In today's increasingly interconnected world, the demand for high-performance building materials is driving the global sourcing of innovative solutions. Among these materials, the Thermal Break Aluminum Profile stands out for its exceptional energy efficiency and structural integrity. However, navigating the complexities of global sourcing poses unique challenges that manufacturers and builders must address. From variations in quality and standards to logistical hurdles and supply chain disruptions, understanding these challenges is essential for ensuring the successful integration of Thermal Break Aluminum Profiles into construction projects. This tutorial aims to explore the intricacies of sourcing these profiles internationally, shedding light on best practices and strategies to optimize procurement processes while mitigating risks associated with global supply chains. As we delve deeper into this topic, we will uncover insights that will empower industry stakeholders to make informed decisions and enhance the performance of their projects.

The sourcing of thermal break aluminum profiles is influenced by several key factors that vary significantly across global markets. One of the primary considerations is the regulatory landscape, which entails different standards for thermal efficiency and sustainability. Manufacturers must be adept at navigating these regulations to ensure compliance in their target markets, which can often lead to increased costs and extended lead times. This intricacy can complicate the sourcing process, as suppliers need to maintain certifications while still competing on price and quality.

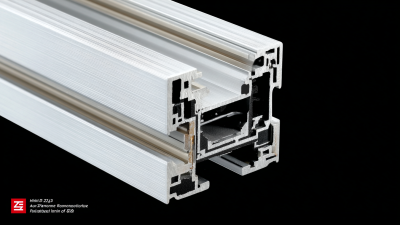

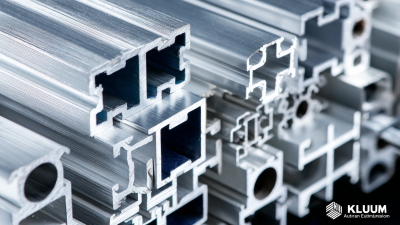

Another significant factor is the availability of raw materials and production capabilities. Regions prone to certain resource constraints may struggle to meet the demand for high-quality thermal break profiles. Additionally, the technological capabilities of suppliers play a crucial role in determining the technical specifications of the products they can offer. Effective communication and collaboration with suppliers are essential in overcoming these challenges, ensuring that stakeholders can align their sourcing strategies with local market demands and technological advancements. In this fast-evolving industry, staying informed about market trends and disruptions is vital for a successful sourcing strategy.

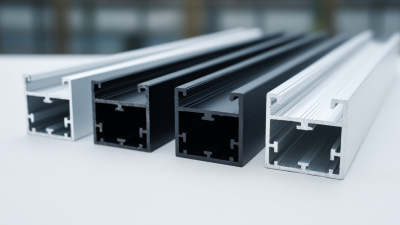

In the realm of global sourcing, the thermal break aluminum profile has emerged as a critical component in energy-efficient building designs. However, navigating the complexities of its supply chain poses several challenges that stakeholders must address. One of the primary issues is the inconsistency in raw material quality. Suppliers from different regions may utilize varying grades of aluminum or thermal break materials, potentially impacting the overall performance and durability of the final product. This inconsistency necessitates stringent quality control measures and thorough supplier audits, which can complicate sourcing strategies.

Another common challenge in the thermal break aluminum supply chain is the fluctuating prices of raw materials and logistics. Economic instability, geopolitical tensions, and global market demands can lead to unpredictable costs, making it difficult for manufacturers to maintain competitive pricing while ensuring product quality. Additionally, lead times can be extended due to delays in shipping and customs clearance, further complicating project timelines. As a result, companies must develop agile sourcing strategies that include diversified supplier networks and proactive risk management plans to effectively mitigate these challenges.

Global sourcing of thermal break aluminum profiles comes with its share of challenges, particularly due to fluctuating market conditions, varying quality standards, and logistical issues. According to a recent report by Global Market Insights, the aluminum profile market is expected to exceed $100 billion by 2026, highlighting the growing demand and the importance of strategic sourcing. This surge necessitates an astute approach to mitigate risks associated with quality and supply chain disruptions.

To minimize these risks, here are some best practices: First, conducting comprehensive due diligence on suppliers can significantly enhance the quality assurance process. Establishing long-term relationships with trusted manufacturers who adhere to international standards ensures a consistent supply of high-quality products. Second, implementing quality control measures through periodic audits and inspections allows companies to preemptively identify potential issues before they escalate into costly mistakes.

Proactive risk management strategies are essential. This can include diversifying the supplier base to mitigate dependency on a single source, thus reducing the impact of any disruptions. Moreover, leveraging market data and analytics can provide insights into pricing trends and economic conditions, enabling better decision-making in sourcing strategies. By adhering to these practices, companies can enhance their resilience and competitiveness in the dynamic landscape of aluminum profile sourcing.

In the modern landscape of aluminum profile sourcing, technology plays a pivotal role in streamlining processes and overcoming the challenges associated with thermal break aluminum profiles. As global demand for energy-efficient building materials rises, the complexity of sourcing these specialized products increases. Advanced software solutions now allow manufacturers and suppliers to optimize their inventory management, ensuring that they can meet fluctuating market demands without compromising on quality.

Moreover, technology enhances communication between stakeholders in the sourcing chain. Real-time data analytics and collaborative platforms facilitate transparency and improve decision-making. By leveraging these technological advancements, companies can minimize lead times, reduce costs, and enhance product quality. This not only improves operational efficiency but also aligns sourcing practices with sustainability goals by ensuring that only the most efficient thermal break profiles are selected for production, ultimately contributing to greener building solutions worldwide.

| Challenges | Impact on Sourcing | Technological Solutions | Efficiency Improvement |

|---|---|---|---|

| High Transportation Costs | Increased overall sourcing costs | Real-time shipping analytics | 15% reduction in logistics costs |

| Quality Control Issues | Returns and defects increase | Automated quality inspection systems | 30% reduction in defects |

| Supplier Reliability | Delayed deliveries | Blockchain for supplier authentication | 20% faster delivery times |

| Market Fluctuations | Price volatility | Predictive analytics | Stabilized pricing trends |

| Regulatory Compliance | Risk of sanctions | Compliance management software | Reduced non-compliance incidents |

The global market for thermal break aluminum profiles is witnessing transformative trends fueled by increasing sustainability demands and energy efficiency standards. According to a report by ResearchAndMarkets, the thermal break aluminum profile market is expected to grow at a CAGR of 5.7% from 2023 to 2030. This growth is driven by the rising awareness of energy-efficient building materials that can reduce thermal transmittance in construction. As many countries tighten their energy regulations, manufacturers are investing in advanced materials and technologies to meet these standards, ensuring better performance in thermal insulation.

Moreover, the push for green building certifications, such as LEED and BREEAM, is significantly influencing procurement strategies in the thermal break aluminum profile sector. A study by the Global Aluminum Institute indicates that buildings with high thermal performance can reduce energy consumption by up to 30%, which aligns well with net-zero initiatives across various regions. As architects and developers increasingly prioritize environmentally responsible materials, sourcing strategies are evolving. International suppliers are becoming more competitive by integrating innovative solutions into their product lines, enhancing not only the energy efficiency of buildings but also the aesthetic appeal of architectural designs.