In today’s rapidly evolving construction and design landscape, the quest for effective and sustainable building materials has never been more critical. One such area of focus is the development of innovative alternatives to traditional **heat insulation aluminum profile** solutions. While aluminum profiles have long been favored for their lightweight and durable characteristics, the rising demand for energy efficiency and environmental sustainability is prompting architects and builders to explore new materials and technologies that can offer enhanced thermal performance. This ultimate guide delves into the latest advancements and alternatives in heat insulation, examining both their benefits and potential drawbacks, and aims to provide industry professionals with valuable insights into how these innovations can transform building practices. Join us as we uncover the future of heat insulation and its role in creating more energy-efficient and sustainable structures.

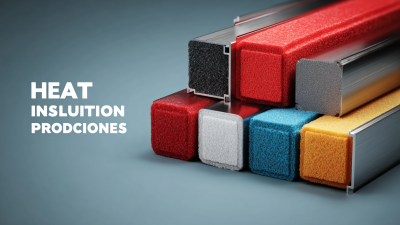

In recent years, the demand for effective heat insulation solutions has led to the exploration of innovative materials specifically designed for aluminum profiles. Traditional methods often rely on standard insulation materials, but the industry is experiencing a shift towards more advanced options that enhance thermal performance while maintaining structural integrity. Emerging alternatives include aerogels, phase change materials (PCMs), and bio-based composites, each offering unique properties that can significantly improve insulation efficiency.

Aerogels, for instance, are known for their exceptional thermal resistance and lightweight nature. These porous structures minimize heat transfer, making them ideal for enhancing the insulation capabilities of aluminum profiles in various applications. Similarly, phase change materials provide temperature regulation by absorbing and releasing thermal energy, thus stabilizing the internal environment of buildings and reducing energy consumption. On the other hand, bio-based composites, derived from renewable resources, not only contribute to environmental sustainability but also offer competitive thermal insulation properties, making them a promising choice for future applications in the construction sector.

As these innovative materials continue to evolve, the potential for transforming heat insulation strategies within aluminum profile manufacturing expands, paving the way for more sustainable and energy-efficient building practices.

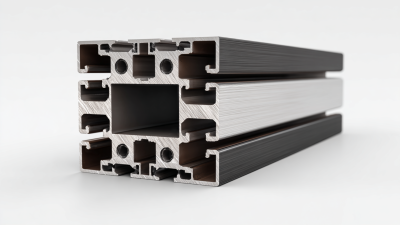

When comparing traditional insulation solutions to modern alternatives, it's essential to evaluate their effectiveness, energy efficiency, and environmental impact. Traditional heat insulation methods, such as fiberglass or foam board, have long been staples in the industry, providing a reliable barrier against heat transfer. However, these materials often come with limitations, including poor durability and environmental concerns related to production and disposal. In contrast, modern insulation solutions, such as vacuum-insulated panels and phase-change materials, offer enhanced energy efficiency and reduced thickness, making them ideal for space-constrained applications.

Tip: When selecting insulation materials, consider not only the R-value (thermal resistance) but also the longevity and adaptability of the material in various environmental conditions. This ensures that your investment pays off in the long run.

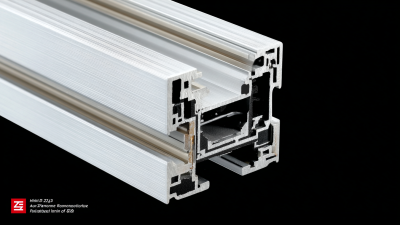

Furthermore, advancements in technology have led to innovative alternatives like heat insulation aluminum profiles. These profiles not only improve thermal efficiency but also provide structural support, making them a dual-purpose solution for modern construction. Their lightweight nature and recycled material options make them appealing from an ecological standpoint as well.

Tip: Always consult with a professional for a comparative assessment of insulation options tailored to your specific project needs, as this can significantly influence energy savings and overall building performance.

In the quest for more efficient heat insulation solutions, exploring alternatives to traditional aluminum profiles can lead to exciting innovations. This guide delves into alternative insulation techniques that not only enhance thermal performance but also contribute to sustainability. Begin by evaluating materials such as recycled fiberglass, cellulose, or even natural wool, which can offer superior insulation properties while minimizing environmental impact.

Next, consider the installation process for these alternative materials. A step-by-step approach involves first assessing the specific insulation needs of your space, followed by the careful selection of the appropriate material. Preparing the site is crucial; ensure that all areas are clean and free of moisture to maximize the effectiveness of the insulation.

Once the material is chosen and the site is prepped, you can proceed with installation. Techniques may vary depending on the material, but common methods include spray applications for foam insulation or layering batt insulation for added efficiency. With these innovative alternatives, you'll not only optimize your insulation strategies but also embrace a greener approach to building design.

As the construction industry continues to evolve, the quest for more efficient heat insulation technologies is gaining momentum. Innovative alternatives to traditional aluminum profiles are emerging, aiming to enhance energy efficiency while reducing environmental impact. Future trends suggest a shift towards materials that not only provide superior thermal performance but also integrate seamlessly with sustainable building practices. This includes the use of bio-based composites and advanced polymers, which offer comparable insulation properties with significantly lower carbon footprints.

Moreover, advancements in nanotechnology are paving the way for smart heat insulation solutions. These intelligent materials can adapt to changing environmental conditions, optimizing energy use in real-time. The incorporation of phase-change materials (PCMs) in construction is another promising trend, allowing buildings to absorb, store, and release thermal energy as needed, thereby improving comfort levels and reducing reliance on traditional heating and cooling systems. As the industry embraces these cutting-edge technologies, the future of heat insulation in construction promises not only enhanced performance but also a strong alignment with global sustainability goals.

In recent years, the demand for innovative insulation solutions has surged, particularly in the construction and manufacturing sectors. A recent report by the International Energy Agency (IEA) highlights that buildings account for approximately 40% of global energy consumption, underscoring the critical need for effective heat insulation. Innovative alternatives to traditional aluminum profiles, such as those incorporating aerogel composites and phase change materials (PCMs), are gaining traction for their superior thermal performance. Aerogel, for instance, boasts an extraordinary thermal resistance, being 39 times more effective than traditional fiberglass insulation, which can lead to significant energy savings over a structure’s lifespan.

Case studies reveal the successful implementation of these advanced materials in various projects. A notable example can be found in a recent retrofitting project in Europe, where builders replaced conventional aluminum window frames with aerogel-integrated systems. This transition resulted in a 30% reduction in heat loss, translating into $1,200 in annual energy savings for the building's occupants. Furthermore, the integration of PCMs in façade systems has shown promise in maintaining consistent indoor temperatures, enhancing occupant comfort while minimizing energy consumption by up to 50% during peak periods, according to the latest findings presented by the Energy and Buildings journal. These innovative insulation solutions not only enhance building efficiency but also represent a significant step toward sustainability in the industry.