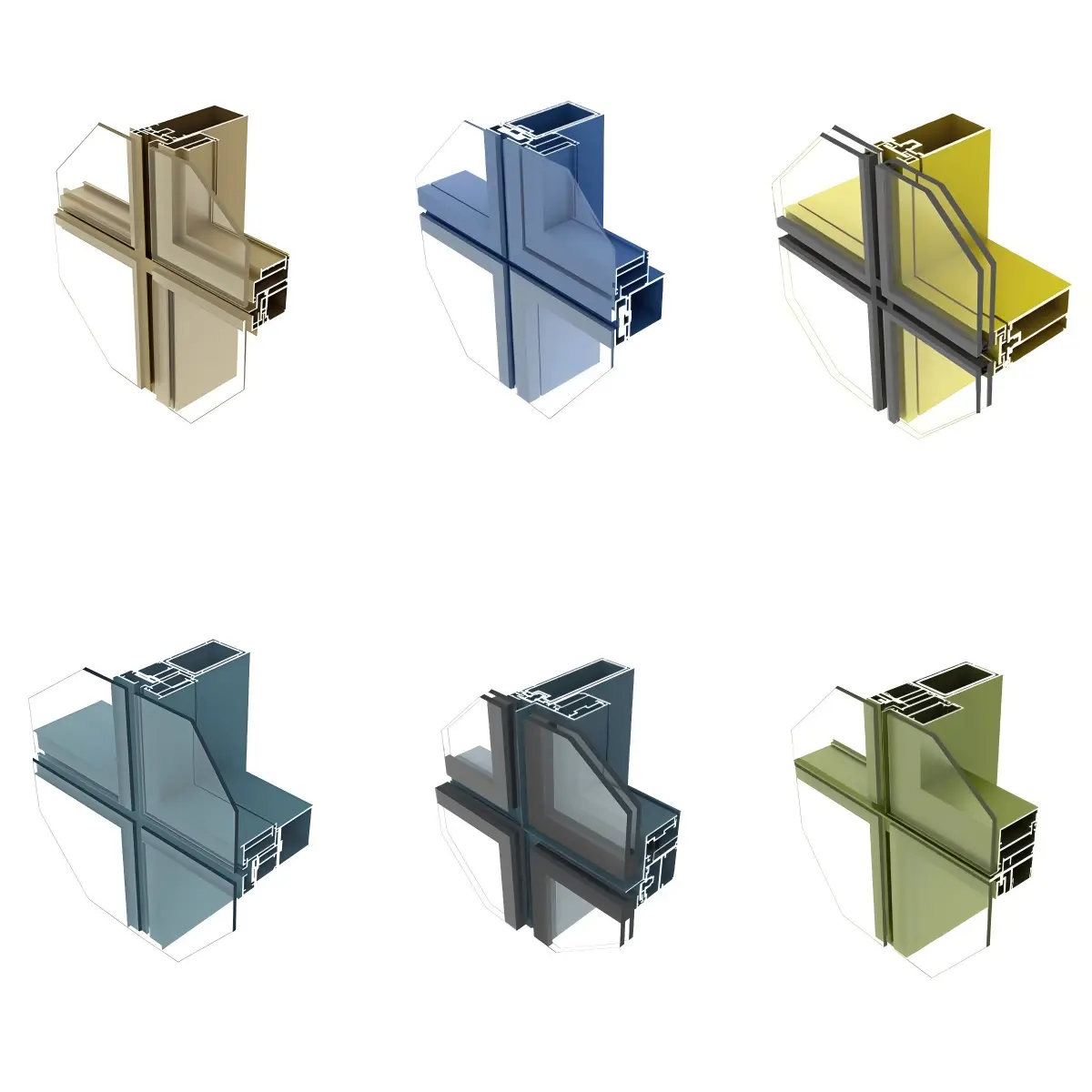

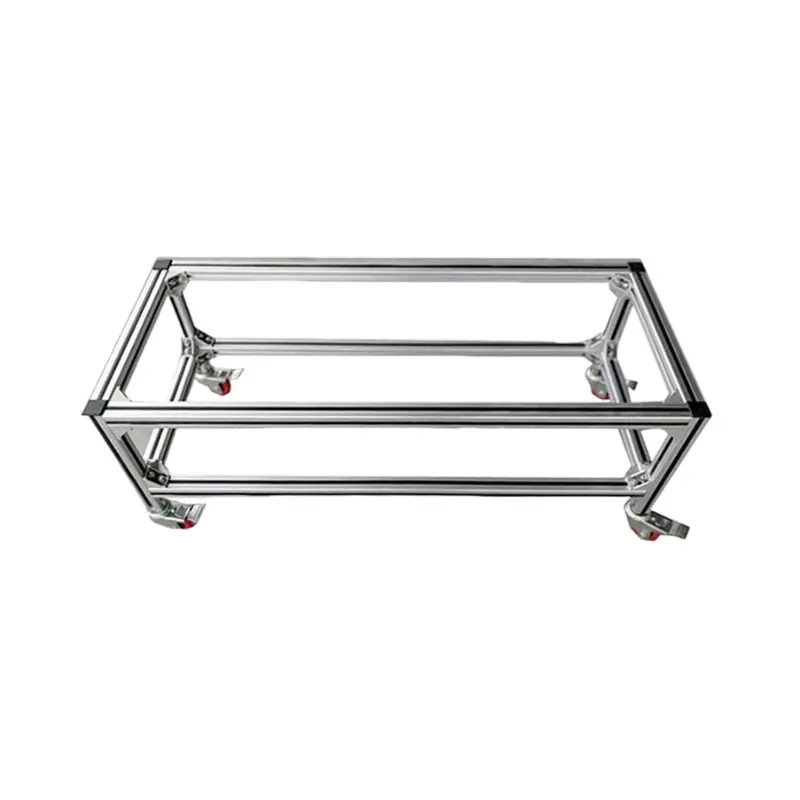

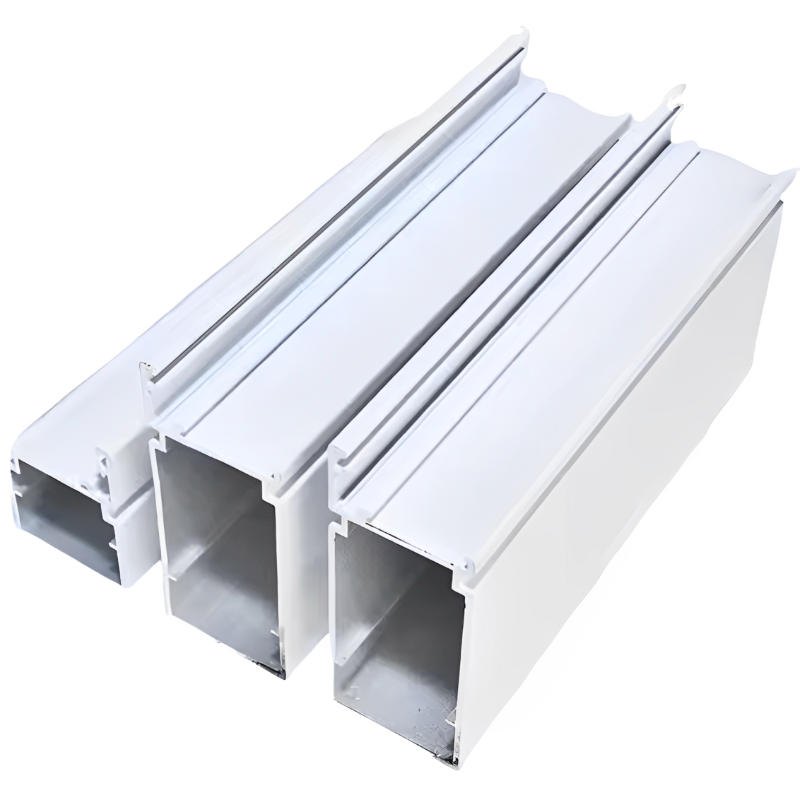

The applications of anodized aluminum profiles are very wide. In the construction industry, they are often used for window frames, curtain walls, and decorative elements. Their aesthetic appearance and durability make them ideal for residential and commercial buildings. In the transportation sector, anodized aluminum profiles can be used for automotive body panels, aircraft components, and marine accessories. The electronics industry also benefits from anodized aluminum, which is widely used in equipment housings due to its protective and aesthetic properties. In addition, consumer products such as lighting fixtures, furniture, and kitchenware also often use anodized aluminum profiles.

When selecting anodized aluminum extrusions, it is important to consider factors such as alloy type, anodizing thickness, color and finish, and dimensional tolerances. These factors can affect the performance and suitability of the extrusion for a particular project.

Anodized aluminum profiles are the best choice for numerous applications, offering a perfect blend of durability, aesthetics, and functionality. Their ability to withstand harsh conditions while maintaining their aesthetics makes them the material of choice across a variety of industries.