0102030405

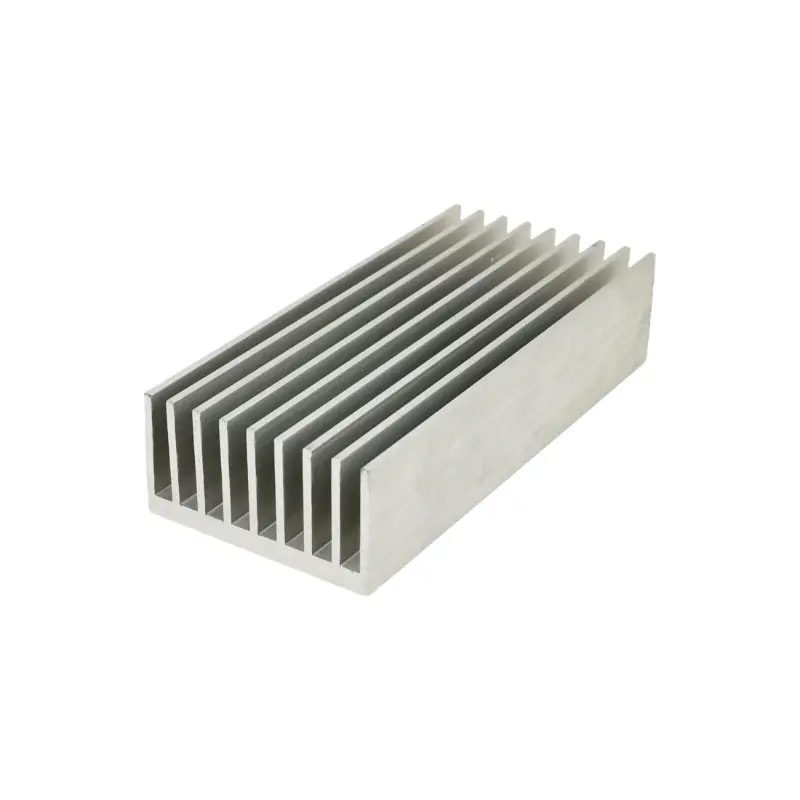

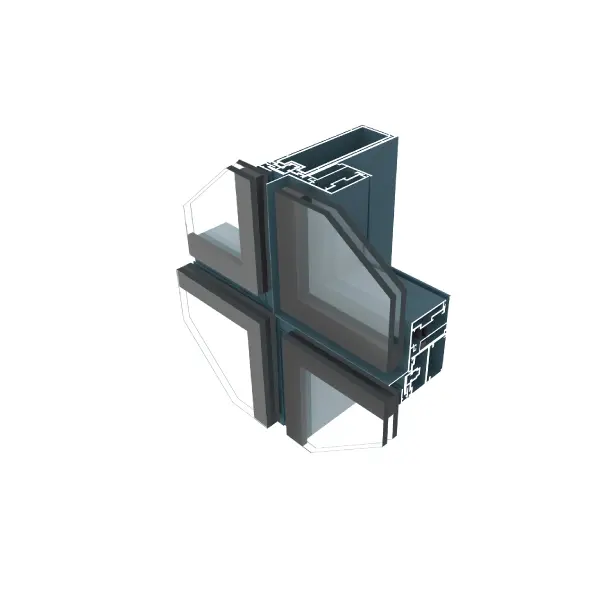

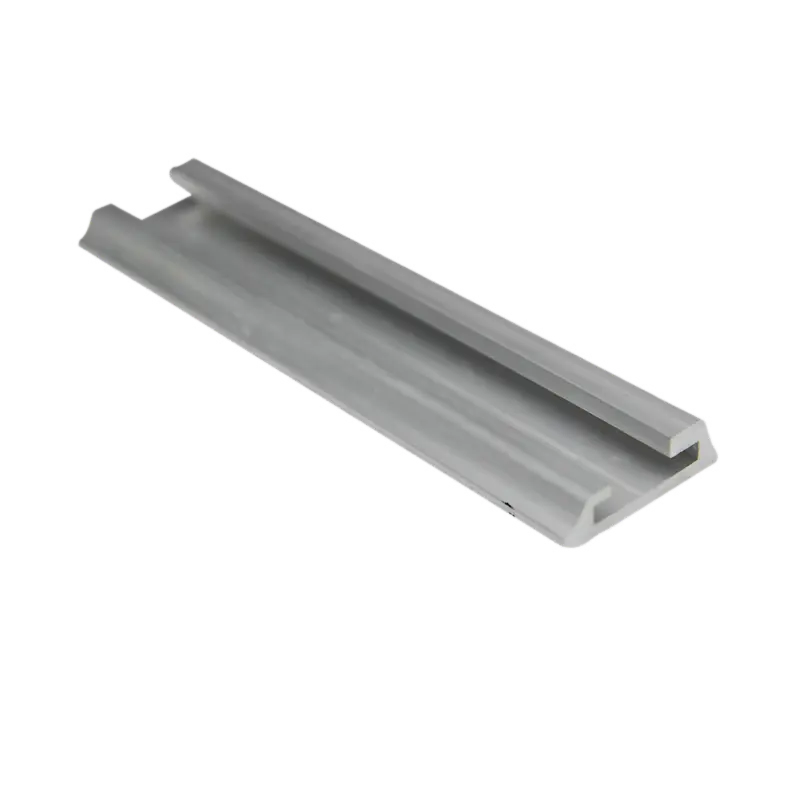

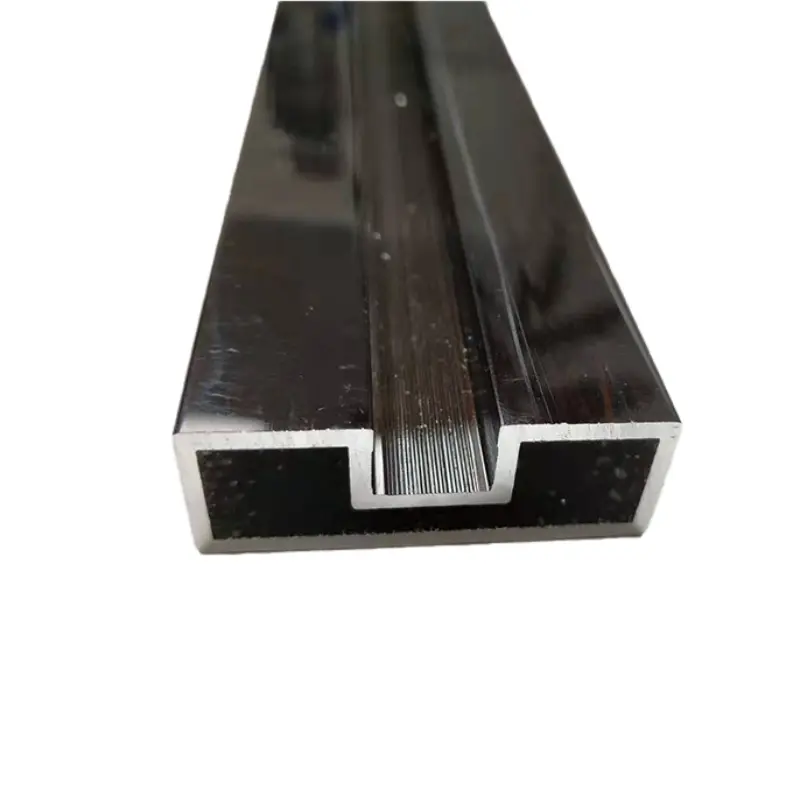

Door and window electrophoretic coating aluminum profile

Application

Discover the superior quality and performance of our electrophoretic aluminum profiles for windows and doors. These profiles stand the test of time and can withstand the most demanding environmental conditions. The electrophoretic coating process involves several key steps to ensure superior results.

First, the aluminum profiles undergo a thorough surface pretreatment, including cleaning and degreasing, to ensure optimal adhesion of the coating. The aluminum profiles are then immersed in an electrophoretic tank filled with water-based paint and an electric current is passed through the tank. Next, the coating particles migrate and deposit evenly on the profiles, forming a homogeneous coating with extremely low porosity. After spraying, the profiles are post-rinsed to remove excess paint and then cured, using heat to solidify the paint and adhere to the substrate. The resulting surface is highly durable and corrosion-resistant, and can withstand direct sunlight, high temperatures, thunderstorms, acid rain and other harsh environments. The film thickness of the electrophoretic coating is typically 15 to 25 microns, which can provide comprehensive protection for aluminum profiles.

Compared with traditional oxidation and spraying processes, electrophoretic coating provides superior protection and longer service life. Our aluminum profiles are widely used in high corrosion areas such as coastal areas and industrial areas. The service life of these profiles can reach 20 to 30 years, providing long-term value and reliability.

In addition to durability, our anodized aluminum profiles offer a wide range of color options to meet different aesthetic preferences. The coating process allows for a variety of finishes and effects, from high gloss to matte, from metallic luster to pearlescent luster. This flexibility makes our profiles versatile and can meet different architectural styles and design requirements. Whether you want to enhance the appearance of residential doors and windows, or seek a reliable solution for commercial and industrial buildings, our anodized aluminum profiles are your ideal choice.

They are both functional and beautiful, combining protection with visual appeal. In addition, we understand the importance of customization to meet specific project needs. We can produce profiles in a variety of sizes, shapes and colors according to your needs, ensuring that our products meet your unique design and functional specifications. Our commitment to quality is reflected in every stage of production. We strictly adhere to ISO standards and implement strict quality control processes to ensure the high performance and reliability of our products. From the selection of raw materials to the inspection of finished products, we ensure that nothing goes wrong. We also provide high-quality packaging services to ensure that the products are delivered to you intact.

In short, our electrophoretic aluminum profiles for doors and windows provide a cost-effective solution for protecting and enhancing the appearance of aluminum doors and windows. Its excellent corrosion resistance, uniform coating, long-lasting and durable surface treatment, and customizable options make it an ideal choice for a variety of applications. Choose our electrophoretic aluminum profiles to experience the perfect combination of durability, beauty, and performance for doors and windows.

| Brand Name | Luoxiang |

| Place of Origin | Foshan,China |

| Product name | Door and window electrophoretic coating aluminum profile |

| Material | 6063/6061 etc. |

| Technology | extrusion |

| Finishes | Anodising, electrophoretic coating, powder coating, etc. |

| Color | Customized |

| Delivery Date | 7-20 days after receipt of payment |